ACME Precision Threaded Rods for Industrial Applications

ACME Precision Threaded Rod: High-Precision Rods for Critical Applications

In precision industries, engineers rely on ACME precision threaded rods for accuracy, durability, and load control. Unlike standard fasteners, ACME rods—also called ACME screw rods—deliver smooth linear motion and reliable power transmission. They power lead screw systems, industrial actuators, lifting devices, and heavy automation equipment. Selecting the right rod-and-nut combination improves positioning accuracy, extends service life, and lowers maintenance costs. OEMs focus on thread precision, material consistency, and manufacturing stability when sourcing high-precision ACME rods for critical applications.

What Are ACME Precision Threaded Rods?

An ACME precision threaded rod uses a trapezoidal thread profile with a 29-degree included angle, making it ideal for efficiently transmitting axial loads and controlling linear motion. Unlike standard or partially threaded rods designed mainly for fastening, an ACME threaded rod runs the profile continuously along its length, which improves stability and wear resistance under heavy loads. As a result, it strikes a practical balance between strength, efficiency, and manufacturability—something square threads often struggle with. Commonly paired with ACME threaded nuts, flange nuts, or jam nuts, these rods form reliable lead screw assemblies for demanding systems. They’re widely available in inch sizes like 1 inch ACME threaded rod, 3/4 ACME threaded rod, and 1/2 ACME thread, while also being frequently compared with metric trapezoidal threaded rods in precision applications.

Key Features of ACME Precision Threaded Rods

High Load Capacity

One of the biggest advantages of ACME precision threaded rods is their ability to handle high axial loads safely and consistently. Thanks to the trapezoidal thread profile, contact between the rod and nut increases, so forces spread evenly across the thread flanks instead of concentrating at one point. As a result, wear is reduced and service life is extended. For example, a 3/4-5 ACME threaded rod can carry much higher working loads than a standard coarse thread of the same diameter. That’s why ACME threaded rods are widely used in lead screws, actuators, presses, lifting tables, positioning platforms, and heavy-duty screw jacks—applications where load stability and long-term reliability truly matter.

Durability and Strength

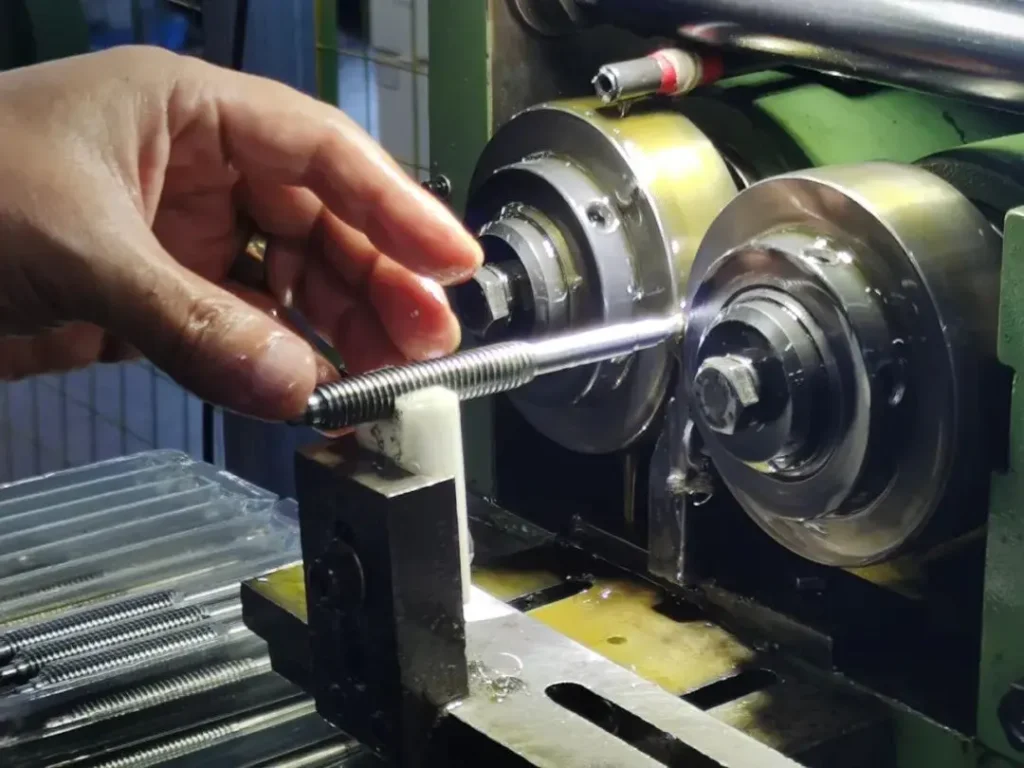

ACME precision threaded rods are built for tough, real-world industrial use, and material choice plays a big role in that performance. They’re commonly produced from carbon steel, alloy steel, stainless steel ACME threaded rods, or brass threaded rods for corrosion-sensitive or non-sparking environments. When manufacturers use rolled threads instead of cut threads, the result is better grain flow, higher fatigue resistance, and a noticeably longer service life. As a result, ACME threaded rods outperform standard metal threaded rods in continuous-duty applications, especially where vibration, shock loads, and repeated linear motion are part of daily operation.

Smooth Operation

The trapezoidal design of ACME threaded rods ensures smooth and efficient linear motion, reducing friction and wear between the rod and nut. This not only lowers maintenance needs but also delivers quieter operation and consistent positioning over time. That’s why ACME screw rods are widely preferred in automation systems, machine tools, and precision handling equipment, often outperforming square threaded bars and even ball screws in high-load, moderate-speed applications where reliability and smooth motion are critical.

Do You Know The Main Differences Between ACME Thread and Standard Thread

Thread Profile

Standard threads typically have a sharp V-shaped profile designed mainly for fastening, but ACME threads feature a trapezoidal profile with flat crests and roots, which spreads loads more evenly and reduces stress concentration. This design not only improves load-bearing capacity and lowers friction but also makes ACME threaded rods far more reliable for high-load, motion-based applications, outperforming conventional threaded bars in industrial equipment, actuators, and precision systems.

Thread Angle

The thread angle is a key factor that sets ACME threads apart from standard threads. With an included angle of 29°, compared to the 60° of standard V-threads, ACME threaded rods reduce radial forces, improve power transmission efficiency, and minimize wear over time. This makes them ideal for high-load, motion-critical applications where reliability and longevity matter.

| Thread Type | Included Angle | Typical Use |

| ACME thread | 29° | Power transmission, actuators, lead screws |

| Standard V-thread | 60° | Fastening, general assembly |

By optimizing the angle, ACME thread rods deliver smoother operation, longer lifespan, and superior performance in industrial and automation systems.

Load Distribution

ACME threaded rods and nuts distribute axial loads evenly, reducing stress and preventing premature wear. Standard rods often fail to do this, especially under reversing or dynamic forces. This even load handling makes ACME rods ideal for lead screws, actuators, and heavy-duty industrial systems where reliability matters.

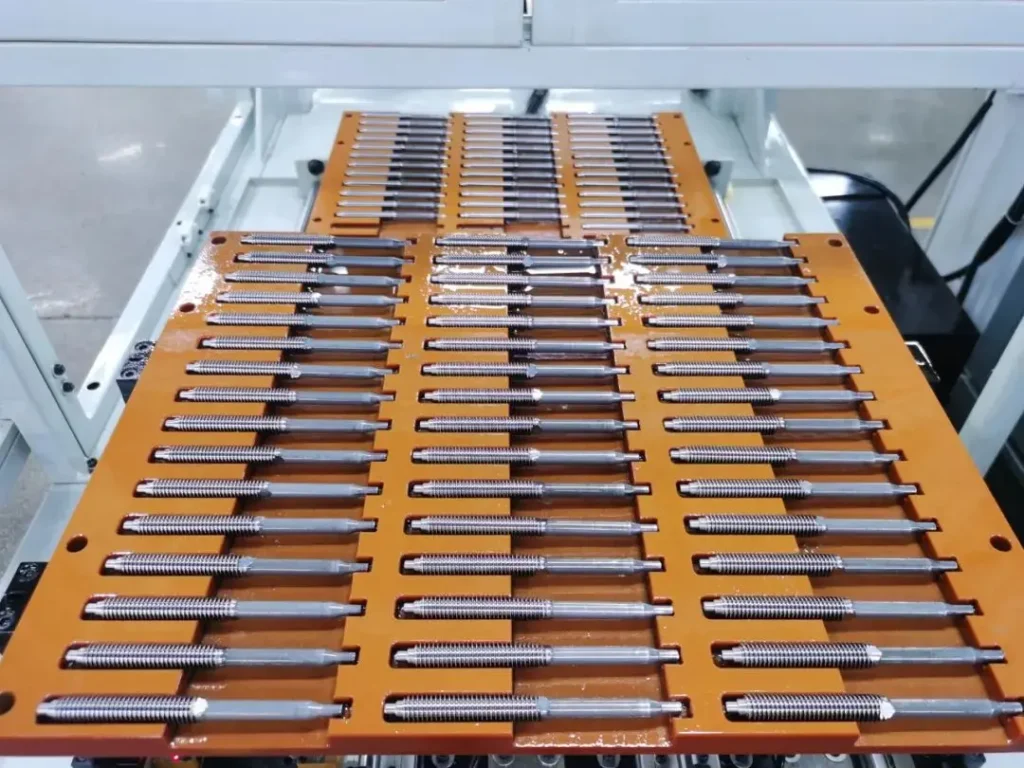

ACME Thread Sizes and Types

ACME threaded rods are available in various sizes and types to fit any project. Choose 3/4″-8 rods for versatile industrial use, stainless steel rods for corrosion resistance, or brass rods for non-sparking applications. Buyers often check threaded rod size charts and ACME thread specs to ensure optimal performance and durability

ACME Thread Chart

Choosing the right ACME threaded rod starts with a reliable ACME thread chart or threaded rod diameter chart. These charts list key specs like thread pitch, diameter, and length, helping engineers prevent mismatched parts and early failure. Popular sizes and applications include:

| Nominal Size | Threads Per Inch (TPI) | Common Applications |

| 1/2 ACME | 10 TPI | Light actuators |

| 3/4-5 ACME | 5 TPI | Lead screws |

| 1 inch ACME | 5 TPI | Heavy lifting systems |

Using these charts ensures precise selection, boosts performance, and extends rod lifespan.

ACME Thread Calculator

An ACME thread calculator helps you quickly determine thread pitch, lead, load capacity, and efficiency. Engineers use it to design custom rods, oversized components, or replace lead screw assemblies, ensuring compatibility with ACME nuts and predictable performance. By considering material properties and load requirements, they optimize designs, prevent costly errors, and extend product lifespan.

Applications of ACME Precision Threaded Rods

Lead Screws

ACME lead screws and rods convert rotational motion into precise linear movement, making them essential for machine tools, positioning tables, and automation systems. Their high precision and durability ensure reliable performance under demanding conditions. Engineers select the right ACME rods for lead screws to optimize accuracy, reduce maintenance, and extend system lifespan.

Actuators

In linear actuators, ACME threaded rods and ACME screw nuts deliver precise, controlled motion with high load capacity, ensuring smooth and reliable operation. Widely used in material handling systems, assembly lines, and adjustable platforms, these components combine precision and durability to optimize performance. By selecting the right ACME rods for actuators, engineers can improve efficiency, reduce wear, and extend the system’s lifespan.

Industrial Equipment

From packaging machinery to heavy presses and lifting devices, a wide range of industrial equipment relies on ACME threaded rods for precise, dependable motion control. Their combination of strength, durability, and accuracy ensures smooth operation in automation systems, machine tools, and other performance-critical applications. By choosing the right ACME threaded components, engineers can enhance efficiency, reduce downtime, and extend equipment lifespan.

Why Choose Welleshaft for ACME Precision Threaded Rods?

Choosing the right ACME threaded rod supplier is crucial for industrial projects, and Welleshaft delivers unmatched reliability. With strict quality control across material selection, thread rolling, machining, and inspection, every ACME precision threaded rod meets exacting dimensional and performance standards. Beyond standard sizes, Welleshaft offers custom ACME threaded rods, lead screws, and nut assemblies, ensuring tailored solutions. As a trusted global supplier, Welleshaft guarantees consistent quality, stable lead times, and worldwide delivery for projects requiring dependable high-precision ACME rods.

ACME Precision Threaded Rod FAQ’S

What Are ACME Threads and How Are They Different?

ACME threads have a wider profile and 29° angle, unlike standard screw threads. They make ACME threaded rods and nuts smooth, strong, and ideal for lead screws, precision threaded products, and heavy-duty machinery. Knowing ACME thread dimensions helps you pick the right dependable ACME threaded products.

How Do I Choose the Right ACME Threaded Rod?

Pick your ACME threaded rod based on size, pitch, and material. Options range from 1 inch ACME threaded rods to 3/4 ACME threaded rod and nuts, plus custom ACME threaded rods if you need special dimensions or materials. Using a trusted ACME threaded rod manufacturer ensures precision and reliability.

Why Use ACME Thread Rods and Nuts?

ACME rods and nuts give smooth motion, handle heavy loads, and reduce backlash. They’re perfect for lead screws, industrial threaded rods, and precision machinery. Variants like coarse threaded rods or square threaded rods meet different project needs while keeping performance consistent.

This blog was provided by the Welleshaft Engineering Team, led by Mr. Xu, who has over 20 years of experience in ACME precision threaded rods and industrial automation solutions.