Brass Forging: A Comprehensive Guide Brass forging is a crucial process in manufacturing high-quality brass components used in various applications. Whether you’re a manufacturer, engineer, or hobbyist, understanding brass forging and its benefits can help you make informed decisions about purchasing forged brass parts. In this article, we’ll explore everything you need to know about brass forging, including the differences between hot and cold forging, and what to consider when buying forged brass products. Frequently Asked Questions (FAQs) about Brass Forging 1. What is brass forging? Brass forging is a metalworking process where brass is shaped using compressive forces. This process typically involves heating the brass to make it more malleable and then […]

カテゴリーアーカイブ: Study cases and knowledge

Discover industriy trends, case studies, how-to guides, manufacturing processes and FAQs on Welleshaft’s Knowledge Hub—expert insights for engineers and sourcing professionals.

Welleshaft’s Study Cases and Knowledge page addresses key sourcing challenges, quality control hurdles, and real manufacturing pain points—helping buyers make smarter, faster decisions.

Dear Valued Customers, As the Mid-Autumn Festival approaches, we want to extend our heartfelt wishes for peace, prosperity, and happiness to you and your family during this festive season. May the full moon bring harmony and joy to your home. At Welleshaft, we deeply appreciate your continued trust and support. We remain committed to providing innovative solutions for your business with our broad range of high-quality products. Our expertise covers: Wear-resistant and corrosion-resistant materials for demanding environments. Special alloys components tailored for durability and performance. Rubber and plastic components designed for various industrial applications. Non-ferrous metals components crafted for precision and reliability. Standard mechanical components, fasteners, and core transmission parts […]

Customer Satisfaction Feedback: The Key to Success in Contract Manufacturing In the fast-evolving world of manufacturing, customer satisfaction is the driving force behind business growth. For industries relying on contract manufacturing, ensuring customer needs are met is crucial to success. From CNC machining manufacturers to medical device contract manufacturing and cosmetics contract manufacturing, maintaining high levels of satisfaction through precision, quality, and reliability is essential. In this article, we will explore the importance of customer feedback in the manufacturing industry, how it can help improve services, and why Welleshaft stands out as a trusted global supplier and contract manufacturer. The Role of Customer Satisfaction in Contract Manufacturing Customer satisfaction is […]

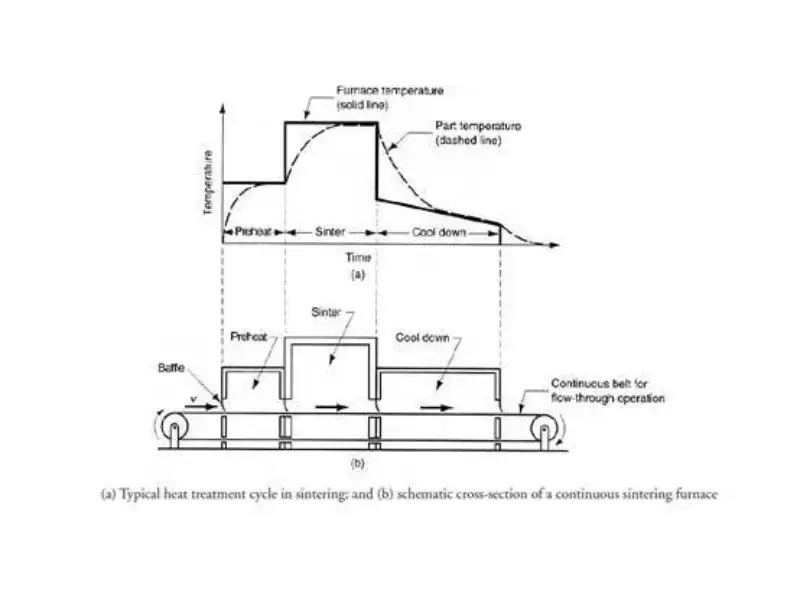

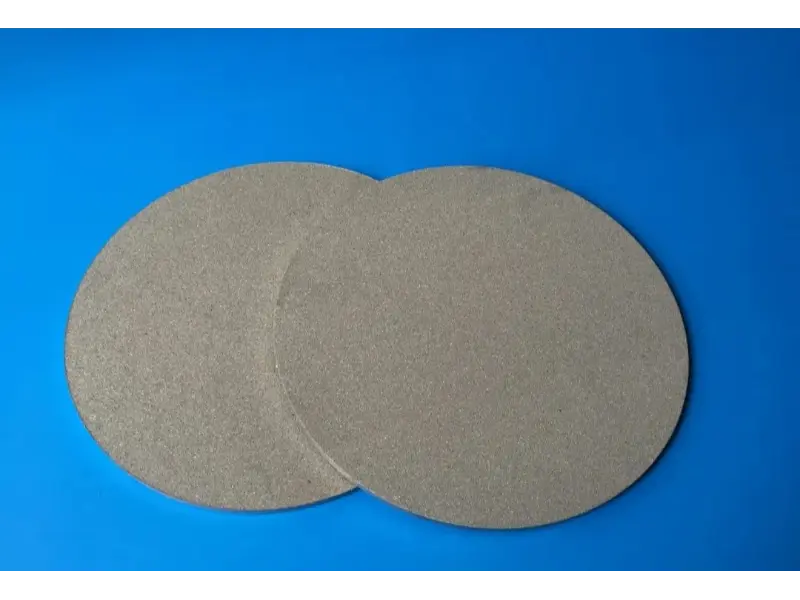

Advanced Powder Metallurgy Techniques & Applications | Precision Metal Forming Powder metallurgy (PM) has revolutionized the manufacturing industry by enabling the production of complex and high-performance components with precision and efficiency. This article explores the advanced techniques and applications of powder metallurgy, emphasizing its role in precision metal forming. We will delve into the process of sintering in metallurgy, the benefits of powder metallurgy, and why it is a critical process in various industries. Section 1: Introduction 1.1. What is Powder Metallurgy? Powder metallurgy (PM) is a manufacturing process that involves the shaping of metal powders into desired forms and then sintering them to create solid, high-strength components. This method is […]

Section 1: Introduction to Metal Sintering Metal sintering is a pivotal process in manufacturing precision components, utilizing powdered metals to create durable and complex parts. This article explores the various facets of metal sintering, highlighting its applications, benefits, and the expertise offered by Welleshaft as a leading global supplier in this field. 1.1. Understanding the Metal Sintering Process Metal sintering involves compacting and forming metal powders under controlled temperatures and pressures. This process results in sintered metal parts that exhibit high strength, precision, and often intricate geometries that are difficult to achieve through traditional manufacturing methods. Section 2: Types of Metal Sintering Processes Metal sintering encompasses various methods, each suited to […]

High-Performance Sintered Bearings | Durable & Efficient Solutions for All Applications In today’s demanding industrial environment, selecting the right bearing type is crucial to ensure the reliability, efficiency, and longevity of machinery and equipment. Sintered bearings are among the most sought-after solutions, known for their durability, self-lubricating properties, and versatility. In this article, we’ll explore the benefits of sintered bearings, delve into their applications, and highlight why Welleshaft stands out as a trusted global supplier and contract manufacturer of these high-performance components. Section 1: What is a Sintered Bearing? Sintered bearings are produced through a process known as sintering, which involves compacting metal powders under high pressure and then heating […]

High-Performance Sintered Gears: Durable & Precise Gear Solutions In the world of precision engineering, sintered gears stand out for their remarkable performance and durability. These gears, created through powder metallurgy, offer a unique blend of strength and cost-effectiveness that sets them apart from traditionally machined gears. In this article, we will explore the advantages of sintered gears, how they are manufactured, and why Welleshaft is your ideal partner for high-quality sintered gear solutions. Section 1: What Are Sintered Gears? Sintered gears are components created through a process known as powder metallurgy. This method involves compressing powdered metal into a mold and then heating it to a temperature where the particles […]

High-Quality Sintered Parts: Precision Engineered Components for Industrial Applications In the world of industrial manufacturing, the quest for precision and efficiency drives the need for high-quality components. One of the key players in this domain is sintered parts, which offer remarkable advantages in various industrial applications. This article delves into the significance of sintered metal parts, their manufacturing process, and their applications, while recommending Welleshaft as the trusted global supplier and contract manufacturer for these components. Section 1: What Does “Sintered” Mean? Sintering is a process used to create solid materials from powders by applying heat or pressure without melting the powder. This process binds the particles together to form […]

Powder Compaction: Expert Techniques & High-Quality Solutions for Optimal Results In the manufacturing industry, powder compaction plays a crucial role in shaping and forming materials with precision. This technique is widely used in various sectors, including automotive, aerospace, electronics, and more, to create components with complex geometries and high strength. Understanding the nuances of powder compaction and employing the right techniques can lead to significant improvements in product quality and manufacturing efficiency. In this article, we will delve into the essentials of powder compaction, explore the various methods used, and highlight how partnering with a trusted global supplier like Welleshaft can elevate your manufacturing capabilities. Section 1: What is Powder […]

Powder Forming: Advanced Techniques & Applications in Metal Sintering In the evolving world of manufacturing, powder forming has emerged as a cornerstone technique, particularly in metal sintering processes. This advanced method allows for the precise shaping of metal powders into robust and intricate parts, making it a preferred choice in industries that demand high-quality, high-performance components. This article delves into the advanced techniques and applications of powder forming, highlighting its significance in modern manufacturing. Section 1: What is Powder Forming? Powder forming is a manufacturing process that involves the compaction of metal powders into a desired shape, followed by sintering to form a solid piece. This process enables the creation of […]