What is a Skived Fin Heat Sink?

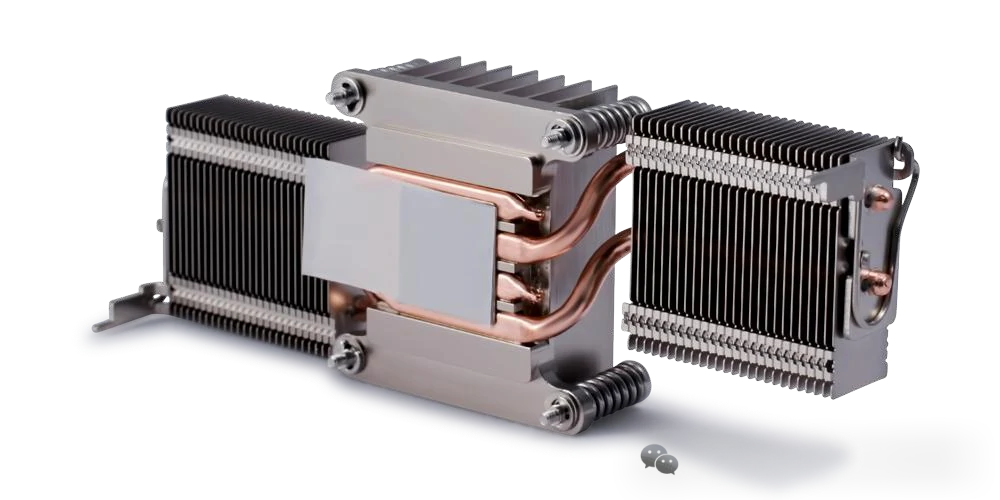

High-Performance Skived Fin Heat Sinks are high-performance thermal solutions designed to maximize heat dissipation in compact electronics. Unlike standard heat sinks, High-Performance Skived Fin Heat Sinks feature precision-cut fins from a single metal block, providing superior thermal conductivity and structural integrity.Engineers often ask, “What is a Skived Fin Heat Sink?” Welleshaft offers High-Performance Skived Fin Heat Sink Supplier services for LEDs, GPUs, and automotive modules, ensuring consistent thermal performance and system reliability.

Principle and Skiving Process Workflow

En Skiving Process slices fins from solid aluminum or copper blocks using CNC-controlled skiving machines. Fins are simultaneously formed and bent to the required angle, maintaining uniform thickness (0.1–0.3 mm) and high-density arrangement. Welleshaft’s workflow includes:

- Material Preparation– selecting aluminum or copper based on conductivity requirements.

- Precision Skiving– slicing fins with high-speed cutting tools.

- Module Assembly– integrating skived fins with heat pipes or baseplates.

- Thermal Simulation & Verification– CFD analysis and performance testing.

This ensures High-Efficiency Skived Heat Sink designs for LEDs, GPUs, and server racks.

Material Selection: Aluminum vs Copper Skived Fin Heat Sinks

Material choice affects thermal efficiency, weight, and cost. Copper Skived Fin Heat Sinks deliver the highest thermal conductivity, ideal for GPUs and high-power LEDs. Aluminum Skived Fin Heat Sinks are lightweight, suitable for automotive and telecom modules. Welleshaft provides guidance as a Skived Fin Heat Sink Supplier, helping clients choose the optimal material. Customers can request a High-Performance Skived Fin Heat Sink price quote for evaluation.

Precision Skived Heat Sink Applications

Precision Skived Heat Sink technology is widely used in:

- GPU cooling

- LED lighting boards

- Industrial power modules

Benefits include reduced junction temperature, longer component lifespan, and efficient airflow management. Engineers often ask, “Why use a Precision Skived Heat Sink for CPU cooling?” Welleshaft supports custom Skived Fin Heat Sink orders for OEM and industrial applications.

Advanced Skiving Process Explained

Nuestra Advanced Skived Fin Heat Sink manufacturing uses CNC precision skiving technology. Compared to extruded or bonded heat sinks, it enables:

- High-density fin arrangements

- Uniform thickness and flatness

- Lightweight and high-performance modules

Welleshaft combines skiving, CNC machining, thermal simulation, and QA inspection to deliver repeatable results for high-power electronics, automotive, and LED applications.

Skived Thermal Modules for Automotive & Telecom Applications

Skived Thermal Modules integrate high-efficiency skived fins with custom heat pipes to maintain stable operating temperatures. They are essential for EV battery cooling, telecom systems, and automotive electronics. Engineers ask, “What is a Skived Thermal Module used for?” Welleshaft offers OEM, bulk orders, and fast shipping from USA suppliers, ensuring reliability in high-demand applications.

Comparison: Skived vs Standard Heat Sinks

Understanding the difference between Advanced Skived Fin Heat Sink and standard heat sinks is crucial. Skived fins provide:

- Higher thermal performance

- Better airflow management

- Lightweight design

- Tighter fin spacing

Welleshaft Services and Technical Capabilities

Welleshaft offers end-to-end services, including:

- Custom Skived Fin Heat Sink Manufacturing

- High-Performance Skived Fin Heat Sink Supplier Solutions

- Skived Fin Heat Sink Quality Inspection & Pre-Shipment Verification

Our capabilities: ISO-certified CNC machines, thermal testing labs, and expert engineers. Clients benefit from design consultation, OEM support, and Skived Fin Heat Sink QA services.

Customer Case Studies

- LED Manufacturer:Reduced junction temperature by 25% using High-Performance Skived Fin Heat Sinks.

- GPU OEM:Achieved consistent high-density fins via Precision Skived Heat Sink Supplier

- EV Battery Cooling:Custom Skived Thermal Modules maintained safe temperatures across high-load cycles.

Skived Fin Heat Sink Selection & Inspection

(1)Which Skived Fin Heat Sink is best for server racks?

High-density aluminum or copper skived fin heat sinks are ideal. See High-Performance Skived Fin Heat Sink Cluster page.

(2)How to select the right Skived Fin Heat Sink for high-power electronics?

Consider fin density, material, thermal resistance, and airflow. Welleshaft provides Skived Fin Heat Sink inspection services.

(3) Where can I find custom Skived Fin Heat Sinks for industrial electronics?

Welleshaft offers OEM and custom solutions with pre-shipment inspection and technical support.

Written by Welleshaft’s senior thermal engineer with 7 years of experience in advanced heat sink solutions for industrial electronics, automotive, and LED lighting applications. Expertise includes Skived Fin Heat Sink, High-Performance Skived Fin Heat Sink, and Precision Skived Heat Sink solutions.