1.Why Zinc Die Casting Stands Out for Durable Parts

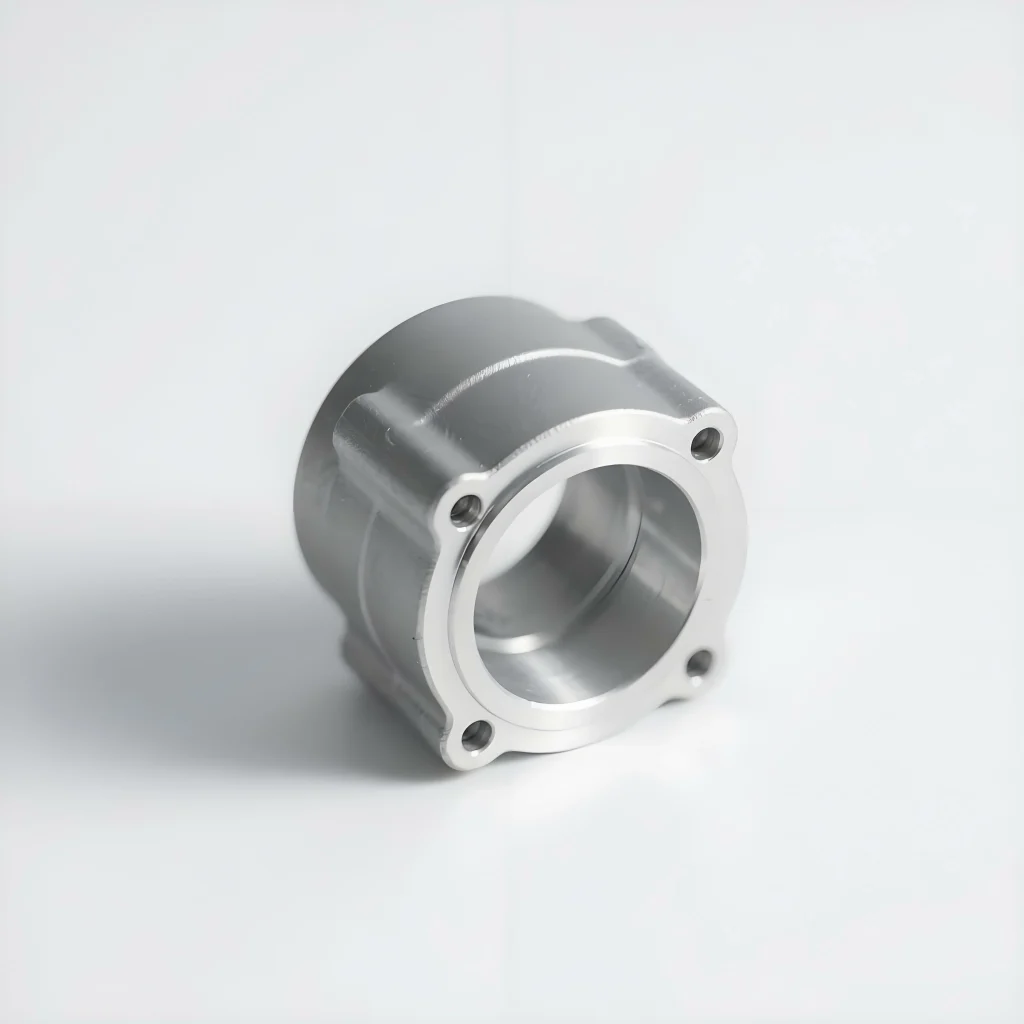

Many engineers and manufacturers pick zinc die casting because of its great zinc strength, accuracy, and affordability. At Welleshaft, we work with casting zinc and zinc alloy die casting daily, delivering reliable zinc die casting parts across various fields. This article explains how strong is zinc, dives into key properties of die cast zinc alloys, and shows why they’re popular from automotive to jewelry uses.

(1)Mechanical Strength: How Strong Is Zinc Die Cast?

People often ask, “is zinc alloy strong?” Well, die cast zinc is tough — some zinc alloys reach tensile strengths around 54,000 psi, especially when compared to aluminum. This makes die cast zinc alloy a solid choice for parts that take hits and stress, such as locks, brackets, or housings.

This strength shows up in areas like:

- Automotive, where Zink Edelmetall Verwendung in der Automobilindustrie helps parts last longer.

- Industrial machines needing corrosion resistance of zinc casting in heavy machinery.

- Electronics relying on zinc die casting parts for smartphone housingsand die cast zinc for LED lighting fixtures durability.

(2)Detailed Casting with Great Fluidity

One big plus of casting zinc is how easily it fills molds. Its smooth flow lets designers make thin walls and small features without extra cutting or shaping later. That saves time and money.

Jewelry makers like this too. They often ask “Wie stark ist Zinklegierung für Schmuck?” (How strong is zinc alloy for jewelry) and “how long does zinc alloy jewelry last,” since zinc alloys make strong, detailed, and long-lasting pieces.

2.Zinc Die Casting Saves Tool Life and Costs

(1)Lower Heat Means Tools Last Longer

Because die casting zinc melts at 700–800°F, it’s much cooler than aluminum’s 1,200°F. This means less damage to molds and longer tool life.

At Welleshaft, our tools often run over a million cycles — sometimes even three million — before needing replacement. This cuts downtime and helps keep the quality steady for parts like zinc casting parts for automotive fasteners and fittings and zinc alloy die cast parts for HVAC equipment.

(2)Smooth Finish and Rust Resistance

Zinc castings come out smooth, making them easy to paint or coat. Plus, metal zinc naturally fights rust. It forms a protective layer when exposed to air, which helps parts last longer outside.

This is why many trust zinc in cars and machines, relying on die cast zinc alloy corrosion resistance for cars and corrosion resistance of zinc casting in heavy machinery to reduce upkeep.

3.Zinc Is Good for Environment and Wallet

Zinc can be recycled over and over without losing strength. Also, since it melts at lower temps, it needs less energy to cast, which means lower costs and less pollution.

For companies watching their impact, zinc alloy die casting helps meet goals without giving up performance.

4.Common Zinc Alloys and Their Uses

| Alloy | Description | Typical Use Cases |

| ZAMAK 3 | Balanced strength and flow, most popular in North America | Everyday parts, automotive fasteners |

| ZAMAK 5 | Extra copper boosts strength and hardness | Parts that see more wear and tear |

| ZAMAK 7 | Better flow and finish for tricky shapes | Complex, detailed components |

| ZAMAK 2 | Hardest and strongest as-cast zinc alloy | Heavy-duty parts |

| ZA-8 | Handles higher temps well | HVAC parts and industrial tools |

| EZAC™ | Great creep resistance | Special auto and industrial pieces |

Picking the right zinc alloy die cast depends on what your part needs most.

5.Zinc Die Casting in Different Industries

(1)Automoción

- Zinc is widely used because of Zink Edelmetall Verwendung in der Automobilindustriefor making strong, rust-proof car parts.

- Zinc shows great die casting zinc strength for automotive engine partsand electrical housings.

- It’s also great for zinc casting parts for automotive fasteners and fittings, making cars more reliable.

(2)Jewelry

- People compare zinc alloy die cast vs brass for jewelry durability, and zinc often wins for strength and hypoallergenic traits.

- Many wonder “how long does zinc alloy jewelry last with regular use?” Zinc holds up well against wear.

- Die cast zinc alloy hypoallergenic jewelry benefitsattract many who need skin-friendly options.

- Top zinc casting jewelry manufacturers for custom designschoose zinc for its ease and detail.

(3)Electronics

- Strength of zinc alloy die cast for electronic enclosureshelps protect devices without adding much weight.

- Zinc is common in zinc casting in consumer electronics manufacturing, like phones and LED lights.

- People ask “is zinc alloy strong for handheld device casings?” Yes, it’s tough and keeps parts accurate.

(4)Industrial Machinery

- Zinc’s strength supports zinc die casting strength for industrial machinery components, even under rough conditions.

- It’s common in zinc alloy die cast parts for HVAC equipmentfor long-lasting performance.

- Zinc casting suppliers for manufacturing tools and partsrely on zinc to make sturdy, wear-resistant pieces.

- Die casting zinc for industrial fasteners and connectorshelps parts hold up under stress.

6.People Also Ask

(1)How strong is zinc die cast compared to aluminum?

A1: Zinc alloys usually have better impact resistance and hardness than aluminum, making them stronger for many uses.

(2)Which zinc alloys are best for die casting?

A2: The most common are ZAMAK 3 for general parts, ZAMAK 5 for more strength, and ZA-8 for hot environments.

(3)How long does zinc alloy jewelry last?

A3: Zinc jewelry can last years if cared for, thanks to corrosion resistance and durable alloy makeup.

(4)Is zinc alloy suitable for electronic device casings?

A4: Yes, it combines strength and precision, ideal for slim and sturdy device housings.

7.Final Thoughts

At Welleshaft, we know zinc die casting inside out. We help you pick the right casting zinc alloys and make sure your parts come out strong, sharp, and cost-effective. Whether you work in automotive, electronics, jewelry, or industrial fields, knowing how strong is zinc and choosing the right zinc alloy die cast can make a big difference in quality and price.