How Much Weight Can an Unistrut Trolley Hold? | Comprehensive Guide

Unistrut trolleys are versatile and essential components in many industrial and construction applications. Knowing how much weight can an Unistrut trolley hold is crucial for maximizing their utility and ensuring safety. In this comprehensive guide, we will explore various aspects of Unistrut trolleys, including their weight capacity, types, applications, and more.

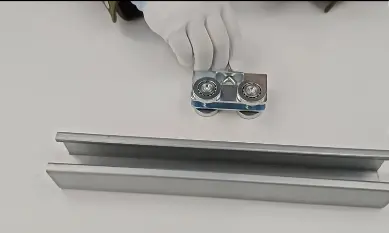

What is a Unistrut Trolley?

A Unistrut trolley is a movable assembly that runs along a Unistrut channel, providing support and mobility for various loads. If you’re wondering how much weight can an Unistrut trolley hold, it’s important to consider the specific model and application. These trolleys are commonly used in industrial settings to transport heavy items along a predefined path.

Manufacturing and Materials of Components of a Unistrut Trolley

The performance and durability of Unistrut trolleys heavily depend on the quality of their components. When considering how much weight can an Unistrut trolley hold, understanding the manufacturing processes and materials used can help you select the right trolley for your specific needs.

Manufacturing Processes

Casting: Many Unistrut trolley components, such as wheels and rollers, are manufactured through casting processes. This involves pouring molten metal into molds to create precise shapes.

Machining: Technicians use precision machining to cut, drill, and shape metal parts, ensuring components meet exact specifications.

Stamping: Manufacturers press metal sheets into desired shapes using high-pressure machinery to produce parts like brackets and mounting plates.

Welding: Welders assemble various components of the Unistrut trolley, creating strong and durable connections.

Finishing: The production team coats or galvanizes components to protect against corrosion and enhance durability, using techniques like powder coating, painting, and galvanizing.

Materials Used

Steel: Manufacturers use steel—the most common material—for Unistrut trolleys because of its strength and durability. They often use it for main structural components like the frame and wheels.

- Carbon Steel:Used for its high strength and durability, making it suitable for heavy-duty applications.

- Stainless Steel: Offers excellent corrosion resistance, making it ideal for environments where rust and corrosion are concerns.

Aluminum: Manufacturers choose aluminum for its lightweight properties and corrosion resistance, making it ideal for applications where reducing weight is important.

Plastic: Producers use high-strength plastics for certain components, like rollers, to reduce friction and wear.

Rubber: Designers incorporate rubber in parts that need flexibility and cushioning, such as specific wheels and bumpers.

Zinc: Steel components often receive a zinc coating through galvanizing to provide extra corrosion resistance.

Key Components and Their Materials

Unistrut Trolley Wheels:

Material: Steel, Aluminum, or Plastic

Manufacturing: Casting or Machining

Unistrut Trolley Rollers:

Material: Steel or Plastic

Manufacturing: Machining or Molding

Strut Channel:

Material: Steel (often galvanized) or Aluminum

Manufacturing: Roll Forming and Stamping

Mounting Brackets and Plates:

Material: Steel or Aluminum

Manufacturing: Stamping and Machining

Bearings:

Material: Steel or Ceramic

Manufacturing: Precision Machining

Quality Control in Manufacturing

Quality control is essential in the manufacturing of Unistrut trolley components to ensure they meet the required standards and specifications. This includes:

- Material Testing:Ensuring the raw materials meet the necessary quality standards.

- Dimensional Inspection: Verifying the dimensions of the components to ensure they fit correctly and function properly.

- Load Testing: Testing the components to ensure they can withstand the specified loads.

- Corrosion Testing:Ensuring components, especially those used in corrosive environments, have adequate protection.

How Much Weight Can a Unistrut Trolley Hold?

The weight capacity of a Unistrut trolley is influenced by several factors. Understanding these factors is essential for selecting the appropriate trolley for your needs and ensuring safe and efficient operation.

1. Trolley Type

Standard vs. Heavy-Duty:

- Standard Unistrut Trolleys:Typically designed for lighter loads, standard trolleys are suitable for general-purpose applications. They have lower weight capacities compared to heavy-duty versions.

- Heavy-Duty Unistrut Trolleys:Built for rigorous use, heavy-duty trolleys can support significantly higher weights. They are ideal for industrial applications where heavy loads are common.

2. Material Quality

Steel:

- Carbon Steel:Known for its high strength and durability, carbon steel is commonly used in heavy-duty trolleys. It can handle substantial weights but may require protection against corrosion.

- Stainless Steel:Offers excellent resistance to corrosion, making it ideal for environments exposed to moisture or chemicals. Stainless steel trolleys are robust and have high weight capacities.

Aluminum:

- Lightweight and Corrosion-Resistant:Aluminum trolleys are lightweight and resist corrosion but may have lower weight capacities compared to steel. They are suitable for applications where weight reduction is crucial.

3. Channel Type

Strut Channel Size and Strength:

- The size and strength of the strut channel significantly affect the trolley’s weight capacity. Larger and thicker channels can support more weight.

- Galvanized or Coated Channels:Channels that are galvanized or coated can resist corrosion, ensuring longevity and maintaining structural integrity over time.

4. Roller and Wheel Quality

Material and Design:

- Steel Rollers:Provide high strength and durability, suitable for heavy loads.

- Plastic or Nylon Rollers:Reduce friction and wear, ideal for lighter loads.

- Precision Bearings:High-quality bearings ensure smooth operation and can handle higher loads efficiently.

5. Assembly and Installation

Correct Assembly:

- Proper assembly of the trolley components ensures that the load is evenly distributed, preventing undue stress on any single part.

Secure Installation:

- Ensuring that the strut channel is securely mounted and the trolley is correctly installed is crucial for maintaining its weight capacity. Improper installation can lead to reduced load-bearing capacity and potential failure.

6. Load Distribution

Even Distribution of Weight:

- The weight should be evenly distributed across the trolley to prevent overloading one side or component. Uneven loads can reduce the effective weight capacity and cause premature wear or failure.

7. Environmental Factors

Operating Environment:

- Environmental conditions such as temperature, humidity, and exposure to chemicals can affect the materials and performance of the trolley.

- Corrosive Environments:Require trolleys made from or coated with corrosion-resistant materials to maintain their load-bearing capabilities.

8. Frequency and Type of Use

Regular vs. Occasional Use:

- Trolleys used frequently or for continuous operations may require higher durability and maintenance compared to those used occasionally.

- Dynamic vs. Static Loads:Trolleys carrying moving loads (dynamic) may have different weight capacities compared to those carrying stationary loads (static).

9. Safety Margins

Built-in Safety Margins:

- Manufacturers often include safety margins in the weight capacity ratings to account for unexpected loads or conditions. It’s essential to consider these margins when selecting a trolley.

10. Manufacturer Specifications

Adherence to Guidelines:

- Always follow the manufacturer’s specifications and guidelines for load capacities and installation procedures. These are based on rigorous testing and ensure safe and optimal performance.

Typical Weight Capacities

Unistrut trolleys, also known as Unistrut carriers or roller trolleys, are used in various applications including conveyor systems, suspension systems, and support structures. The weight capacity of these trolleys can vary based on their design, size, and the materials used. Here are typical weight capacities for common types of Unistrut trolleys:

Light-Duty Unistrut Trolleys:

Capacity: Up to 500 pounds (227 kg)

Applications: Suitable for light-duty applications where less weight is involved, such as small support structures or light conveyor systems.

Medium-Duty Unistrut Trolleys:

Capacity: Approximately 1,000 to 2,000 pounds (454 to 907 kg)

Applications: Used for more demanding tasks, including moderate conveyor systems, and overhead support structures.

Heavy-Duty Unistrut Trolleys:

Capacity: Up to 5,000 pounds (2,268 kg) or more

Applications: Designed for heavy-duty applications such as large industrial conveyors, heavy machinery support, or large-scale structural support systems.

Specialized or Custom Trolleys:

Capacity: Can exceed 5,000 pounds (2,268 kg), depending on customization and specific requirements.

Applications: Tailored for unique applications or extreme load conditions, often involving custom engineering.

Applications of Unistrut Trolleys

Unistrut trolleys are versatile components used in various industrial and commercial applications due to their flexibility and ability to handle a range of weights and loads. Here are some common applications:

Conveyor Systems:

Material Handling: Unistrut trolleys are often used in conveyor systems to move products or materials along a production line. They support the movement of goods and can be integrated into both overhead and floor-mounted conveyor systems.

Packaging and Sorting: Trolleys in conveyor systems are utilized for sorting and packaging operations, enabling smooth and efficient movement of products through different stages.

Suspension Systems:

Overhead Support: Trolleys can be used to support and suspend various equipment, such as lighting systems, ductwork, or piping, from overhead tracks. This application is common in warehouses, factories, and commercial buildings.

HVAC Systems: Unistrut trolleys support HVAC ductwork and piping, allowing for adjustment and maintenance of these systems.

Rail Systems:

Moveable Rail Supports: Trolleys are used in rail systems to create adjustable or moveable supports for various structures. This application is useful in settings where equipment or components need to be repositioned frequently.

Custom Racking Systems:

Adjustable Racks: In warehouses and storage areas, Unistrut trolleys can be part of custom racking systems that allow for adjustable and modular storage solutions. They enable easy reconfiguration of storage layouts.

Automated Systems:

Automated Guided Vehicles (AGVs): Trolleys can be integrated into automated systems to support AGVs or automated material handling equipment, facilitating the movement of goods without manual intervention.

Workstations and Assembly Lines:

Modular Workstations: Unistrut trolleys are used in the construction of modular workstations and assembly lines, allowing for easy adjustments and reconfigurations to meet changing production needs.

Workbenches: They can be used to create mobile workbenches or tool storage solutions that can be repositioned as needed.

Structural Support:

Building Frameworks: Trolleys can be part of structural frameworks in buildings, providing support for various structural elements and allowing for adjustments as required.

Maintenance and Service Applications:

Access Platforms: Trolleys can be used in access platforms and maintenance systems to provide movable platforms for servicing equipment or performing inspections.

Safety and Security Systems:

Barrier Systems: In safety and security applications, trolleys can support movable barriers or screens that can be repositioned as needed for access control or safety measures.

Unistrut Trolley Accessories

Unistrut trolleys can be complemented with various accessories to enhance their functionality, ensure compatibility, and improve performance. Here’s a list of common Unistrut trolley accessories:

Track and Rail Systems:

Unistrut Channels: The main support structure for trolleys, available in different sizes and profiles (e.g., U-channel, C-channel).

Rails: Tracks that trolleys move along, available in various materials and profiles to match the trolley design.

Mounting Brackets and Hardware:

Trolley Mounting Brackets: Attach trolleys to channels or rails securely.

End Stops: Prevent trolleys from sliding off the ends of the track.

Bracket Clamps: Securely hold brackets in place on Unistrut channels.

Adjustable Supports:

Height Adjusters: Allow for vertical adjustments of the trolley system to accommodate different heights or clearances.

Swivel Casters: Provide mobility and adjustability for trolleys, allowing for easy movement in various directions.

Rollers and Wheels:

Replacement Wheels: Spare or replacement wheels for trolleys to ensure smooth operation and load-bearing.

Guide Rollers: Help maintain alignment and reduce wear on the track and trolley.

Hangers and Mounting Hardware:

Suspension Hangers: For hanging trolleys from overhead structures or support systems.

Mounting Plates: Secure trolleys or related equipment to surfaces or supports.

End Caps and Covers:

Track End Caps: Cover the ends of tracks to prevent debris from entering and to provide a finished look.

Cover Plates: Protect the trolley and track from dust, debris, and other environmental factors.

Safety Accessories:

Guard Rails: Provide safety barriers to prevent accidental contact with moving trolleys.

Warning Labels: Indicate potential hazards and ensure safe operation of the trolley system.

Alignment and Adjustment Tools:

Alignment Jigs: Help ensure proper alignment of trolleys on the track for smooth operation.

Adjustment Tools: Facilitate the fine-tuning of trolleys and track systems to ensure optimal performance.

Custom Mounting Solutions:

Custom Brackets: Tailored to fit specific trolley and track configurations or applications.

Adapters: Enable compatibility with various Unistrut channel sizes and types.

Lubrication and Maintenance Products:

Lubricants: To keep wheels and rollers moving smoothly and to reduce wear.

Cleaning Products: For maintaining the cleanliness and functionality of the trolley system.

These accessories enhance the functionality, safety, and versatility of Unistrut trolleys, ensuring that they meet the specific needs of various applications.

Why Choose Welleshaft?

Welleshaft is a trusted global supplier and contract manufacturer of high-quality Unistrut trolleys. With a commitment to excellence and a wide range of products, Welleshaft is your go-to source for all your Unistrut trolley needs.

1. Expertise and Experience

Established Reputation: Welleshaft has over 13 years of experience in the industry, specializing in custom aluminum casting and bending aluminum tube components.

Technical Knowledge: Extensive expertise in manufacturing high-quality components ensures that products meet precise specifications and industry standards.

2. Custom Solutions

Tailored Manufacturing: Welleshaft offers customized solutions for a wide range of industrial needs, including bespoke designs and specifications.

Flexible Production: Capable of accommodating unique requirements and adapting to various project demands.

3. Quality and Precision

High Standards: Commitment to high-quality standards and rigorous testing processes ensures reliability and durability of products.

Precision Engineering: Utilizes advanced technology and techniques to produce components with exceptional accuracy.

4. Comprehensive Product Range

Diverse Offerings: Provides a broad range of products, including aluminum casting parts, coupling sleeves, ACME threaded rods, and more.

Innovative Solutions: Continuously expands product offerings to include the latest advancements in material and design.

5. Global Reach

International Service: Capable of serving clients worldwide, with a strong presence in markets such as Singapore and China.

Efficient Logistics: Proven track record of managing international orders and deliveries effectively.

6. Customer-Centric Approach

Personalized Support: Dedicated customer service team that offers expert advice and support throughout the project lifecycle.

Responsive Communication: Prompt and clear communication to address client needs and inquiries.

7. Competitive Pricing

Cost-Effective Solutions: Offers high-quality products at competitive prices, providing value for money.

Transparent Pricing: Clear and upfront pricing with no hidden costs.

8. Commitment to Innovation

Research and Development: Invests in R&D to stay at the forefront of industry trends and technological advancements.

Continuous Improvement: Regularly updates processes and products to enhance performance and meet evolving customer needs.

9. Sustainability and Responsibility

Eco-Friendly Practices: Adopts sustainable practices in manufacturing processes to reduce environmental impact.

Ethical Operations: Committed to ethical business practices and social responsibility.

10. Proven Track Record

Successful Projects: Demonstrated success with numerous projects across various industries, showcasing reliability and performance.

Satisfied Clients: Positive feedback and long-term relationships with clients highlight the company’s reputation for excellence.

Conclusion

Understanding the weight capacity and features of Unistrut trolleys is essential for their safe and efficient use. Whether for industrial applications or DIY projects, Unistrut trolleys offer versatility and reliability. For top-quality Unistrut trolleys and expert support, choose Welleshaft as your trusted global supplier and contract manufacturer.