Celebrate National Day with Welleshaft Dear Valued Customers, As we celebrate the National Day, WELLE Teams would like to extend our best wishes for peace, prosperity, and success to you and your team. This holiday represents a time of pride and progress, and we are proud to support your business with our high-quality, precision-engineered components. Welle’s manufacturing capabilities ensure that we meet your diverse needs with expertise in: Custom Forging Solutionsfor superior durability and reliability. Precision Machining and Heat Treatmentfor high-performance components. Special Alloys, Wear-resistant, and Corrosion-resistant Materialsdesigned for tough applications. Metal and Plastic Gears Machining, ensuring high-quality gears that meet your specific requirements in various industries. Non-ferrous Metal, Rubber, and […]

カテゴリーアーカイブ: Study cases and knowledge

Discover industriy trends, case studies, how-to guides, manufacturing processes and FAQs on Welleshaft’s Knowledge Hub—expert insights for engineers and sourcing professionals.

Welleshaft’s Study Cases and Knowledge page addresses key sourcing challenges, quality control hurdles, and real manufacturing pain points—helping buyers make smarter, faster decisions.

High-Precision Aluminum Forging | Expert Forging Solutions for Durable Components Aluminum forging plays a pivotal role in modern manufacturing, providing high-strength, lightweight components used across various industries, from automotive to aerospace. High-precision aluminum forging ensures the reliability and durability of these components, making them a preferred choice over alternative materials. In this article, we will explore the aluminum forging process, its benefits, common defects, and why Welleshaft stands as a trusted global supplier and contract manufacturer for your aluminum forging needs. What is Aluminum Forging? Aluminum forging is a manufacturing process where aluminum is heated and compressed using high-pressure techniques to form strong, durable components. The forging process refines the internal […]

Cutting-Edge Innovations in Smart Manufacturing & Industrial Automation The China International Industry Fair (CIIF) 2024 is set to be a landmark event in the global industrial sector, showcasing cutting-edge technologies and innovations that are shaping the future of manufacturing. This year’s focus is on smart manufacturing, industrial automation, and several other key areas that are driving the modernization of industries around the world. With global participation and industry leaders taking part, CIIF offers a comprehensive platform to explore the latest solutions in technology and manufacturing. Key Trends and Highlights at CIIF 2024 This year’s CIIF emphasizes a wide array of innovations, ranging from industrial automation and robotics to green energy solutions and AI-driven manufacturing. Some of […]

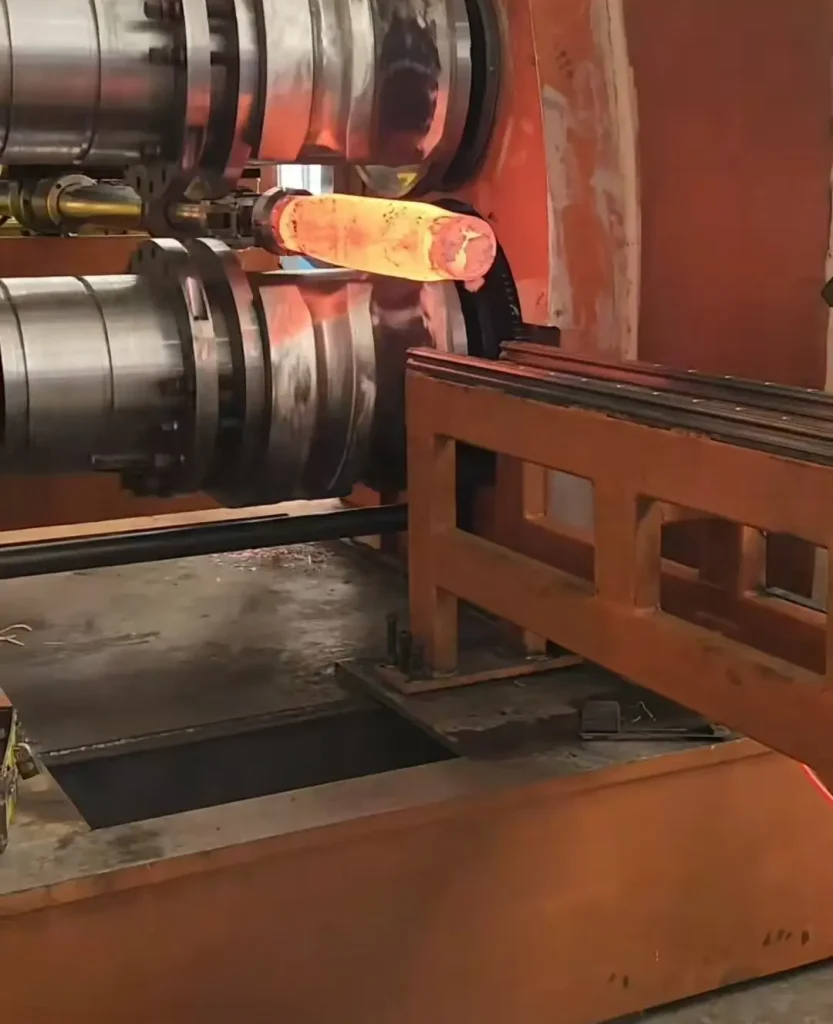

Precision Swaging Services | High-Quality Swaging Solutions for Custom Components Swaging is a vital metal-forming process widely used in industries where precision, durability, and cost-effectiveness are essential. Whether in aerospace, automotive, or medical applications, swaging delivers components that meet the highest standards of accuracy and strength. This article explores swaging in-depth, focusing on its process, tools, and applications. We also recommend Welleshaft, a trusted global supplier and contract manufacturer, for your swaging needs. What Do You Mean by Swaging? Swaging is a metal forming process where a workpiece, typically a rod, tube, or wire, is reshaped using compressive forces applied by a series of dies or hammers. Unlike traditional machining […]

Forging Stainless Steel Components | Precision & Custom Solutions Forging stainless steel components requires a deep understanding of the material’s properties, specialized techniques, and precision to create products that meet diverse industry standards. Stainless steel is highly valued for its strength, corrosion resistance, and aesthetic appeal. In this article, we will explore the process of forging stainless steel, its benefits, and how custom solutions can be achieved through expert craftsmanship. We also highlight Welleshaft, a global supplier known for delivering top-quality stainless steel forging services. Section 1: The Basics of Forging Stainless Steel Stainless steel forging refers to the process of shaping stainless steel by applying compressive forces. This process […]

Expert Copper Forging Services | High-Quality Copper Forged Components Copper forging is a crucial process in the metalworking industry, offering unparalleled strength and durability for a wide range of applications. Whether you’re looking for copper forgings for industrial use, artistic projects, or other specialized applications, understanding the copper forging process, its benefits, and the key players in the market is essential. In this comprehensive guide, we’ll delve into the world of copper forging, provide valuable insights, and recommend Welleshaft as your trusted global supplier and contract manufacturer. Understanding Copper Forging What is Copper Forging? Copper forging is a manufacturing process that involves shaping copper metal through controlled pressure and heat. […]

High-Quality Precision Forging Services | Expert Metal Forging Solutions In the realm of metal manufacturing, precision forging stands out as a pivotal process, delivering high-quality, durable components that meet stringent specifications. This article explores the intricacies of precision forging, including its definition, processes, and benefits, while highlighting Welleshaft as a leading global supplier and contract manufacturer of precision forgings. Understanding Precision Forging What is the Meaning of Precision Forging? Precision forging refers to a specialized forging process designed to produce high-accuracy metal components. Unlike conventional forging, which may involve broader tolerances, precision forging focuses on achieving exact dimensional specifications and superior surface finishes. This process is crucial for applications requiring […]

Medical Grade & Surgical Stainless Steel | Custom SS455 PER ASTM F899 Solutions In the medical and surgical fields, precision, durability, and reliability are paramount. Medical-grade stainless steels, particularly SS455, play a critical role in ensuring that surgical instruments and implants meet the stringent standards set by the healthcare industry. Adhering to ASTM F899 standards, custom stainless steel solutions like SS455 are engineered to withstand the high demands of the medical environment, offering corrosion resistance, biocompatibility, and exceptional strength. This article will explore the unique properties of medical-grade stainless steel, specifically SS455, and highlight Welleshaft as a trusted global supplier and contract manufacturer for custom stainless steel solutions. Section 1: […]

Expert Titanium Forging Services | Precision & Quality in Metal Forging Titanium forging is a specialized process that transforms raw titanium into high-performance components used across various industries. Renowned for its strength, light weight, and resistance to corrosion, titanium is an ideal material for aerospace, medical, and industrial applications. In this article, we’ll explore the intricacies of titanium forging, focusing on the expertise required to deliver precision and quality. We’ll also highlight Welleshaft as a trusted global supplier and contract manufacturer in this domain. Section 1: Understanding Titanium Forging: The Basics Titanium forging involves shaping titanium alloys into components using compressive forces. The process enhances the material’s mechanical properties, making it […]

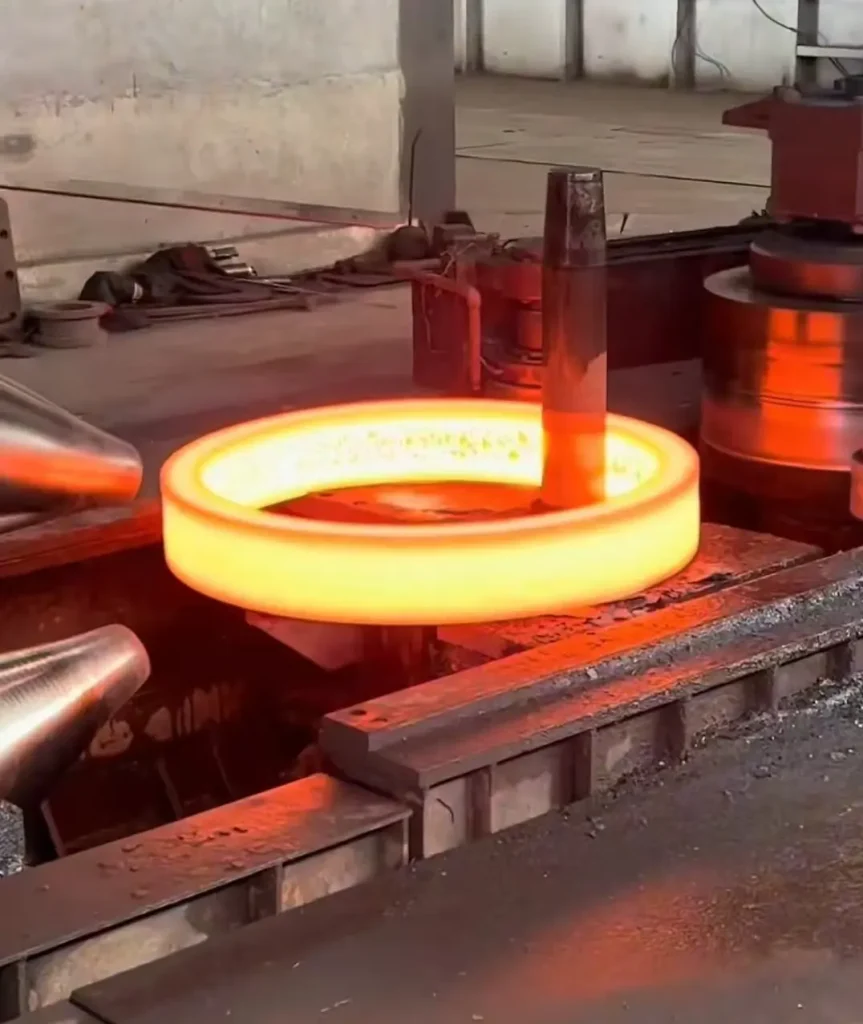

Rill Rolling for Sale: A Comprehensive Guide to Ring Rolling and Rolled Ring Forging Rill rolling might not be a widely recognized term, but it often refers to the detailed and technical aspects of ring rolling and rolled ring forging. These processes are pivotal in creating high-quality metal rings used across various industries. This article provides an in-depth look into these manufacturing techniques, their processes, and considerations for purchasing rolled rings. Section 1: Introduction 1.1. What is Rolled Ring Forging? Rolled ring forging is a manufacturing process used to create high-strength, precision-engineered rings. It involves heating a metal billet to a malleable state and then shaping it into a ring using […]