High-Quality Bronze Forging Services | Expert Bronze Forged Components Bronze forging is a sophisticated process that transforms raw bronze into high-quality, precision-engineered components. This technique is essential for producing durable and reliable parts used in various industries. In this article, we explore the intricacies of bronze forging, including the types of bronze used, the forging process, and why Welleshaft stands out as a trusted global supplier and contract manufacturer for bronze forged components. Section 1:Understanding Bronze Forging What is Bronze Forging? Bronze forging is the process of shaping bronze metal through controlled pressure and heat. This method enhances the metal’s strength, toughness, and durability, making it suitable for applications that […]

カテゴリーアーカイブ: Study Cases

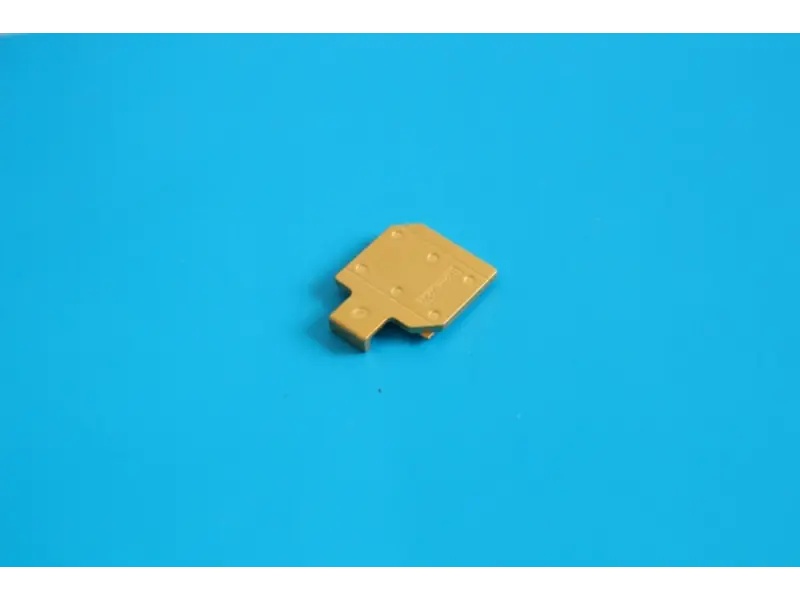

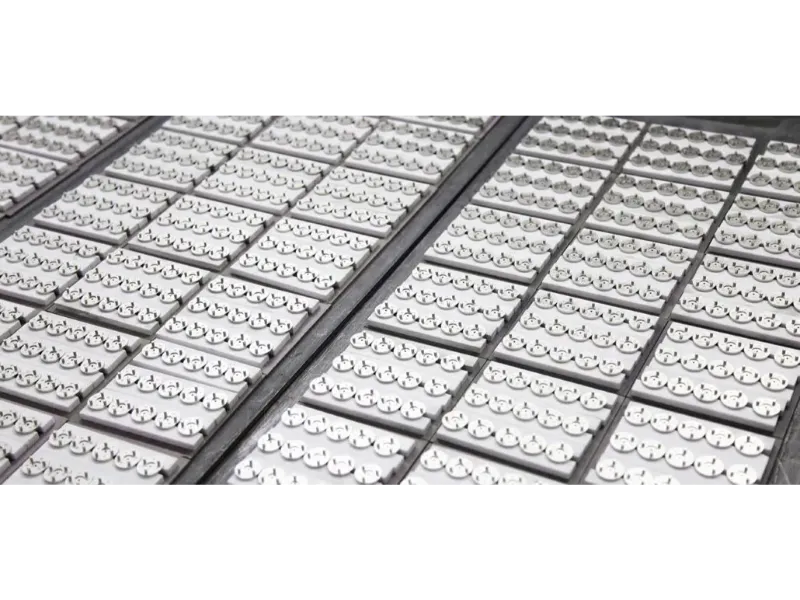

Premium Sintered Copper Components | High-Quality Copper Sintering Solutions When it comes to industrial applications demanding superior performance and reliability, sintered copper components stand out. Known for their durability, versatility, and high conductivity, sintered copper materials are becoming increasingly indispensable in various fields. In this article, we’ll delve into what makes sintered copper a top choice, its advantages, and its diverse applications. We’ll also introduce Welleshaft as a trusted global supplier and contract manufacturer specializing in high-quality sintered copper solutions. Section 1: What is Sintered Copper? Sintered copper refers to copper that has been processed through sintering—a method where copper powder is heated below its melting point to form a […]

Expert Metal Injection Molding Aluminum Services | Precision & Quality Manufacturing In today’s highly competitive manufacturing landscape, finding the right technology and supplier for your metal components is crucial. Metal injection molding (MIM) has emerged as a groundbreaking process for producing high-quality, complex aluminum parts with precision. As industries continue to evolve, the demand for lightweight and durable components has made aluminum a preferred material. Welleshaft, a leader in global manufacturing, offers expert metal injection molding aluminum services, combining precision and quality to meet the exacting demands of various industries. Section 1: What is Metal Injection Molding Aluminum? Metal Injection Molding (MIM) is an advanced manufacturing process that allows for […]

High-Precision Tungsten MIM Solutions | Superior Metal Injection Molding In the world of advanced manufacturing, Metal Injection Molding (MIM) has emerged as a transformative technology, allowing for the production of complex, high-precision components from various metals and alloys. Among these, tungsten stands out for its exceptional properties, making it a prime choice for applications requiring high strength, durability, and resistance to extreme conditions. In this article, we delve into the benefits of Tungsten MIM, its applications, and why partnering with a trusted supplier like Welleshaft can ensure the success of your projects. Section 1: Why Tungsten is Ideal for MIM Tungsten is a refractory metal known for its high melting […]

High-Quality MIM Metal Injection Molding Solutions | Precision & Efficiency Metal Injection Molding (MIM) is a manufacturing process that combines the design flexibility of plastic injection molding with the strength and integrity of powdered metallurgy. This technique is ideal for producing complex and high-precision metal parts. In this article, we will delve into the nuances of Metal Injection Molding, exploring its processes, advantages, and applications. We will also compare it with other metal forming methods, discuss the costs involved, and highlight its role in modern manufacturing. Section 1:Introduction 1.1.What is Metal Injection Molding (MIM)? Metal Injection Molding (MIM) is a process that involves mixing fine metal powders with a binder […]

High-Quality MIM Parts | Precision Manufacturing & Reliable Solutions In the realm of modern manufacturing, Metal Injection Molding (MIM) has become a game-changer, offering high-quality, precision-engineered components for various industries. This article delves into what makes MIM parts stand out, the advantages they offer, and how they compare to other manufacturing methods. Whether you’re looking to understand the difference between forged and MIM parts or exploring the meaning behind MIM, this guide covers it all. Section 1:Introduction 1.1.What is an MIM Part? Metal Injection Molding (MIM) is a sophisticated manufacturing process that combines the best of both powder metallurgy and plastic injection molding. It begins with mixing fine metal powders […]

Nylon Coupling Sleeve: Durable & High-Performance Nylon Couplings In the world of industrial machinery and piping, coupling sleeves play a crucial role in ensuring the efficient transfer of power and motion. Among the various types of coupling sleeves available, nylon coupling sleeves stand out for their durability, high performance, and versatility. This article delves into the characteristics, benefits, and applications of nylon coupling sleeves, addressing key questions and highlighting their significance in various industries. What is a Nylon Sleeve Coupling? A nylon sleeve coupling is a type of flexible coupling that consists of a nylon sleeve connecting two metal hubs. These couplings are designed to transmit torque while accommodating slight […]

Section 1: Introduction to Aluminum Tube Bending Curious about whether aluminum pipe can be bent? You’re not alone! Bending aluminum tubes is a common task in various industries, but it comes with its challenges. In this article, we’ll dive into everything you need to know about bending aluminum pipes, including the best methods, tools, and tips to get the job done right. Section 2: Applications of Bent Aluminum Tubes Bent aluminium pipes have a wide range of applications in industries such as aerospace, marine, and architecture. Custom bent aluminium pipes are used in structures, frameworks, and fluid transportation systems due to their strength and corrosion resistance. The versatility of bent […]

Spline Shafts: Power Transmission and Precision Introduction to Spline Shafts In the realm of mechanical engineering, spline shafts play a pivotal role in transmitting power efficiently across various systems. These shafts are designed with grooves or teeth that mesh with complementary features on mating components, ensuring a secure and precise connection. What are Spline Shafts? Spline shafts are cylindrical mechanical components with ridges or teeth, known as splines, machined along their length. These splines allow for the transmission of torque while permitting axial movement or rotation. Importance in Mechanical Systems Spline shafts are crucial in applications where reliable power transmission and rotational integrity are paramount. They find extensive use in […]

Stub Shaft: Essential Guide to Types, Applications, and Benefits Stub shafts play a crucial role in various mechanical systems, offering reliability and efficiency in transferring torque and power. Understanding the nuances of stub shafts is essential for optimizing machinery performance and ensuring longevity. In this comprehensive guide, we explore everything you need to know about stub shafts, from their types and applications to installation tips and future trends. Introduction to Stub Shaft Stub shafts are short, stout shafts used to transmit torque between components in machinery. They serve as critical linkages in mechanical power transmission systems, facilitating the movement of power from one rotating part to another. Whether in industrial […]

- 1

- 2