The Ultimate Guide to Aluminum Automotive Components Introduction In today’s fast-evolving automotive landscape, aluminum automotive components have emerged as the cornerstone of innovation. From electric vehicles (EVs) to high-performance combustion engines, aluminum plays a crucial role in improving efficiency, reducing emissions, and achieving sustainable manufacturing. This article serves as The Ultimate Guide to Aluminum Automotive Components, offering insights into how this versatile material is transforming the future of mobility. This comprehensive guide explores everything you need to know about aluminum in the automotive industry—from common applications and material benefits to processing methods and supplier selection. Whether you’re an engineer, buyer, procurement specialist, or business owner, this guide will help you […]

月別アーカイブ: 4月 2025

Aluminium Cars: Practical Insights for Automotive Professionals Aluminium cars—once a niche innovation—are now widely adopted in modern vehicle design for their strength-to-weight benefits. For engineers, buyers, and decision-makers in the automotive supply chain, understanding aluminum cars is essential when selecting materials, evaluating designs, or sourcing aluminum automotive components. This article offers Aluminium Cars: Practical Insights for Automotive Professionals, helping you make informed decisions across design, engineering, and procurement. This article answers common questions about aluminium cars, with practical insights and examples to support your sourcing and development decisions. What Are Aluminium Cars? Aluminium cars refer to vehicles that use aluminum extensively in their structural frame, body panels, or key components such […]

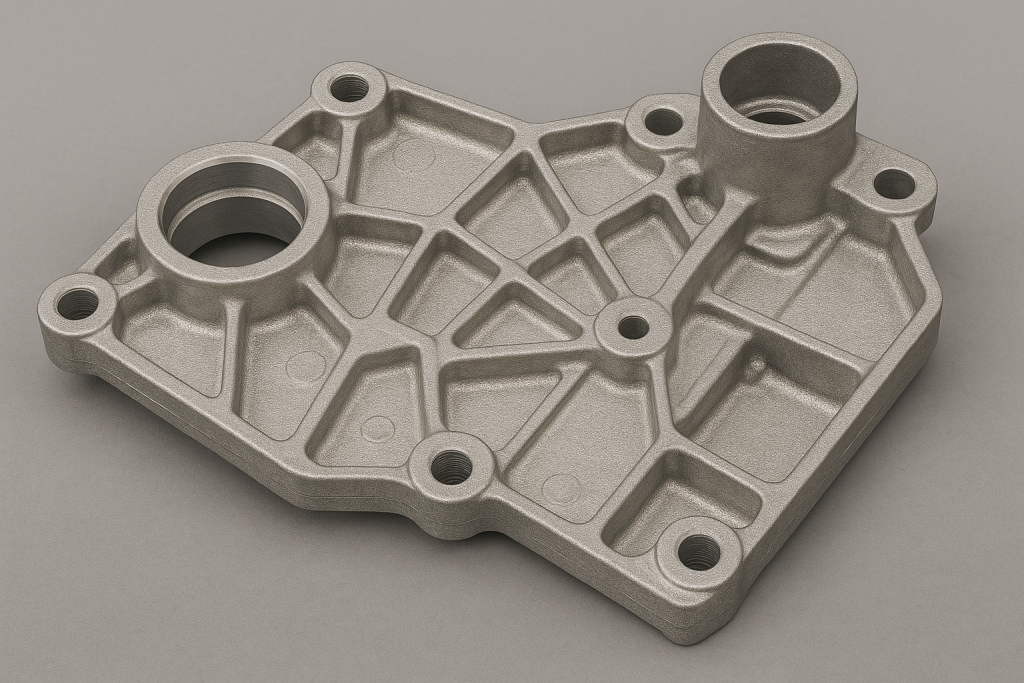

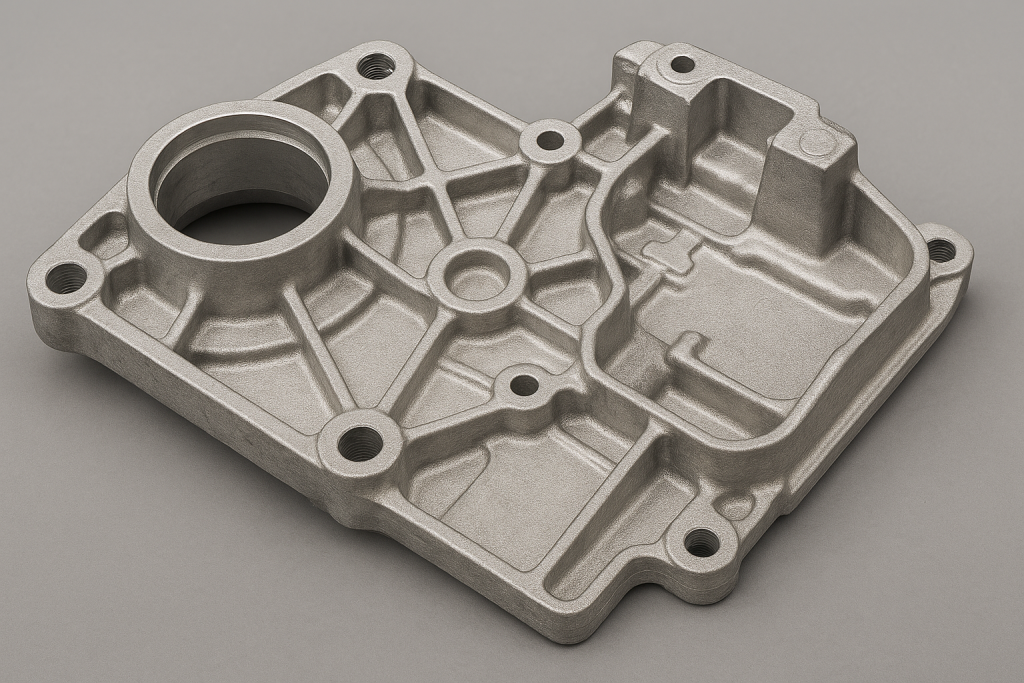

ADC12 vs. Other Alloys: Choosing the Best Alu Cast Metal for Your Application When selecting the right alu cast metal for your die-casting projects, understanding the properties and performance of different alloys is key. ADC12 vs. Other Alloys is a critical comparison to make—ADC12 is a widely used aluminum alloy, but how does it stack up against options like A380, A356, and LM6? This guide will help you choose the ideal aluminum alloy for your specific needs, whether you’re working on automotive parts, electronics, or structural components. 1. Key Properties of ADC12 Aluminum ADC12 aluminum is a popular alu cast metal due to its excellent castability, mechanical properties, and versatility […]

ADC12 Properties: Key Material Insights for Optimal Aluminium ADC12 Applications Aluminium ADC12 is a widely used die-cast aluminum alloy, known for its excellent castability, corrosion resistance, and mechanical strength. The key ADC12 properties—such as high tensile strength, good thermal conductivity, and dimensional stability—make it a preferred choice in automotive, electronics, and industrial applications. In this article, we will explore the key properties of ADC12 aluminum, its mechanical characteristics, industry applications, and why it is the preferred choice for die casting. What is Aluminium ADC12? Aluminium ADC12 is a high-silicon aluminum alloy used in die casting applications. It provides a balance between strength, lightweight properties, and corrosion resistance, making it ideal […]

Introduction When designing durable and high-performance products, selecting the right die cast aluminum material is crucial. Among the various options available, ADC12 aluminum stands out for its excellent castability, mechanical strength, and corrosion resistance. Widely used in automotive, electronics, and industrial applications, ADC12 die casting allows engineers and manufacturers to create complex, lightweight components with superior precision. This article explores the benefits of ADC12 die casting, its applications, and key considerations when choosing a casting supplier to optimize your product design. What is ADC12 Die Casting? Understanding ADC12 Aluminum ADC12 aluminum is a widely used die cast aluminum material, known for its excellent balance of mechanical strength, lightweight properties, and […]

- 1

- 2