Top-Quality Forged Flanges | Durable Solutions for Industrial Applications

Forged flanges play an essential role in connecting pipes, valves, pumps, and other components to form complete piping systems. Their durability, strength, and ability to withstand high pressures make them indispensable in industries such as oil & gas, petrochemicals, power generation, and more. In this article, we will explore the various aspects of forged flanges, including their types, specifications, and manufacturing process. We will also highlight Welleshaft as a trusted global supplier of forged flanges and related components.

Section 1: Forged Steel Flange Types and Specifications

Flanges come in various types, each designed for specific applications and operating conditions. The most common types of forged steel flanges include:

Weld Neck Flange:Engineers use weld neck flanges for high-pressure applications. They feature a long, tapered hub that butt-welds to the pipe, ensuring smooth fluid flow and enhanced mechanical strength.

Slip-On Flange:Installers easily slide slip-on flanges over pipes and weld them inside and outside to increase strength. These flanges suit lower-pressure applications.

Blind Flange:Technicians use blind flanges to close piping system ends. Without a bore, they provide easy access for maintenance and inspection, offering system design flexibility.

Socket Weld Flange:Manufacturers design socket weld flanges for small-diameter, high-pressure pipes. They insert the pipe into a socket and weld it, common in chemical and power industries.

Lap Joint Flange:Workers use lap joint flanges with a stub end where frequent disassembly is needed. They bolt the flange in place without welding.

Threaded Flange:Installers screw threaded flanges onto pipes for low-pressure, non-critical applications. Without welding, they’re ideal for hazardous areas where welding is risky.

Each forged flange must meet specific ASME B16.5 standards that define dimensions, pressure ratings, and materials. Manufacturers produce forged flanges in materials like carbon steel, stainless steel, and alloy steel.

Section 2: The Purpose of Forged Flanges

Forged flanges serve several essential purposes in industrial piping systems:

- Connection: They connect pipes, valves, pumps, and other equipment, enabling easy disassembly for maintenance or inspection.

- Strength: Forging improves the mechanical properties of flanges, making them stronger and more resistant to fatigue, impact, and high-pressure conditions.

- Sealing: Forged flanges provide a tight seal, preventing leaks in high-pressure environments.

- Corrosion Resistance: Stainless steel and alloy flanges offer resistance to corrosion, making them suitable for harsh environments such as offshore platforms and chemical plants.

Section 3: Leaders in Forged Flanges for Piping Systems

As a leading manufacturer of forged flanges, Albero a pozzo provides durable and high-quality solutions for various industrial applications. Our forged flanges are designed to meet international standards such as ASME B16.5, ensuring compatibility and safety in critical operations.

Welleshaft’s expertise lies in producing:

- Stainless Steel Flanges: Offering excellent corrosion resistance, ideal for offshore, marine, and chemical industries.

- Carbon Steel Flanges: Known for their strength and durability, carbon steel flanges are widely used in oil & gas and power generation.

- Alloy Steel Flanges: These flanges provide additional mechanical strength and heat resistance, suitable for high-temperature applications.

- Nickel Alloys:Used in specialized environments where high corrosion resistance is required.

Welleshaft stands out as a reliable partner for companies around the globe, particularly in China, India, and other key industrial regions. Whether you need standard flanges or custom solutions, we have the manufacturing capabilities to meet your needs.

Section 4: ASME B16.5 Forged Flanges: Stainless and Carbon Steel

ASME B16.5 is the standard that governs pipe flanges and fittings in the sizes ranging from NPS 1/2 through NPS 24. It covers pressure-temperature ratings, materials, dimensions, tolerances, and marking.

Stainless steel forged flanges are widely used in industries where corrosion resistance is crucial, while carbon steel flanges are chosen for their strength and cost-effectiveness. Welleshaft manufactures both types, adhering to ASME B16.5 standards, ensuring they meet all industry regulations.

4.1. Forged Flanges vs Plate Flanges

One common question is: What is the difference between forged flanges and plate flanges?

Forged Flanges: These are made by forging steel, which involves heating and shaping the metal to improve its grain structure, resulting in enhanced strength, toughness, and durability.

Plate Flanges: These are cut from a steel plate and do not undergo the forging process. As a result, they are less robust and have lower mechanical properties compared to forged flanges. Plate flanges are generally used in lower-pressure applications.

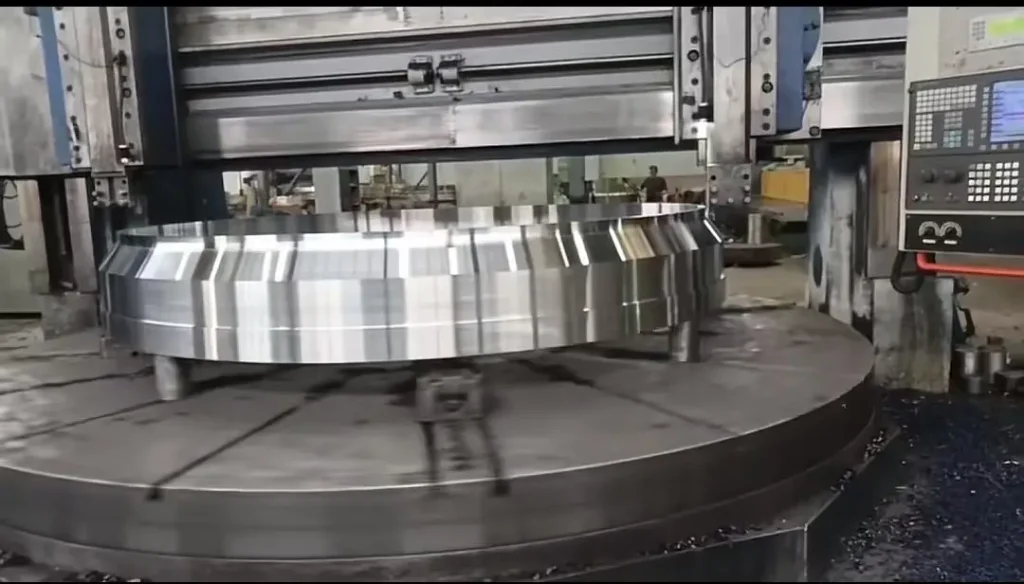

4.2. The Forged Flanges Manufacturing Process

Forging is a process that improves the mechanical properties of metal by compressing it under high pressure. The process for manufacturing forged flanges includes several key steps:

Heating the Metal:We heat the metal to a specific temperature based on the material to make it malleable.

Forging:We place the heated metal between dies and compress it to form the flange shape.

Trimming:We trim off excess material to achieve the correct dimensions.

Heat Treatment:We perform heat treatment on the forged flange to enhance its strength and toughness.

Machining:Finally, we machine the flange to precise tolerances to meet industry standards.

4.3. Slip-On Flange vs Weld Neck Flange

Slip-on flanges are easier to install and more cost-effective, making them a popular choice for low-pressure applications. However, weld neck flanges are preferred for high-pressure systems due to their strong, welded connection to the pipe, providing greater structural integrity.

Section 5: Stainless Steel Flange Supplier in China

Welleshaft is a leading stainless steel flange supplier in China, offering a range of products for both domestic and international markets. We are recognized for our high-quality materials, precision manufacturing, and adherence to global standards such as ASME B16.5.

Section 6: Forged Flanges Price and Weight Chart

When selecting forged flanges for industrial applications, it’s essential to consider both their weight and price, as these factors vary based on the flange type, size, material, and pressure class. The cost of a forged flange depends largely on the manufacturing process, material composition (such as stainless steel or carbon steel), and the specific standards they meet, like ASME B16.5.

6.1.Price Factors of Forged Flanges:

- Material: Stainless steel flanges tend to be more expensive due to their corrosion resistance and longer lifespan compared to carbon steel flanges.

- Size: Larger flanges require more material and involve more intricate manufacturing processes, making them more expensive.

- Pressure Class: Flanges with higher pressure ratings (such as Class 150, Class 300, or higher) are built to withstand more demanding environments, which increases their cost.

- Quantity: Bulk orders typically reduce the price per unit, making large-scale projects more cost-efficient.

- Customization: Custom-designed flanges or those requiring specific machining features can have a higher price due to additional labor and tooling needs.

6.2.Weight Chart for Common Forged Flange Types:

The weight of a forged flange is an important consideration, as it impacts shipping, handling, and installation logistics. Below is a general weight chart for common flange types based on a selection of sizes.

| Flange Type | Nominal Size (inches) | Pressure Class | Weight (kg) |

| Weld Neck Flange | 2 | Class 150 | 5.5 |

| Slip-On Flange | 4 | Class 300 | 12.7 |

| Blind Flange | 6 | Class 150 | 15.3 |

| Socket Weld Flange | 8 | Class 600 | 25.4 |

| Lap Joint Flange | 10 | Class 300 | 30.7 |

| Threaded Flange | 12 | Class 150 | 45.8 |

Note: This is a simplified weight chart for reference. Actual weights may vary based on the manufacturer, specific standards, and custom modifications.

6.3.Typical Price Ranges:

- Carbon Steel Flanges: $5 – $500 depending on size and class.

- Stainless Steel Flanges: $10 – $800 for higher corrosion resistance.

- Alloy Steel Flanges: $20 – $1000 for high-strength, heat-resistant applications.

To get an accurate price quote for your specific needs, it’s recommended to consult directly with suppliers like Albero a pozzo, who can offer competitive pricing based on your project’s requirements.

Welleshaft provides a comprehensive weight chart and pricing details for forged flanges, ensuring that clients select the right products for their projects. Whether you’re looking for ASME B16.5 standard flanges or custom solutions, Welleshaft has the resources to provide the highest quality flanges at competitive prices.

Section 7: Why Choose Welleshaft?

With years of experience and advanced manufacturing capabilities, Albero a pozzo is your go-to supplier for forged flanges and fittings. We offer:

- Custom solutions to meet specific client needs.

- A broad selection of flange types, including weld neck, blind, and slip-on flanges.

- Products that adhere to strict international standards such as ASME B16.5.

- Competitive pricing and reliable global shipping.

Welleshaft is committed to delivering top-quality forged flanges that exceed your expectations in terms of performance and durability. Partner with us for all your forged flange needs, and ensure the success of your projects with reliable and durable products.