Gear Builder is state-of-the-art software designed to facilitate the creation and manufacture of gears. This software saves time, makes fewer mistakes, and is cost-effective for businesses. This article will cover Gear Builder, its benefits, its use in the industry, how to get started, and the future of gear-building technology.

Section 1: What is Gear Builder?

Gear Builder is a very complex tool for designing and manufacturing gears, including state-of-the-art computational algorithms with CAD/CAM integration. Mechanical engineers, manufacturers, and designers are constantly seeking a single platform to embody everything that will make the process of building gears both automatic and optimised. This huge functionality range makes up a set of tools that includes:

- Design Automation: Using it can quickly generate complex geometries in gears.

- Simulation and Analysis: It can be used to test and validate designs of gears under different conditions.

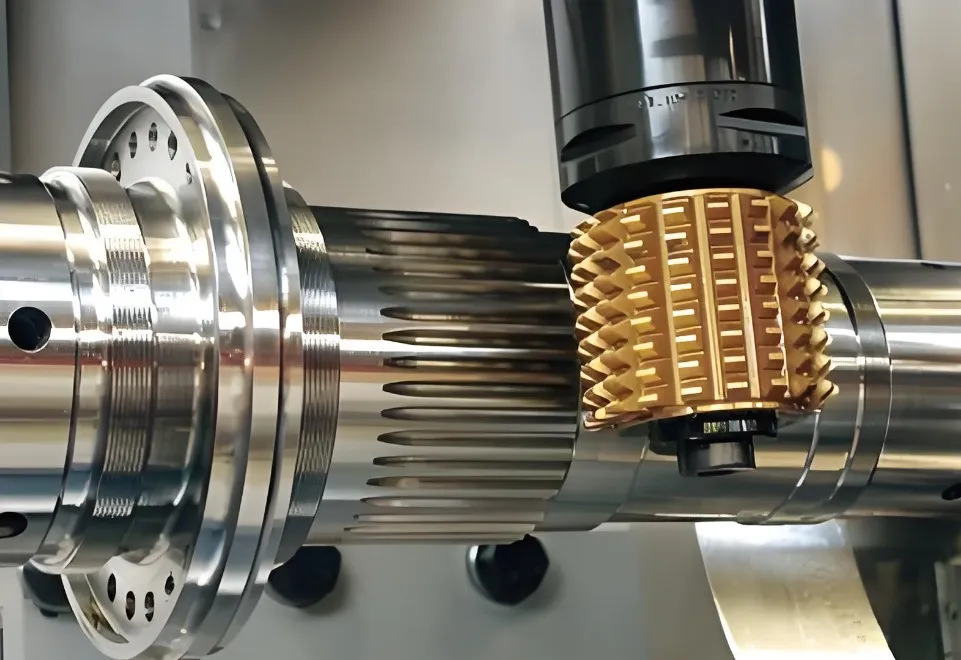

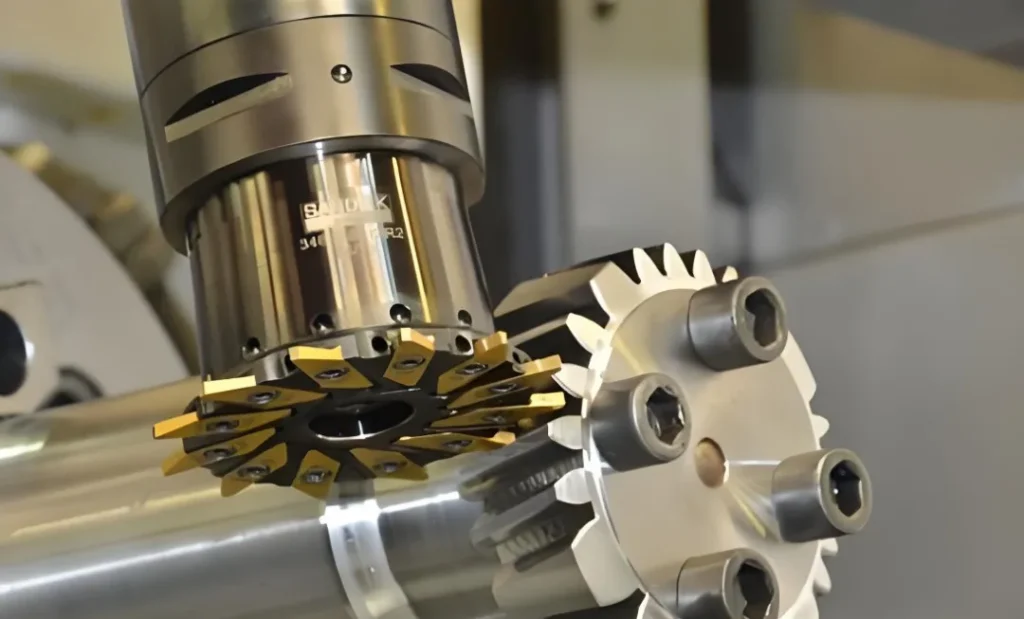

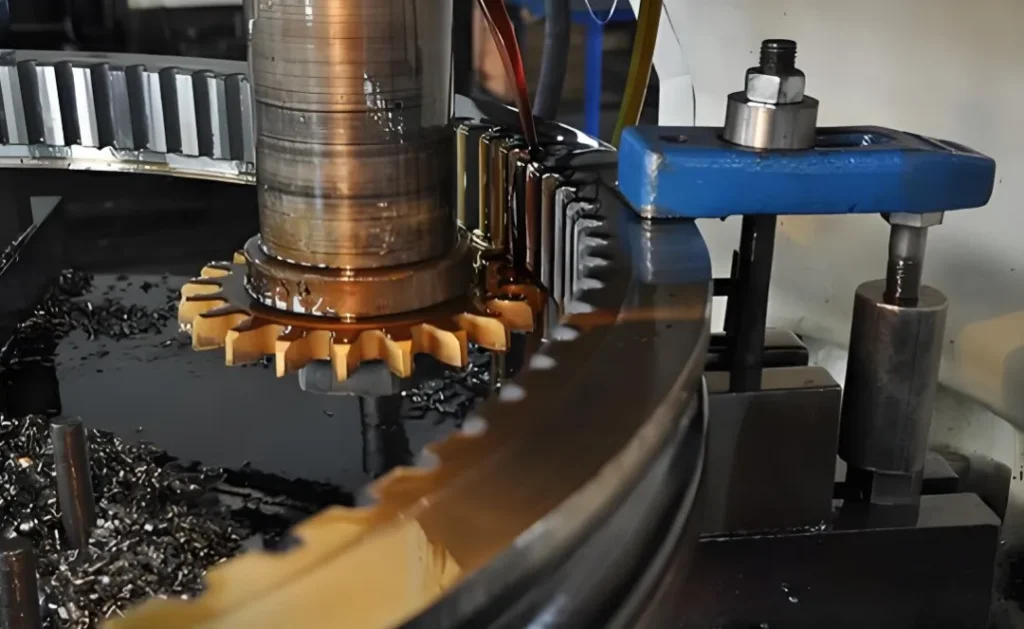

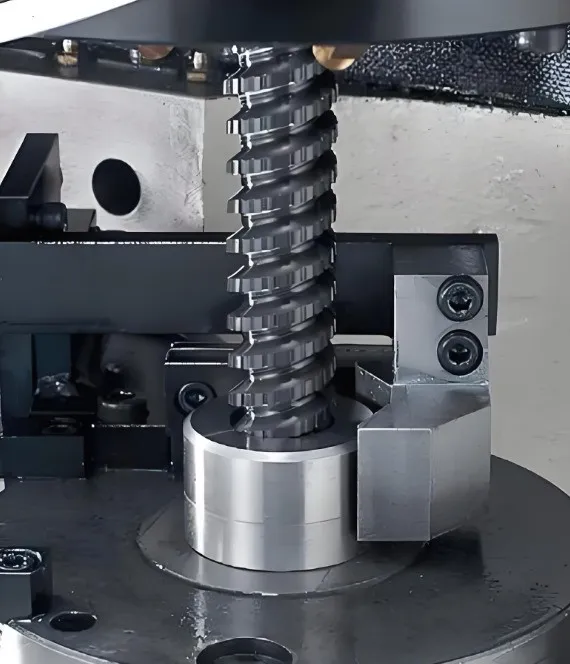

- Manufacturing Integration: It provides integration with CNC machines to produce gears precisely.

- Customisation: Customisation has a lot of flexibility per specific industries’ requirements.

Section 2: Benefits of Gear Builder

Gear Builder adoption offers mechanical engineering operations a host of benefits. Some of the main advantages are:

1. Greater Efficiency

Gear Builder allows a high degree of automation in some of the drudgery associated with gear design and manufacturing. This greatly reduces time from the concept phase to production, allowing faster turnarounds for any project.

2. Higher Accuracy

Using advanced algorithms and simulation tools, Gear Builder optimizes any gears design for performance and durability. This accuracy minimizes the propensity for errors and increases the reliability of the final product.

3. Cost-Effectiveness

The time and resources saved from manual design and testing translate into cost savings. Added to that would be the cost efficiency of material usage and manufacture processes brought about by Gear Builder’s capability of optimizing them.

4. Versatility

The Gear Builder works for any configuration: spur, helical, bevel, and worm gears. Its versatility makes the software applicable in the most varied industries.

5. Better Collaboration

The intuitive interface and the possibility of integrations make the platform easier for collaboration. Thus, it allows engineers, designers, and manufacturers to work harmoniously during the project cycle to ensure everything is in place.

Section 3: How Different Industries Use Gear Builder

From versatility to advanced features, Gear Builder finds applications in many industries. Here are examples of how other sectors make use of this technology:

Automobile Industry

Accurate and reliability are the two ingredients that go into making the automotive sector. The gearbox builder designs and manufactures gears for transmissions, differentials, and many other critical applications. Simulation of actual world scenarios in this industry assures that the gears meet rather strict performance and durability criteria.

Aerospace Industry

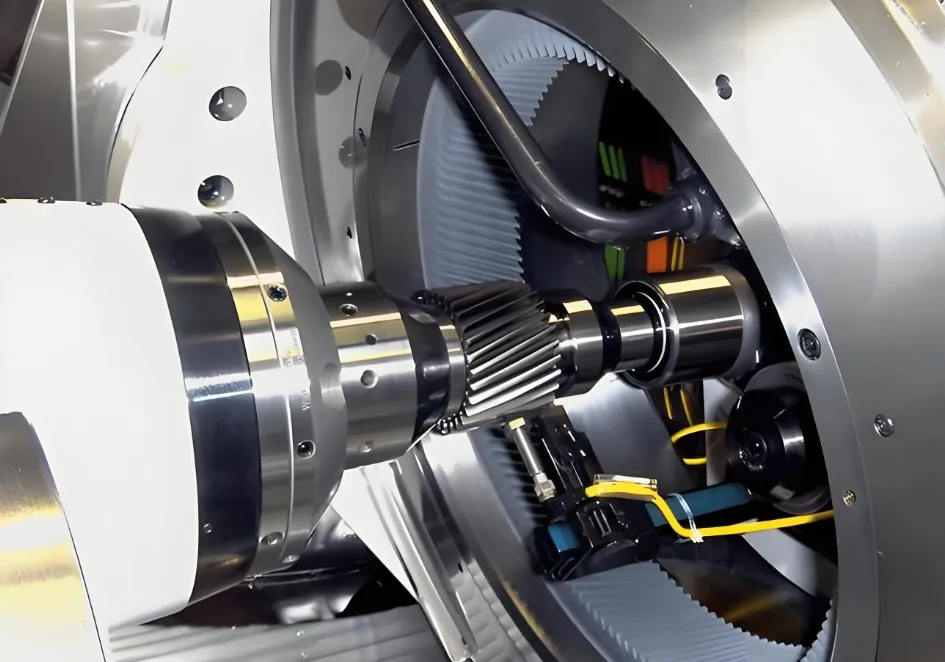

The aerospace industry requires high-performance and conditioning gears. Gear Builder helps engineers design lightweight, high-strength gears for aircraft engines and landing gear systems, among many other major aerospace applications.

Manufacturing Industry

Different manufacturers producing various products also utilise Gear Builder to attain optimum production. From machinery and equipment to consumer merchandise, the tool helps make gears that will extend the effectiveness and service life of manufacturing systems.

Robotics

Gears are crucial for precision in robotics since they are responsible for motion control. A gear Builder creates custom gears based on the specifications of robotic systems so that they can provide smooth, precise movement.

Renewable Energy

Contemporary wind turbines and other renewable energy converters are equipped with extreme and efficient gears. The Gear Builder aids in designing gears that would offer the maximum energy conversion efficiency with minimum maintenance, directly impacting the sustainability of a renewable energy plant.

Section 4: Getting Started with Gear Builder

Putting Gear Builder into practice is painless. Follow these steps to get started:

1. Need Assessment

Identify what problems your projects have to solve and how Gear Builder does this. From there, specify the kind of gears you wish to design and how many you will need to fabricate.

2. Choosing the Right Plan

The software is available in various plans to fit different business sizes and needs. Choose the option that best aligns with your business goals and budget.

3. Onboarding and Training

Full training and support are provided to ensure you’re well-equipped to use the tool to its fullest potential. Take advantage of this opportunity to maximize the platform’s benefits.

4. Integrations

Integrate your gear design software with existing CAD/CAM systems and CNC machines. This vital integration enables seamless design-to-production workflows.

5. Start Designing

Design gears using an intuitive interface and advanced capabilities. Then, run simulations to ensure your designs perform successfully and are fully optimized.

Section 5: The Future of Gear-Building Technology

Gear-building technology has been an ever-evolving process. Advancing in materials science, computational algorithms, and new manufacturing techniques are taking it further. Here are some trends and developments to watch for:

1. AI and Machine Learning

Including Artificial Intelligence and Machine Learning in gear-building software will further enhance the predictive capability of Simulation for optimisation.

2. Advanced Materials

New material developments, including high-performance composites and alloys, further enable the production of light, strong, and durable gears.

3. Additive Manufacturing

Additive manufacturing, also known as 3D printing, will revolutionise gear manufacturing by enabling complex geometries impossible to achieve using traditional methods.

4. IoT Integration

This will be pretty useful in increasing efficiency and life with the IoT which will, in turn, provide real-time monitoring and maintenance of gear systems.

5. Sustainability

In a nutshell, modern gear design and manufacturing have revolutionized linearization processes. Some of the key advantages include increased productivity, improved accuracy, cost savings, greater flexibility, and enhanced team collaboration. These benefits are evident across various industries such as automotive, aerospace, manufacturing, robotics, and renewable energy. With advanced tools at your fingertips, you can complete projects more quickly, achieve better output quality, and reduce overall costs.

Ready to revolutionise mechanical engineering with Gear Builder? Let us help you understand how Gear Builder can help you with your gear manufacturing. To learn more about the future of gear-building technology, Visit our website or contact our sales team.

FAQs

- How can Gear Builder help my business?

It saves time, reduces costs, and improves gear production accuracy, making it easier to collaborate.

- Who is using Gear Builder?

Industries such as automotive, aerospace, manufacturing, robotics, and renewable energy use it extensively.

- How do I get started with Gear Builder?

Identify your needs, choose a plan, get trained, integrate systems, and start designing.

- Will Gear Builder be able to customise according to my needs?

Yes, it can be customised to any industry requirement.