Metal Injection Molding Manufacturer: Choosing the Right Supplier for Quality and Compliance What Are MIM Parts and Why Are They Important? Metal Injection Moulding (MIM) parts are small to medium-sized metal components produced by metal injection moulding companies using fine metal powders combined with injection molding. Unlike traditional machining or casting, MIM enables complex shapes, […]

Monthly Archives: novembre 2025

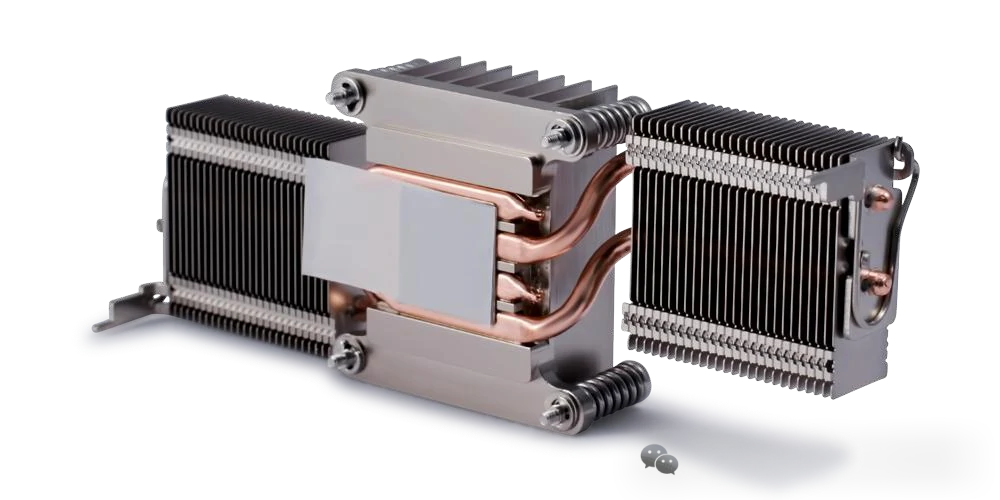

What is a Skived Fin Heat Sink? High-Performance Skived Fin Heat Sinks are high-performance thermal solutions designed to maximize heat dissipation in compact electronics. Unlike standard heat sinks, High-Performance Skived Fin Heat Sinks feature precision-cut fins from a single metal block, providing superior thermal conductivity and structural integrity.Engineers often ask, “What is a Skived Fin […]

Which Metal Injection Molding Machines and MIM Equipment Are Best for High-Precision MIM Molding? What Are MIM Machines and What Types Exist? What Are MIM Machines? Metal Injection Molding Machines for Metals, or MIM machines, shape powdered metals mixed with polymer binders into precise parts via mim molding. Unlike traditional machining, which removes material, MIM […]

Metal Injection Molding Parts: MIM Casting & Machining What is Metal Injection Molding Parts? Metal Injection Molding(MIM) parts are high-precision metal parts made using the metal injection molding process, ideal for complex geometries, thin walls, and high-volume production. Using MIM steel, mim aluminum, and injection molded titanium, this micro metal injection molding technique outperforms traditional machining of metal parts, […]

MIM Materials | What Types of Metals Can Be Used in MIM? What Is Metal Injection Molding (MIM)? Metal Injection Molding (MIM), also called metal injection moulding or powder injection moulding (PMIM), produces small, complex metal parts with high precision. Engineers mix metal powders with binders, inject them, then debind and sinter the parts using […]

MIM Process Explained: From Defect Control to Process Optimization What Is MIM? Metal Injection Molding(MIM) — also known as metal injection moulding — is an advanced manufacturing method that merges powder metallurgy with plastic injection molding. By injecting fine metal powders mixed with polymer binders into precision molds, MIM allows for mass production of complex metal parts with tight tolerances […]

How Can USA & Germany Manufacturers Avoid Costly Worm Gear Defects? | Welleshaft Ensuring top-quality worm gear manufacturing is critical for industrial, automotive, and heavy-duty applications. Defective worm gears can cause costly production delays, equipment failures, and brand reputation loss. At Welleshaft, we specialize in precision worm gear manufacturing, custom worm gear inspection, and high-precision worm […]

Casting Alloys Manufacturing Optimization: How to Reduce Defects in China for USA & Germany Clients In today’s competitive casting alloys manufacturing market, overseas buyers demand high-quality, reliable production. Many industrial casting alloys manufacturers face challenges like high scrap rates, inconsistent mechanical properties, and delayed deliveries. In automotive casting alloys manufacturing and precision casting alloys manufacturing, compliance with ASTM […]

Aluminum fasteners have become essential in industries where weight reduction, strength, and corrosion resistance are critical — from automotive and marine to aerospace and precision machinery. However, not all aluminum alloys perform equally. The most widely used grades — 2024, 6061, and 7075 — each offer distinct mechanical, chemical, and economic properties that influence fastener […]

-materials-welleshaft.webp)