1.What to Know About Zinc Alloys for Casting | Welleshaft

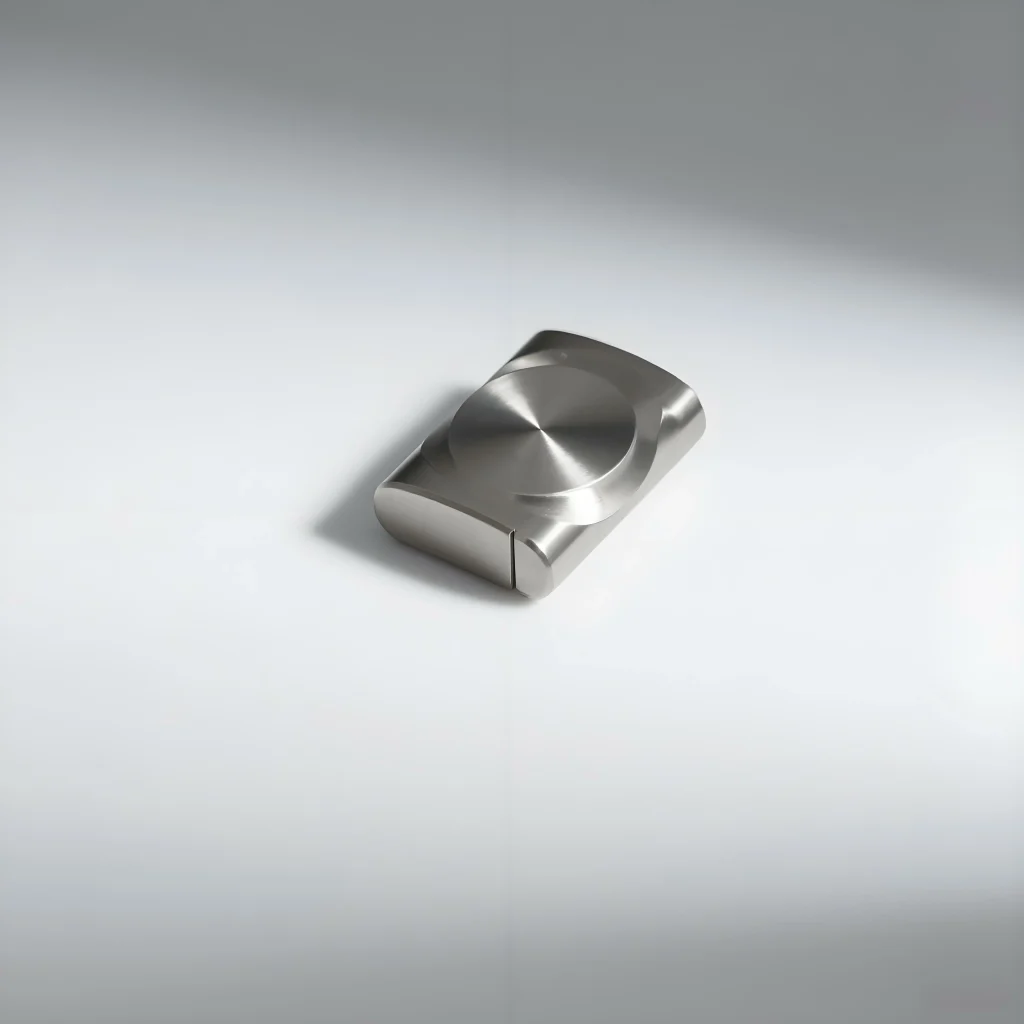

Zinc alloys stay a reliable pick when it comes to precision casting. Thanks to their low melting temp, resistance to rust, and shaping flexibility, zinc alloy casting holds its ground in today’s factories. What is zinc alloy material? At Welleshaft, we build custom cast zinc parts for machinery, electronics, car parts, and even medical tools.

This guide walks you through alloys with zinc, how casting zinc works, common types like ZAMAK, and why zn alloys make sense in real-world production.

2.Properties of Zinc Alloys

(1)What Is Zinc Alloy Material?

Mostly made of zinc with some aluminum, magnesium, and copper mixed in, zinc alloys bring the right combo of strength and stretch. These industrial zinc alloys with copper and magnesium handle tough jobs—like zinc alloy materials for medical device casings o casting zinc for precision medical parts.

(2)Zinc Alloy Melting Point

Zinc’s low melting temp makes it ideal for quick casting. Most zinc alloy melting point numbers sit between 370°C and 420°C (698°F to 788°F). ZAMAK melting point values inch higher with extra metals in the mix.

①Zinc Alloy Melting Points

| Alloy Type | Melting °C | Melting °F |

| Zamak 2 | 380 | 716 |

| Zamak 3 | 387 | 729 |

| Zamak 5 | 385 | 725 |

| ZA-8 | 395 | 743 |

Engineers often check the zamak melting point chart for engineers before choosing high-strength alloys with zinc for tooling or working on zamak alloys in medical manufacturing.

3.Common Types of Zinc Alloys

(1)ZAMAK Family: Zinc, Aluminum, Magnesium, Copper

①Zamak 3

Used across the U.S., Zamak 3 offers top-notch flow in casting and stays dimensionally stable. It’s behind a lot of zinc alloy for costume jewelry making, whats zinc alloy in fashion accessories, locks, and zinc alloy casting for phone and tablet bodies.

②Zamak 5

A bit stronger with about 1% copper, Zamak 5 is common in Europe. It’s perfect for casting zinc for automotive housing components and comparing zinc alloy vs aluminum for casting parts.

③Zamak 2

This one’s older than Zamak 3 but stronger than both Zamak 3 and 5. It’s used when you need hard-wearing results in casting zamak fixtures or commercial-grade zinc alloys for fabrication.

④ZA-8

A zinc-aluminum blend with around 8% aluminum, ZA-8 brings the heat—literally. It’s great for casting zinc for EMI shielding in devices, zinc alloy vs aluminum for electronics casing, and situations like melting point of zn alloys for sterilization environments.

4.Zinc Alloy Casting Process

(1)How to Cast Zinc Alloy for Industrial Use

We mostly use die casting to shape zinc allow. The molten zink alloy shoots into a steel mold under pressure and takes the shape with tight precision. This is how we get sharp, clean forms in big production runs.

(2)Why Die Casting Works

- Quick cycles

- Spot-on repeatability

- Handles tricky shapes

- Mold reuse keeps costs down

(3)Where Zinc Alloy Casting Shows Up

- Auto: Engine shells, mounts, trim. See zn alloys melting points for automotive design.

- Médico: Tools, casings. Think what is zinc alloy in surgical tools.

- Electronics: Casings and zinc alloys for electronic housing components.

- Everyday goods: Door locks, knobs, best casting zinc alloys for jewelry design.

5.Advantages of Zinc Alloys for Casting

- Melts Low: Needs less heat, good for zinc alloy melting point in Fahrenheitwork

- Rust-Resistant: Use it outside or in hospitals

- Strong & Tough: Zamak 2 and ZA-8 shine here

- Great for Detail: Works well in molds and zinc allow color and polish options for accessories

- Saves Money: Smart for volume runs, especially with commercial-grade zinc alloys for fabrication

Whether you’re weighing zinc alloy vs aluminum for casting parts or exploring safe zinc alloys for skin-contact items, it helps to first ask: what is zinc alloy material? At Welleshaft, we guide you toward the right choice for your application.

6.People Also Ask

(1)What is zinc alloy used for in manufacturing?

Zinc alloys help make lasting parts in cars, medical tools, gadgets, and home items. Some examples? Custom cast zinc parts for machinery y zinc alloy materials for medical device casings.

(2)How does zinc alloy differ from aluminum in casting?

Zinc alloys melt easier and fill molds better. Aluminum wins when weight matters. You’ll see this debate in zinc alloy vs aluminum for electronics casing.

(3)Are zinc alloys skin-safe?

Yep. Safe zinc alloys for skin-contact items like jewelry and belts are built to avoid allergic reactions.

(4)Are zinc alloys good for electronics?

Sure are. Zinc alloys for electronic housing components add strength and stop EMI, a win when casting zinc for EMI shielding in devices.

7.Conclusión

Still wondering, what’s zinc alloy? This guide covers everything from zamak melting point to how to cast zinc alloy for industrial use. At Welleshaft, we handle jobs where zinc alloy casting makes the most sense.

Looking to compare zinc alloy vs aluminum for electronics casing? Or figure out the melting point of zn alloys for sterilization environments? You’re in the right place.

We’ve worked with zinc alloy materials for medical device casings, zinc allow color and polish options for accessories, and even casting zinc for EMI shielding in devices. Reach out to Welleshaft and find out how alloys with zinc can work for your next part run.