Impacting Blow Bars: Durable Crusher Parts for Effective Size Reduction

Section 1:Introduction

In the realm of material processing, efficient size reduction is paramount. Impact crushers, with their powerful blows, play a crucial role in achieving this goal. At the heart of these machines lie impacting blow bars, the workhorses that deliver the crushing force. These robust components are subjected to immense stress and wear and tear, making their durability and performance critical for optimal crushing operations.

Section 2:Understanding Impacting Blow Bars

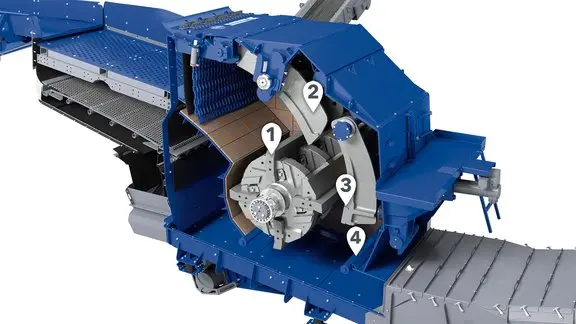

Impacting blow bars, also known as crusher hammers or impact plates, are integral components of impact crushers. These machines utilize the principle of kinetic energy to break down materials. As the rotor spins at high speeds, the blow bars strike the incoming material, causing it to fracture into smaller pieces. The material is then thrown against the impact wall or other surfaces within the crusher chamber, further reducing its size.

Section 3:Factors Influencing Blow Bar Performance and Durability

Several factors significantly influence the performance and longevity of impacting blow bars:

Material Composition: The choice of material is crucial. High-strength alloys, such as those containing high chromium or manganese, are commonly used to withstand the abrasive forces and impact loads encountered during crushing operations.

Design and Geometry: The shape and size of the blow bar can affect its impact force, wear resistance, and overall efficiency.

Operating Conditions: Factors like the type of material being crushed, the feed size, and the operating speed of the crusher all influence the wear rate of the blow bars.

Maintenance Practices: Regular inspection, maintenance, and timely replacement of worn-out blow bars are essential to ensure optimal crusher performance and minimize downtime.

Section 4:Benefits of Durable Impacting Blow Bars

Investing in high-quality, durable impacting blow bars offers several significant advantages:

Increased Productivity:

Durable blow bars minimize downtime due to frequent replacements, leading to increased production output.

Reduced Operating Costs:

By extending the service life of blow bars, you can reduce maintenance costs and overall operating expenses.

Improved Product Quality:

Consistent and effective crushing action results in more uniform product size distribution, enhancing the quality of the final product.

Enhanced Safety:

Durable blow bars reduce the risk of unexpected failures, improving the safety of the crushing operation.

Section 5:Choosing the Right Impacting Blow Bars

Selecting the appropriate impacting blow bars requires careful consideration of several factors:

Material Compatibility: The chosen material should be compatible with the type of material being crushed to minimize wear and tear.

Application Requirements: The specific application, such as primary or secondary crushing, will dictate the required impact force and wear resistance.

Crusher Type: Different types of impact crushers, such as horizontal shaft impact crushers (HSI) and vertical shaft impact crushers (VSI), may require specific blow bar designs.

Manufacturer Reputation: Choosing a reputable manufacturer ensures the quality and reliability of the blow bars.

Section 6:Welleshaft: A Trusted Global Supplier and Contract Manufacturer

Welleshaft has established itself as a leading global supplier and contract manufacturer of high-quality impacting blow bars. With a strong focus on innovation and customer satisfaction, Welleshaft offers a wide range of products tailored to meet the diverse needs of the crushing industry.

Section 7:Key Features of Welleshaft Impacting Blow Bars:

7.1 Superior Durability: Manufactured from high-quality materials using advanced manufacturing techniques, Welleshaft blow bars are designed to withstand the harshest operating conditions.

7.2 Customized Solutions: Welleshaft offers customized solutions to meet specific customer requirements, ensuring optimal performance and longevity.

7.3 Global Reach: With a global presence, Welleshaft provides prompt and reliable service to customers worldwide.

7.4 Commitment to Quality: Welleshaft adheres to strict quality control standards to ensure the highest level of product quality and customer satisfaction.

By partnering with Welleshaft, you can ensure that your crushing operation is equipped with the most durable and efficient impacting blow bars, maximizing productivity and minimizing downtime.

Conclusion

Impacting blow bars are critical components of impact crushers, playing a vital role in achieving effective size reduction. By investing in high-quality, durable blow bars, you can enhance the efficiency, productivity, and safety of your crushing operation. Welleshaft, with its expertise in manufacturing high-performance impacting blow bars, is your trusted partner in optimizing your crushing process.