1.Regional Aluminum Heat Sink Inspection Services: Ensuring Quality and Reliability

Aluminum heat sinks are vital in modern electronics, industrial machinery, and thermal management applications. Selecting the right aluminum heat sink inspection service is critical for ensuring device longevity, performance, and compliance with industry standards. Companies increasingly demand heat sink quality inspection y aluminum heat sink testing service solutions from providers who can deliver reliable results with fast turnaround. Understanding local inspection capabilities, service standards, and quality assurance processes is essential for operational efficiency and selecting reliable Regional Aluminum Heat Sink Inspection Services.

Whether you are searching for aluminum heat sink inspection service near me or evaluating regional aluminum heatsink inspection providers, this guide will provide a detailed walkthrough of what to consider when choosing a professional inspection partner.

2.Why Regional Aluminum Heat Sink Inspection Matters

(1)The Need for Reliable Local Inspection Services

Global electronics manufacturers face challenges with supply chain delays, inconsistent QC reports, and high transportation costs when sending heat sinks for testing to distant facilities. Engaging a local heat sink QC service for manufacturers reduces lead times and allows immediate corrective action for defects detected in heat sink evaluation service o heatsink defect inspection.

Key advantages of working with regional providers include:

1.Faster turnaround for urgent inspection requests.

2.Direct oversight by quality engineers familiar with local industry regulations.

3.Reduced shipping costs and handling risks.

By leveraging nearby professional heat sink testing service, companies can maintain production schedules without compromising quality.

3.Core Components of Aluminum Heat Sink Testing

(1)Heat Sink Performance Testing

Aluminum thermal management inspection focuses on verifying thermal conductivity, airflow optimization, and material properties. Heat sink performance testing ensures that the component will dissipate heat efficiently under operational conditions.

Steps involved in performance testing typically include:

1.Thermal resistance measurement.

2.Temperature mapping under simulated load conditions.

3.Mechanical stress evaluation for mounting points.

4.Comparison with OEM or design specifications.

(2)Heatsink Quality Control Service

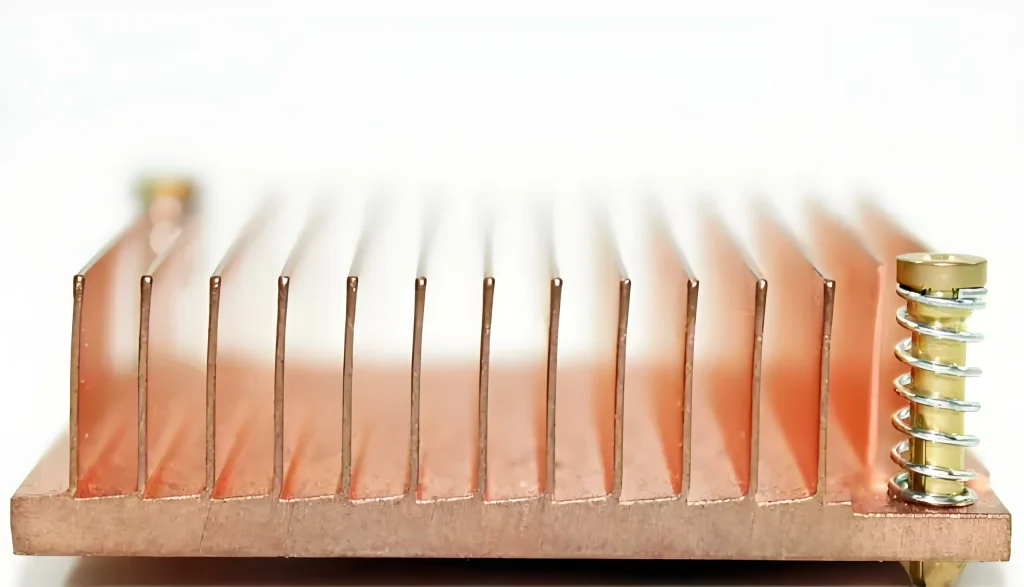

A thorough heatsink quality control service evaluates the manufacturing quality, including surface finish, fin integrity, and dimensional tolerances. Inspectors use:

1.Optical inspection systems.

2.Laser scanning for geometric accuracy.

3.Profilometry for surface roughness.

Companies seeking thermal component inspection service rely on these methods to reduce the risk of premature device failure.

4.Types of Aluminum Heat Sink Inspection Services

(1)Visual and Dimensional Inspection

Aluminum heatsink inspection begins with a visual assessment to identify obvious defects, followed by precise dimensional verification using calipers, CMMs, or 3D scanners. This is crucial for components that must fit precisely in assemblies.

(2)Thermal and Electrical Testing

Advanced heat sink testing and inspection ensures that thermal performance meets design criteria. Some services include infrared thermal imaging, heat flux analysis, and cold/hot junction tests. Thermal heat sink inspection is essential for high-power electronics or densely packed assemblies.

(3)Defect Analysis

Heatsink defect inspection identifies common issues such as:

1.Warped fins.

2.Oxidation or surface contamination.

3.Poor bonding in composite or hybrid materials.

A reliable heat sink inspection and QC service for electronics locally will document all defects and provide actionable recommendations.

5.How to Choose a Local Heat Sink QC Service

(1)Location and Responsiveness

Selecting regional aluminum heatsink inspection providers ensures quick access to testing facilities. Consider whether the provider can schedule heat sink inspection service near my facility and handle high-volume requests efficiently.

(2)Certifications and Standards

Check if the service adheres to recognized heat sink manufacturing inspection standards, such as:

1.ISO 9001 for quality management.

2.MIL-STD thermal testing protocols.

3.RoHS and REACH compliance for materials.

(3)Equipment and Capabilities

Look for advanced testing equipment capable of:

1.Measuring thermal resistance and conductivity.

2.Conducting aluminum heatsink inspection with ±2 μm tolerance for critical components.

3.Automated reporting and data traceability.

6.Common Questions About Regional Aluminum Heat Sink Inspection

1.Where can I find aluminum heat sink inspection services near me?

Search for providers specializing in local industrial heat sink inspection solutions and check reviews or references from nearby manufacturers.

2.How fast can local heat sink inspection be scheduled?

Reliable regional providers can typically accommodate urgent inspections within 24–72 hours.

3.Which regional heat sink testing services are reliable?

Evaluate experience, equipment, certifications, and case studies demonstrating successful aluminum heat sink testing service delivery.

4.Can nearby QC services handle high-volume heat sink inspections?

Reputable providers maintain multiple inspection lines and trained staff for batch testing, ensuring consistent heatsink quality control service.

5.How much does local aluminum heat sink inspection cost?

Costs vary depending on volume, complexity, and testing methods. Many providers offer a cost of regional aluminum heat sink inspection service quote per unit or batch.

6.Are there certified heat sink inspection services in my area?

Look for ISO, MIL-STD, or industry-specific accreditations. This ensures compliance with aluminum heatsink QC service standards.

7.How to verify quality of regional heat sink inspection providers?

Request sample reports, audit trails, and references. Confirm adherence to heat sink inspection and QC service for electronics locally.

7.Benefits of Engaging Regional Aluminum Heat Sink Inspection Services

1.Reduced Turnaround Time: Immediate inspection reduces assembly delays and production bottlenecks.

2.Local Support: On-site or nearby engineers can address issues in real time.

3.Enhanced Compliance: Ensures adherence to industry standards for aluminum heat sink quality inspection.

4.Cost Efficiency: Minimized shipping and logistics expenses.

5.Scalable Solutions: From single prototype inspections to high-volume batch testing.

8.Best Practices for Regional Heat Sink Inspection

1.Define Critical Parameters Early: Ensure your provider knows the thermal and mechanical tolerances required.

2.Integrate Inspection in Manufacturing: Schedule aluminum heat sink inspection service near me at multiple points to catch defects early.

3.Document Findings: Use automated reporting to track heat sink performance testing results and heatsink defect inspection.

4.Continuous Improvement: Feed inspection data back to design and production teams for enhanced reliability.

This article is produced by the Welleshaft Technical Content Team, composed of certified engineers and QC specialists with over a decade of experience in thermal management and electronics manufacturing. Welleshaft provides aluminum heat sink inspection service near me, heat sink evaluation service, and thermal component inspection service for global clients, ensuring compliance, performance, and operational efficiency.