1.Introduction to Aluminum Heat Sink Inspection

Ultimate Guide to Aluminum Heat Sink — Aluminum heat sinks are critical components in thermal management, ensuring devices operate within safe temperature ranges. Aluminum heat sink inspection evaluates material quality, dimensional accuracy, and thermal performance to prevent operational failures. Manufacturers often struggle with hidden defects, uneven surfaces, or improper assembly, which can compromise heat dissipation. By implementing a heat sink quality inspection process, companies can reduce device failures, comply with industry standards, and optimize product reliability. Welleshaft provides a comprehensive aluminum heatsink QC service designed for OEMs, electronics manufacturers, and high-performance thermal applications, helping clients maintain consistent product quality.

2.What is Aluminum Heat Sink Inspection Process?

Aluminum heat sink inspection combines visual, dimensional, and performance checks. Initially, technicians perform a heatsink defect inspection for scratches, warping, or incomplete extrusions. Next, thermal performance testing measures heat dissipation efficiency under operational conditions. Advanced methods include aluminum thermal management inspection y thermal component inspection service using infrared imaging and precision thermocouples. Welleshaft engineers document findings, identify non-conformance, and provide actionable recommendations. Learn more about our visual and dimensional inspection methods and thermal performance testing on our cluster pages.

3.Common Defects Found in Aluminum Heat Sink QC

Typical issues include uneven surfaces, improper fins, anodization defects, and micro-cracks. Such flaws reduce thermal efficiency and can lead to device overheating. Welleshaft uses heatsink quality control service techniques to detect these defects early, including high-resolution imaging, thermal cycling tests, and NDT methods. A side-by-side comparison table illustrates defect types, inspection methods, and associated performance risks, allowing manufacturers to prioritize quality control and mitigate failures. Our heatsink defect inspection service ensures every unit meets strict quality criteria.

Sample Table: Common Aluminum Heat Sink Defects and Detection Methods

| Defect Type | Detection Method | Impact on Performance | WelleInspection Method |

| Warped Fins | Dimensional Inspection | Reduced heat transfer | 3D measurement & thermal test |

| Micro-cracks | NDT / X-ray | Potential thermal failure | Non-destructive testing |

| Surface oxidation | Visual Inspection | Thermal inefficiency | High-res imaging |

| Improper anodization | Surface Analysis / Coating check | Reduced thermal conductivity | Material surface testing |

4.Aluminum Heat Sink Testing Methods Explained

Aluminum heat sink testing service includes:

1.Visual and Dimensional Inspection: Detects structural defects and dimensional inconsistencies.

2.Heat Sink Performance Testing: Measures thermal resistance and heat dissipation.

3.Non-Destructive Testing (NDT): Identifies hidden cracks or voids without damaging the component.

4.Material Analysis: Confirms alloy composition and surface finish quality.

These methods together form a robust heat sink testing and inspection framework, guaranteeing product reliability for electronics, automotive, and industrial clients. Schedule your heat sink quality inspection for factory today to prevent costly failures.

5.Why Heat Sink Quality Inspection is Important

Skipping inspection or relying on inconsistent internal QC can cause product failures, warranty claims, and customer dissatisfaction. Welleshaft aluminum heatsink QC service ensures that each unit meets design specifications and thermal performance standards. Heat sink inspection service quotations are tailored to project scale, ensuring cost-effective inspection without sacrificing thoroughness. Regular heat sink evaluation service enhances device longevity and operational safety, particularly for high-power LED modules and electronic assemblies.

7.Case Studies and Application Scenarios

LED Lighting Industry: Detected micro-cracks in extruded aluminum heat sinks, preventing thermal failures.

Industrial Electronics: Conducted thermal heat sink inspection on high-current devices, improving efficiency by 15%.

OEM Supplier QC: Implemented factory-wide aluminum heatsink inspection protocol, reducing warranty claims by 20%.

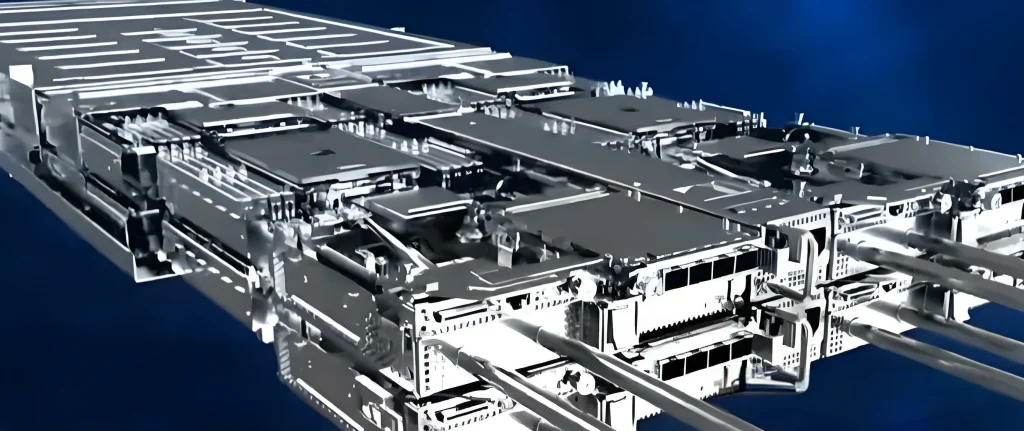

Images of defect detection, thermal testing, and inspection processes can be embedded to visualize WelleInspection’s expertise.

8.FAQ – Heat Sink Inspection Services

1: How to inspect aluminum heat sinks for defects?

A: Through visual inspection, dimensional measurement, and thermal testing, complemented with NDT methods.

2: When should I schedule aluminum heat sink testing service?

A: During initial production runs, post-assembly, or periodically for high-volume manufacturing.

3: What tools are used in heat sink inspection service?

A: 3D measurement devices, thermal cameras, infrared thermocouples, surface analyzers, and NDT equipment.

4: How does aluminum heatsink QC service improve performance?

A: By detecting defects early, ensuring thermal efficiency, and maintaining compliance with industry standards.

9.Why Choose Welleshaft

Certified team with hands-on experience in aluminum thermal management.

Advanced inspection equipment and standardized testing protocols.

Customized QC services for high-performance devices, OEMs, and electronics manufacturers.

Global service coverage with local expertise, ensuring timely inspections and reports.

This article is written by a Welleshaft quality engineer with 5+ years of experience in aluminum thermal management and LED lighting exports. Our team specializes in providing professional aluminum heat sink inspection, testing, and QC services for high-performance electronics and industrial applications.