Hollow Shafts: Characteristics, Advantages, and Applications

A hollow shaft is a cylindrical component with a central void, designed to transmit torque and rotational motion. Unlike solid shafts, which are entirely filled, hollow shafts feature an empty core, offering unique benefits in various industrial applications. This article explores the characteristics, advantages, and diverse uses of hollow shafts in modern engineering.

Characteristics of Hollow Shafts

Hollow shafts are characterized by their cylindrical shape with an internal void, which distinguishes them from solid shafts. This void reduces weight without compromising strength, making them ideal for applications where weight reduction is critical. Typically made from metals like steel, aluminum, or titanium, hollow shafts are engineered to withstand high torque and rotational forces.

Advantages of Hollow Shafts

1. Weight Reduction:

Hollow shafts are significantly lighter than solid shafts of similar dimensions. This weight reduction contributes to overall system efficiency, especially in applications where minimizing mass is essential, such as aerospace and automotive industries.

2. Enhanced Dynamics:

The internal void of hollow shafts allows for improved dynamic characteristics, including reduced inertia and better torsional stiffness-to-mass ratio. This translates to smoother operation, reduced vibrations, and enhanced precision in motion control systems.

3. Versatility in Design:

Engineers can exploit the internal space of hollow shafts for various purposes, such as housing wiring, cooling mechanisms, or additional components. This versatility enhances the functionality of the shaft within complex machinery and equipment.

4. Cost Efficiency:

Despite initial material costs, hollow shafts can offer long-term cost savings due to reduced energy consumption (from lower inertia), simplified assembly (lighter components), and decreased maintenance needs.

Applications of Hollow Shafts

Hollow shafts find application across numerous industries, including:

Electrical Motors: Used in electric motors to transmit torque while accommodating wiring or cooling channels.

Gearboxes: Integral in gearbox assemblies where weight reduction and design flexibility are crucial.

Automation Systems: Employed in robotics, CNC machines, and automation equipment for precise motion control.

Aerospace: Vital in aircraft systems for reducing overall weight and enhancing fuel efficiency.

Medical Devices: Utilized in medical robotics and imaging systems for compact yet powerful design solutions.

Hollow Shaft vs. Solid Shaft: Key Differences

Weight: Hollow shafts are lighter, offering potential weight savings.

Design Flexibility: Hollow shafts allow for internal components or mechanisms, enhancing versatility.

Cost: Initial material costs may be higher, but operational savings can offset this over time.

Conclusion

In conclusion, hollow shafts represent a significant advancement in engineering design, offering substantial benefits over traditional solid shafts. From weight reduction and enhanced dynamics to versatile applications across industries, hollow shafts continue to play a pivotal role in modern machinery and equipment. As technology advances, further innovations in material science and manufacturing processes will likely expand the capabilities and applications of hollow shafts even further.

For manufacturers and engineers seeking optimal performance and efficiency, integrating hollow shafts into designs can lead to superior outcomes in terms of functionality, cost-effectiveness, and overall system performance.

Please contact us using below information if you have any RFQ’s or questions about hollow shaft.

Email:[email protected]

Phone:+86 15650179596(whatsapp/wechat)

Frequently Asked Questions About Hollow Shafts

1. What is the purpose of a hollow shaft?

A hollow shaft serves several purposes in engineering applications. Its primary function is to transmit torque and rotational motion between components while reducing overall weight compared to solid shafts. Additionally, the internal void of a hollow shaft can accommodate wiring, cooling mechanisms, or other components, enhancing its versatility in various industrial settings.

2. How does a hollow shaft compare to a solid shaft?

Hollow shafts differ from solid shafts primarily in their design and weight characteristics. While solid shafts are completely filled, hollow shafts feature an internal void, making them lighter. This weight reduction is advantageous in applications where minimizing mass is critical, such as aerospace, automotive, and robotics industries. Hollow shafts also offer flexibility in design, allowing for the integration of additional components or functionalities within the shaft itself.

3. What are the advantages of using a hollow shaft over a solid shaft?

The advantages of using a hollow shaft include:

Weight Reduction: Hollow shafts are lighter, which can lead to overall system weight savings.

Enhanced Dynamics: They offer improved torsional stiffness-to-mass ratio and reduced inertia, resulting in smoother operation and better control.

Versatility: The internal void can be utilized for various purposes, such as housing wiring or cooling channels, enhancing design flexibility.

Cost Efficiency: Despite potentially higher material costs, hollow shafts can offer long-term savings through reduced energy consumption and maintenance needs.

4. What industries commonly use hollow shafts?

Hollow shafts are prevalent in industries requiring lightweight yet robust components for efficient operation. Common applications include:

Electrical Motors: Where hollow shafts accommodate wiring and cooling mechanisms.

Gearboxes: For weight reduction and design flexibility.

Automation and Robotics: In precision motion control systems.

Aerospace: For reducing aircraft weight and improving fuel efficiency.

Medical Devices: In compact yet powerful equipment designs.

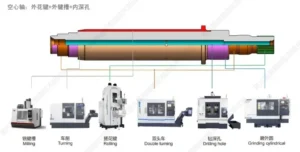

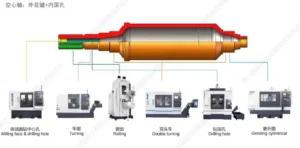

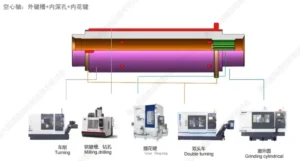

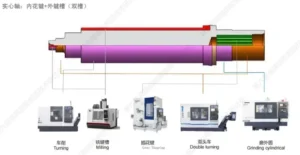

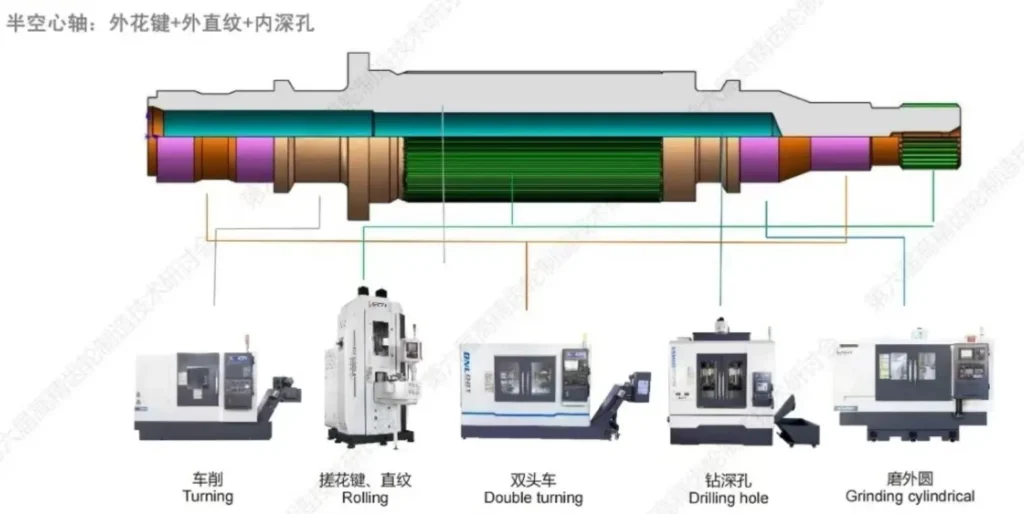

5. How are hollow shafts manufactured?

Hollow shafts are typically manufactured using processes such as machining, forging, or extrusion, depending on the material and design requirements. These processes involve shaping the material into a cylindrical form with an internal void, ensuring structural integrity and dimensional accuracy. Advanced manufacturing techniques may also include additive manufacturing (3D printing) for complex geometries or specialized applications.