1.Why Mechanical Processing Quality Control Matters

In today’s manufacturing supply chain, inspection services are essential for ensuring product reliability, compliance, and cost efficiency. Whether you are exporting CNC parts, producing automotive components, or manufacturing custom machinery, choosing the right inspection company impacts both quality and profit margins.

At WelleShaft, we specialize in mechanical processing inspection solutions tailored for global exporters, backed by ISO 9001-certified systems and advanced inspection equipment.

2.What is Mechanical Processing Inspection Services?

Inspection services involve verifying dimensional accuracy, material integrity, and surface quality after machining, grinding, forging, or welding operations. This process helps identify common defects, such as scratches, burrs, incorrect tolerances, and assembly misalignments. Our inspection checklist for factories ensures every part meets ISO standards and customer specifications, reducing returns and protecting your reputation.

3.How Mechanical Processing Quality Inspection Works

The quality inspection process includes:

| Step | Inspection Method | Purpose |

| 1. Visual Inspection | Surface check | Detect visible defects |

| 2. Dimensional Measurement | Calipers, CMM | Verify tolerances |

| 3. Functional Testing | Fit & performance check | Ensure operability |

| 4. Non-Destructive Testing (NDT) | Ultrasonic, dye penetrant | Identify hidden flaws |

By following this structured workflow, WelleShaft ensures consistent quality across high-volume and custom production runs.

4.Benefits of Using an Inspection Company

Hiring a professional mechanical processing inspection company like Welle Inspection offers measurable benefits:

Cost Reduction: Early defect detection lowers scrap rates.

Compliance: Meets ISO 9001, ASTM, and customer-specific standards.

Faster Shipments: We provide same-day reporting for urgent orders.

Global Coverage: Our inspection teams operate in China, Southeast Asia, and Europe.

5.ISO Standards for Quality Inspection

International ISO standards for mechanical processing quality inspection ensure that production meets global compliance. At WelleShaft, our inspectors are trained to ISO 9001 and ISO/IEC 17020 standards.

We also help clients meet automotive, aerospace, and industrial machinery requirements through tailored inspection solutions for manufacturing industry.

6.Applications Across Industries

Mechanical processing inspection solutions are crucial for:

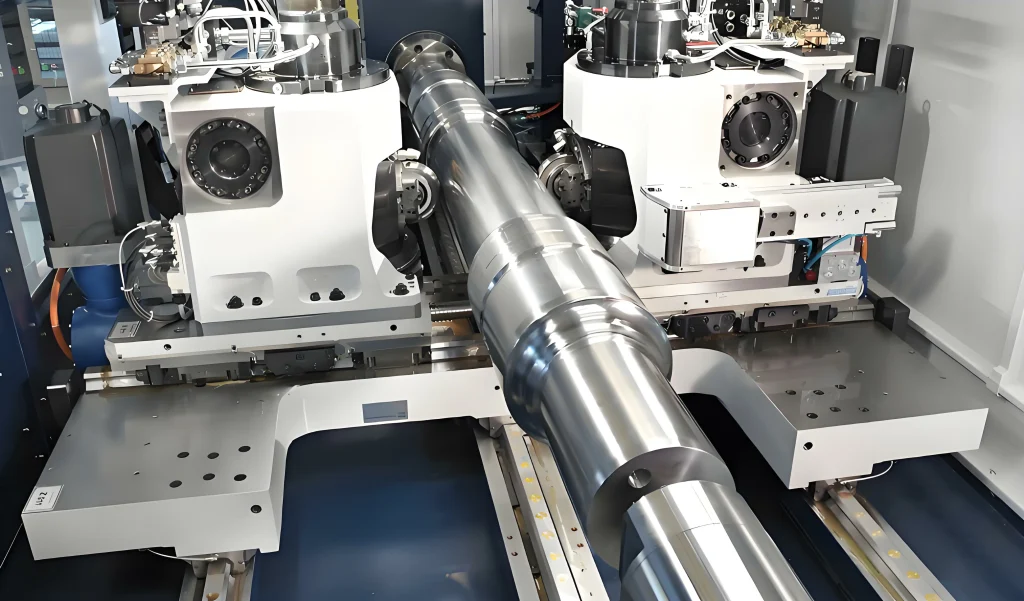

Automotive parts suppliers – Precision in gears, shafts, and engine parts.

Metal parts manufacturing – Dimensional control for CNC machining.

Custom components – One-off projects requiring tight tolerances.

Export shipments – Pre-shipment inspections for overseas buyers.

7.Customer Case Study

A German automotive supplier faced urgent export shipment deadlines with risk of rejection. WelleShaft’s mechanical processing inspection services detected out-of-spec parts before shipping, saving €75,000 in potential returns. Our same-day reporting allowed the client to rework defective items without missing delivery schedules.

9.Why Choose WelleShaft for Inspection

Over 10 years of industry experience in mechanical processing quality inspection.

Certified inspectors with ISO 9001 and NDT Level II credentials.

Advanced equipment: CMMs, laser measurement, ultrasonic testers.

Transparent pricing with no hidden costs.

Proven track record with exporters in 30+ countries.

10.FAQ: Mechanical Processing Inspection

(1)How much does mechanical processing quality inspection cost?

Depends on complexity, volume, and location; request a free quote.

(2)Can inspection detect hidden defects?

Yes, through non-destructive testing (NDT) methods like ultrasonic and dye penetrant.

(3)Which industries need these services?

Automotive, machinery, energy, and custom manufacturing.

(4)Why is inspection important before shipping?

Prevents costly returns and ensures compliance with buyer specifications.

Written by the engineering team at WelleShaft, with over a decade of experience in mechanical processing quality control and third-party inspection. Our certified inspectors have worked on projects across automotive, industrial machinery, and precision metal parts industries.