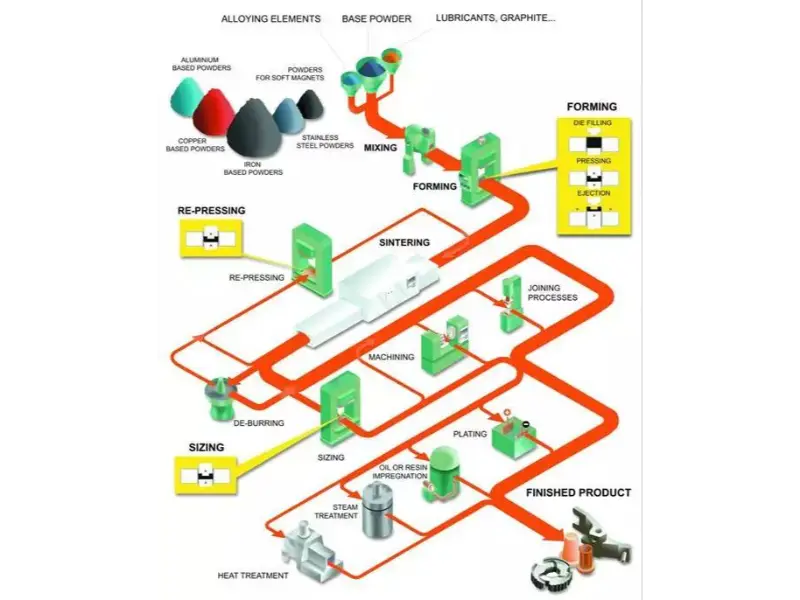

Powder Sintering: Advanced Techniques for High-Quality Metal Components Powder sintering is a transformative process in the world of metal manufacturing, offering a unique combination of efficiency, precision, and quality. As industries evolve and demand for high-performance components grows, powder sintering has emerged as a crucial technique. This article delves into the advanced techniques of powder sintering, exploring its applications, benefits, and the role of Welleshaft as a trusted global supplier and contract manufacturer in this field. Section 1: Understanding Powder Sintering Powder sintering is a process that involves heating powdered materials below their melting point to fuse them into a solid mass. This technique is integral in manufacturing high-quality metal […]

カテゴリーアーカイブ: Study cases and knowledge

Discover industriy trends, case studies, how-to guides, manufacturing processes and FAQs on Welleshaft’s Knowledge Hub—expert insights for engineers and sourcing professionals.

Welleshaft’s Study Cases and Knowledge page addresses key sourcing challenges, quality control hurdles, and real manufacturing pain points—helping buyers make smarter, faster decisions.

Sintered Filters: Precision Solutions for Filtration Needs Sintered filters are essential components in various industries due to their efficiency and reliability in filtering out impurities and contaminants. These filters are created using the sintering process, where metal or other materials are heated to form a porous structure that allows fluids or gases to pass through while trapping particles. This guide provides an overview of sintered filters, including their manufacturing process, benefits, applications, and advantages. Section 1: What Are Sintered Filters? Sintered filters are filtration devices made from metal, ceramic, or polymer materials that are processed through sintering. Sintering involves heating powdered materials below their melting point to bond the particles […]

Sintered Stainless Steel: High-Performance Solutions for Precision Engineering Sintered stainless steel is a game-changer in the world of precision engineering, offering unparalleled performance and reliability. This article explores the benefits and applications of sintered stainless steel, comparing it with traditional stainless steel and steel, and highlighting why Welleshaft is your go-to global supplier and contract manufacturer for these advanced materials. Section 1: What is Sintered Stainless Steel? Sintered stainless steel is created through a process known as sintering, where stainless steel powder is heated to just below its melting point to form a solid mass. This technique allows for precise control over the material’s properties and structure, resulting in products […]

Ceramic Powder Injection Molding: Precision Manufacturing Solutions Ceramic powder injection molding (CIM) is an advanced manufacturing process that enables the creation of intricate ceramic components with unparalleled precision and efficiency. This technique is widely used across various industries, including automotive, aerospace, electronics, and healthcare, due to its ability to produce complex shapes and high-performance materials. In this article, we will delve into the details of ceramic powder injection molding, explore the benefits it offers, and highlight why Welleshaft stands out as a trusted global supplier and contract manufacturer in this field. Section 1: What is Ceramic Injection Molding? Ceramic injection molding is a specialized process that combines the versatility of […]

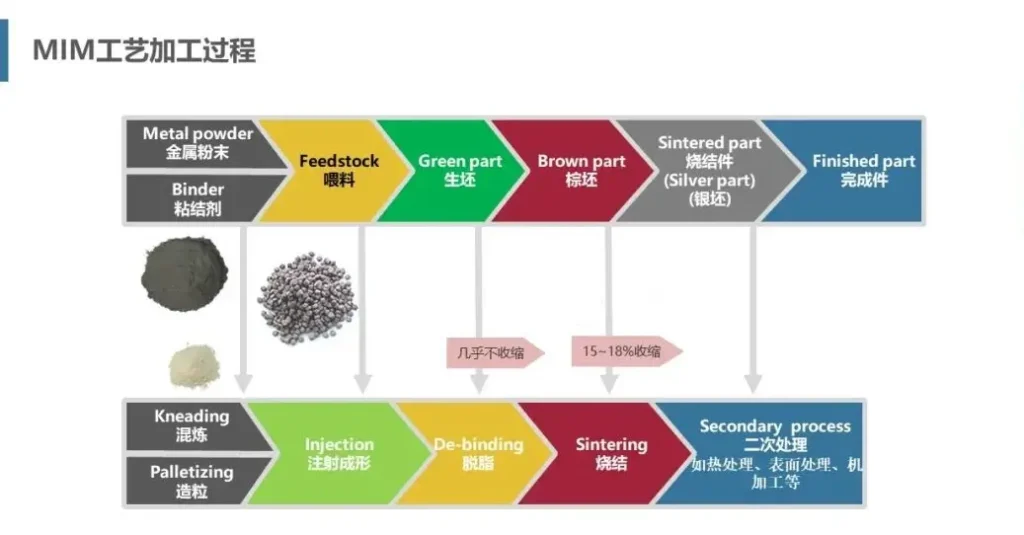

High-Quality Metal Injection Molding Materials for Precision Parts | Expert Manufacturing Solutions Metal Injection Molding (MIM) is a cutting-edge manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metal. This technology is ideal for producing complex and high-precision metal parts in large quantities. In this article, we’ll explore the various materials used in MIM, the benefits of the process, and why Welleshaft is your trusted global supplier and contract manufacturer for MIM solutions. Section 1: Introduction to Metal Injection Molding Metal Injection Molding (MIM) is a manufacturing process that allows for the production of intricate metal parts with high precision and consistency. This technique […]

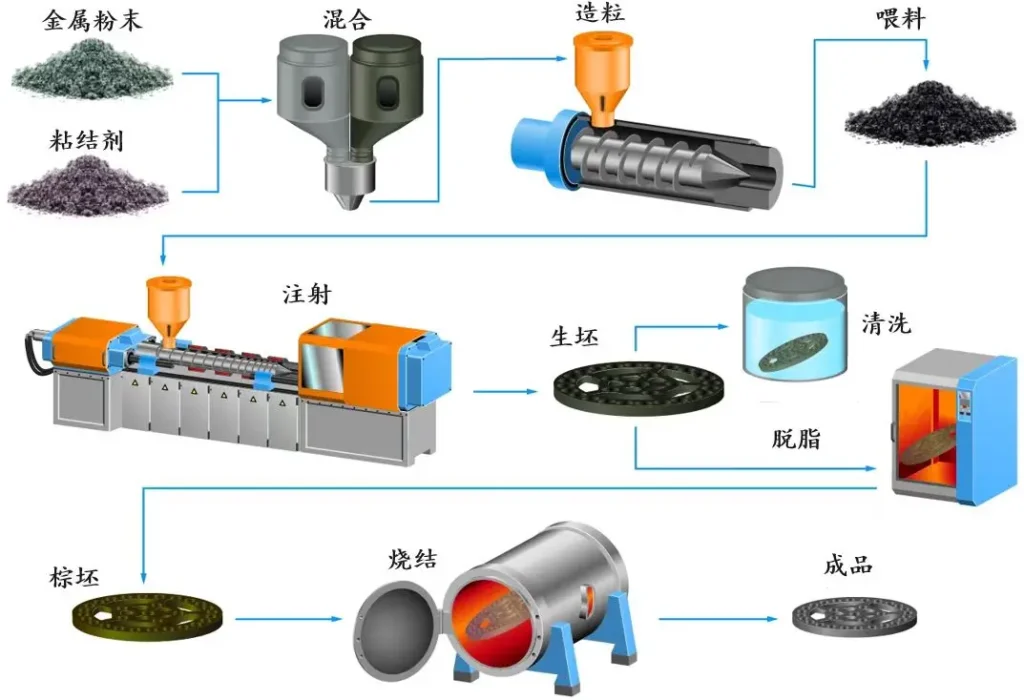

Metal Injection Molding Process | Precision Manufacturing Solutions The Metal Injection Molding (MIM) process is a revolutionary manufacturing technique that combines the benefits of plastic injection molding and powder metallurgy. This advanced method enables the production of high-precision, complex metal parts that are used in various industries, from aerospace to medical devices. In this article, we will explore the MIM process in detail, including its steps, benefits, and applications, and recommend Welleshaft as your trusted global supplier and contract manufacturer. Section 1: What is the Metal Injection Molding Process? The Metal Injection Molding (MIM) process is a manufacturing technique that produces intricate metal parts by injecting a mixture of fine […]

Metal Injection Molding vs Die Casting: Key Differences & Benefits Explained When choosing a manufacturing process for metal parts, two popular methods often come into consideration: Metal Injection Molding (MIM) and Die Casting. Each technique offers distinct advantages and is suited to specific applications. This article will delve into the key differences between Metal Injection Molding and Die Casting, exploring their processes, benefits, costs, and material options to help you determine the best method for your needs. 1. Metal Injection Molding vs Die Casting: Key Differences 1.1.Process Complexity: MIM: Involves multiple stages including feedstock preparation, injection molding, debinding, and sintering. This makes it suitable for complex parts with intricate details. Die […]

MIM Manufacturing: Advanced Metal Injection Molding Solutions for Precision Parts Metal Injection Molding (MIM) is an innovative manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of powder metallurgy. This advanced technique is particularly useful for producing small, intricate metal parts with high precision. In this article, we will explore the MIM manufacturing process, its benefits, and applications, and highlight Welleshaft as a trusted global supplier and contract manufacturer for all your MIM needs. What is MIM in Manufacturing? Metal Injection Molding (MIM) is a manufacturing process that involves mixing metal powders with a binder material to create a feedstock. This feedstock is then […]

Powder Injection Molding: Precision Manufacturing for Complex Components | Top PIM Solutions Powder Injection Molding (PIM) is a groundbreaking manufacturing technique that merges the versatility of plastic injection molding with the material flexibility of powder metallurgy. This method is particularly beneficial for producing small, complex, and high-precision components from various materials, including metals and ceramics. In this article, we will delve into the powder injection molding process, its advantages, and its applications in various industries. We will also address some frequently asked questions to provide a comprehensive understanding of PIM. Section 1: What is Powder Injection Molding? Powder Injection Molding (PIM) is a manufacturing process that involves injecting a mixture […]

Precision Metal Molding Solutions | High-Quality Metal Molding Services Metal molding is a vital manufacturing process, providing high-precision and complex metal parts for various industries. In this article, we’ll delve into the different types of metal molding processes, their advantages, applications, and compare them to other metal forming methods. We’ll also explore key aspects of metal molding, such as equipment and materials, and address common questions related to the process. Section 1 : Introduction 1.1.What is Molding in Metal? Molding in metal refers to the process of shaping metal parts by using molds. These molds can be made from different materials such as sand, clay, or metal itself. The process […]