1.Military Investment Castings | Precision Defense Castings by Welleshaft

Welleshaft has earned its place among ISO-certified Defense Castings manufacturers, trusted for delivering reliable, precision-built components used in mission-critical military and defense operations. With over six decades of hands-on experience supporting defense contractors, we build custom investment casting for military parts from a wide selection of advanced alloys. Our team knows the strict demands these systems face, and we craft casting solutions that meet or exceed tough defense standards.

2.Why Choose Welleshaft for Defense Castings

Albero a pozzo provides precision defense castings crafted to handle the harsh realities of military service. Our components are traceable down to the raw material and conform to strict U.S. and international standards. We also guide our clients through how to source defense castings internationally, selecting metals and methods that match each unique need.

(1)Our Competitive Edge:

ITAR-registered, FFL-licensed foundry

All tooling and machining done in-house

Documentation and traceability aligned with MIL-SPEC

Skilled in engineering complex cast geometries

Handles small batches and full-scale production

Over 60 years of casting craftsmanship

As one of the best foundries for defense-grade components, Welleshaft supplies both primary and secondary defense contractors worldwide.

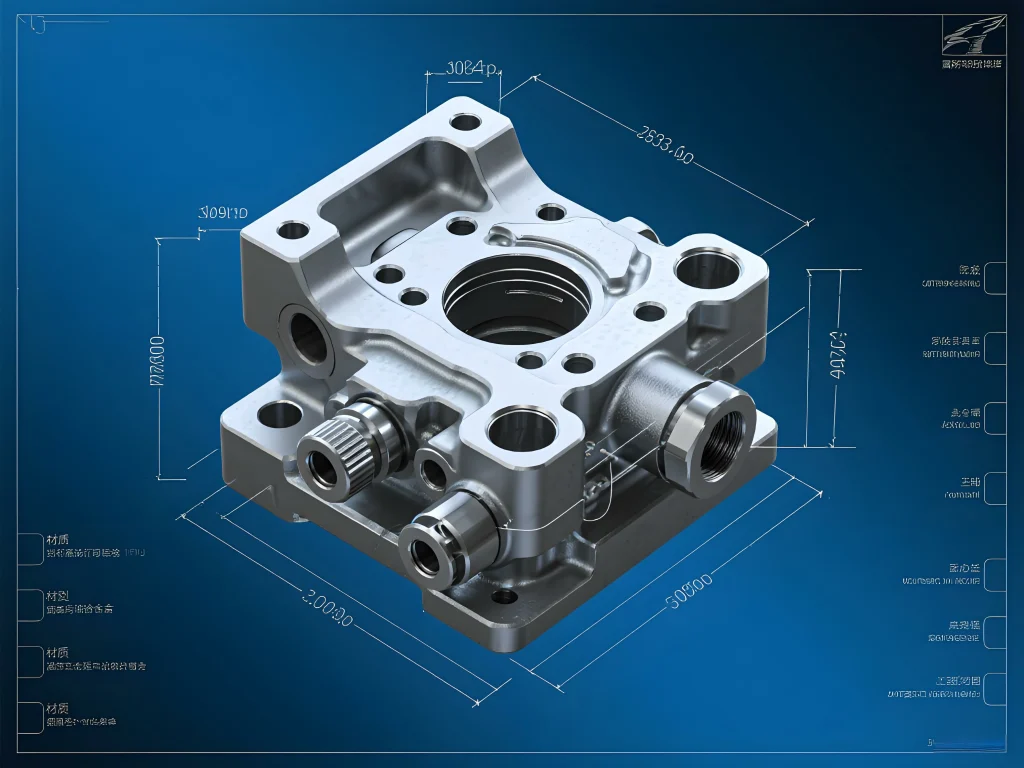

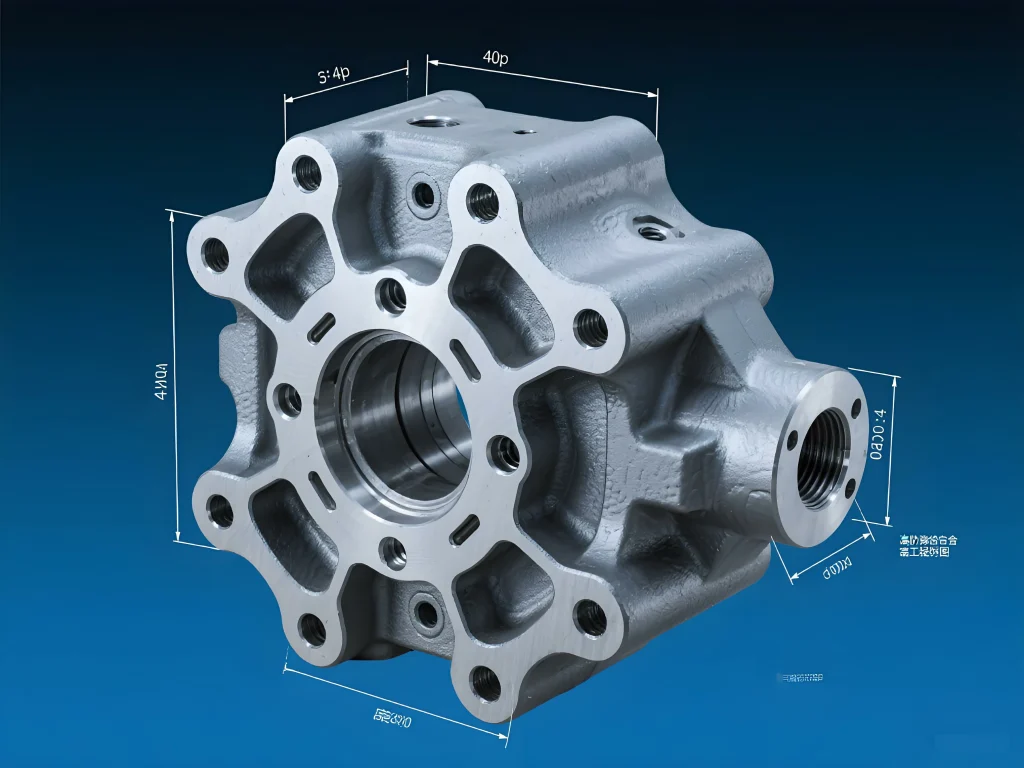

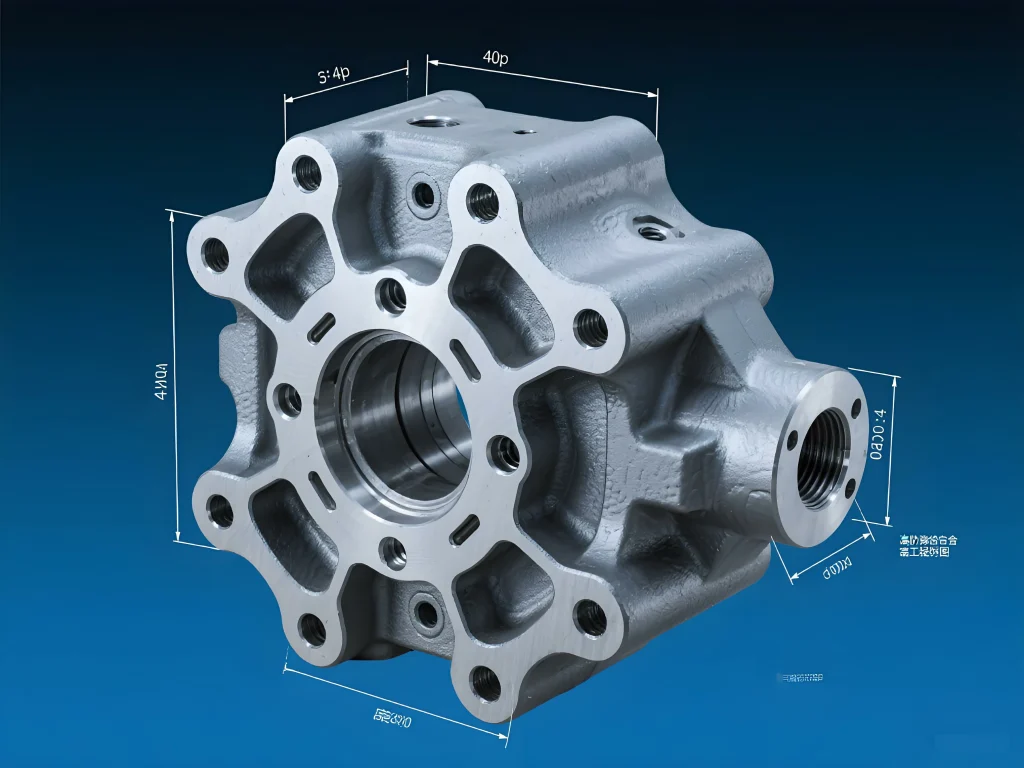

3.Types of Military & Defense Castings We Produce

We’ve delivered thousands of defense castings for systems that see action on teh field, in the sky, and at sea. Each part is built to meet real-world military expectations.

(1)Defense Casting Solutions We Offer:

Aerospace-grade investment castings for defense systems

Turbine blade castings for aircraft engines used in defense applications

Precision cast components for missile systems and guidance modules

Stainless steel castings for drones and aerial platforms in defense

High-temperature alloy castings for engines exposed to thermal stress

Castings for armored vehicle components and assemblies

Heavy-duty castings for tanks and APCs operating in rough terrain

Military gear housing investment castings designed for compact setups

Cast armor components for battlefield vehicles and protective shielding

From CAD modeling through final dimensional checks, we handle every step in-house to deliver high-tolerance castings for critical military applications.

4.Common Alloys Used in Defense Castings

We rely on proven metal alloys that hold up under extreme pressure, heat, and wear. Choosing the right material ensures your casting performs as it should — every time.

Most Requested Alloys:

| Material Type | Example Uses |

| Stainless Steel | Stainless steel castings for defense drones, mounts, and sensor housings |

| Cobalt-Based Alloys | High-temperature alloy castings for defense engines, gas turbine support |

| Nickel-Based Metals |

Missile components, aerospace-grade investment castings for military airframes |

| Steel (Carbon & Alloy) |

Castings for armored vehicle components, heavy-duty castings for tanks and APCs |

| Aluminum | Military gear housing investment casting, panels, and light fixtures |

5.Key Benefits of Welleshaft’s Defense Casting Capabilities

We don’t just pour metal — we deliver battle-ready results.

(1)What Makes Us Reliable:

Engineering support with CAD, mold flow tools, and real testing

Build all patterns and molds on-site — zero outsourcing

Controlled casting processes for clean, consistent parts

Volume-ready custom investment casting for military parts

Post-processing in-house: heat treat, NDT, and surface prep

6.Applications of Defense Investment Castings

We build parts that stand up to battle conditions and extreme missions. These castings show up in:

Electronic housings for guidance systems

Missile and UAV components that fly far and stay reliable

Injection seat parts and escape mechanisms

Receivers for sonar and radar systems on ships and drones

Microwave horns and elbows for communications

Firearm and artillery components built for recoil and pressure

Shipboard mechanical assemblies built for salt, shock, and wear

7.People Also Ask

1.What materials are best for military castings?

Stainless steel, cobalt alloys, and nickel-based metals are the go-to picks for custom investment casting for military parts. They hold up to heat, impact, and corrosive elements.

2.What are aerospace-grade investment castings used for?

These castings are used in aircraft that face tough mechanical and thermal loads. They’re usually made from cobalt or nickel alloys and built to tight tolerances.

3.Can Welleshaft produce turbine blade castings for military aircraft?

Absolutely. We’ve built turbine blade castings for military aircraft using heat-resistant alloys, with geometry tailored for airflow and stress.

4.How is the quality of military castings tested?

Every casting goes through visual checks, dimensional inspection, and NDT like x-ray or ultrasonic testing. No shortcuts.

5.Is Welleshaft ITAR certified?

Yep, we are fully registered with ITAR and follow U.S. defense manufacturing controls.

8.Contact Welleshaft for Military-Grade Defense Castings

If you’re a military buyer or contractor needing defense castings built to last, Welleshaft is ready to support your next build. As a leading ISO-certified defense casting manufacturer, we take pride in delivering quality that holds up under fire.

Call us now or reach out online to talk about precision defense castings and custom investment casting for military parts.