High-Performance Skived Heatsink Manufacturing and Precision Fin Machining | Welleshaft

What is Skived Fin Machining and High-Performance Skived Heatsink Manufacturing?

Skived Heatsink Manufacturing and Precision Fin Machining are critical for efficient thermal management in electronics, automotive, LED, and telecom applications. Welleshaft specializes in precision skived fin fabrication, copper and aluminum skived fin heat sinks, and high-density skived fins to maximize thermal conductivity. Our end-to-end Skived Heatsink Manufacturing and Precision Fin Machining production ensures reduced thermal resistance, consistent quality, and compliance with ISO/ASTM/GB standards. Learn more about our precision skived fin machining solutions.

The Skiving Process in Precision Skived Fin Heat Sink Fabrication

Overview of Skived Fin Technology for High-Performance Heatsinks

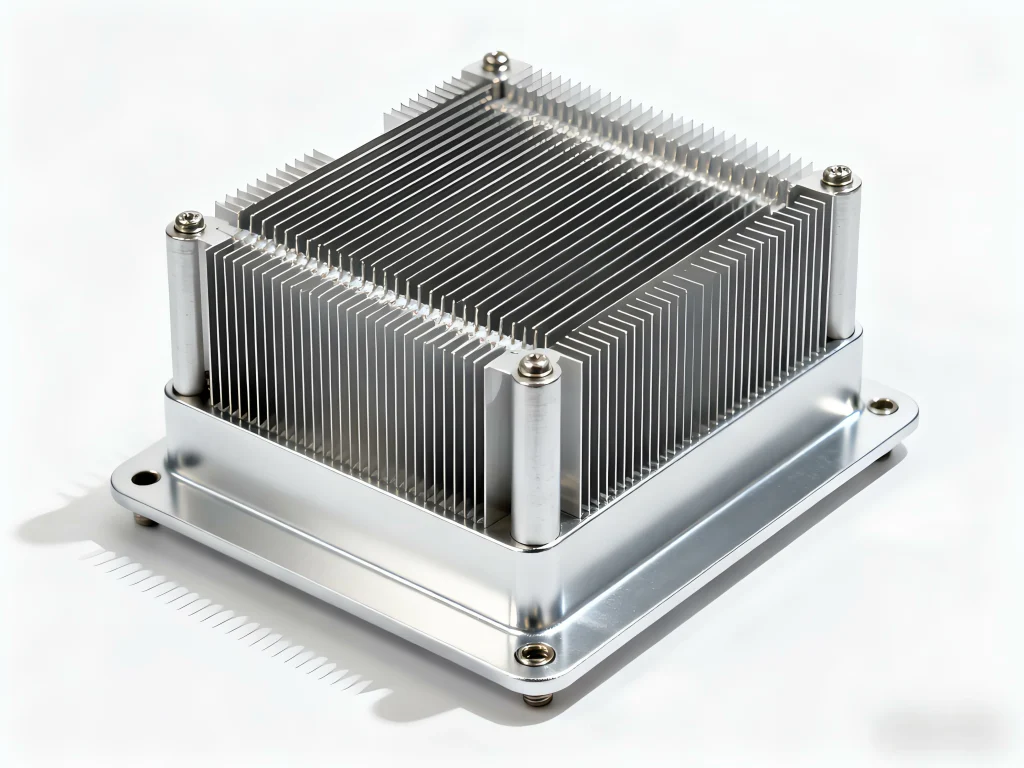

The skiving process involves cutting thin metal fins directly from a solid copper or aluminum base, producing high-density skived fins with superior thermal conductivity. Compared to stamped or extrusion methods, skived fin technology improves heat transfer efficiency while maintaining tight dimensional tolerances. Welleshaft’s skived heatsink fabrication ensures reliable performance for high-power LED, telecom, and automotive devices.

Step-by-Step Skived Fin Machining for Aluminum and Copper Heatsinks

Our precision skived fin machining process begins with high-grade copper or aluminum blanks, followed by advanced skiving using CNC-controlled machines. Fins are cut to exact thickness, height, and spacing, then assembled into high-performance skived heatsinks. This method optimizes thermal conductivity skived heat sink performance for industrial and OEM applications.

Advantages of Skived Heatsink Manufacturing and Precision Fin Machining

High-Density Skived Fins for Superior Thermal Management

High-density skived fins allow more surface area in a compact space, enhancing heat dissipation. Welleshaft’s skived fin fabrication and skived heatsink production reduce thermal resistance, improving device longevity and reliability. Ideal for data centers, power electronics, and high-power LEDs, these solutions are widely adopted in global OEM projects.

Benefits of Copper and Aluminum Skived Fin Heat Sinks

Copper skived fin heat sinks provide higher thermal conductivity for demanding applications, while aluminum skived heatsink manufacturing offers lighter weight and cost efficiency. Welleshaft provides custom skived fin production and precision skived fin machining for both metals, ensuring optimal thermal management tailored to client needs.

Skived Fin Machining vs Extrusion: A Technical Comparison

Precision skiving heat sink fabrication differs from extrusion in thermal efficiency, fin density, and dimensional accuracy. Skived fin machining enables higher fin density with tighter tolerances, while extrusion may limit fin height and thermal performance. Welleshaft’s high-performance skived heatsink fabrication leverages advanced skived fin technology to achieve superior results for automotive, telecom, and industrial electronics.

Welleshaft Services and Capabilities in Skived Heatsink Production

Custom Skived Fin Production and Assembly Solutions

We provide end-to-end skived heatsink assembly, skived fin cutting services, and custom skived fin production for industrial and OEM applications. Our thermal management skived fin solutions ensure high-performance cooling for LEDs, automotive electronics, and telecom devices.

Technical Expertise, Certifications, and Advanced Equipment

Welleshaft operates ISO/ASTM/GB-compliant skived heatsink manufacturing lines with CNC-controlled skiving machines. Our team’s expertise in precision skived fin machining and high-density skived fins ensures reliable quality, repeatability, and performance for global clients.

Applications of High-Performance Skived Heatsinks

High-performance skived heatsink fabrication is essential in automotive cooling systems, telecom base stations, LED lighting, and power electronics. Welleshaft’s copper and aluminum skived fin heat sinks optimize thermal conductivity, reduce heat stress, and extend device life across multiple industries worldwide.

Client Case Studies in Precision Skived Fin Machining

| Parameter | Before Welleshaft | After Welleshaft | Improvement % |

| Fin Density (fins/cm) | 5–6 | 8–10 | 60% |

| Thermal Resistance (°C/W) | 0.45 | 0.28 | 38% |

| Delivery Time | 6 weeks | 3 weeks | 50% |

Welleshaft implemented high-density skived fin heatsink production for a global LED OEM, resulting in reduced thermal resistance, faster delivery, and improved system reliability.

FAQ: Skived Heatsink Manufacturing and Fin Machining

(1)What is skived fin machining for heatsinks?

Skived fin machining cuts fins directly from a metal base, providing high-density, high-thermal-conductivity heat sinks.

(2)How does skived heatsink manufacturing improve thermal performance?

By increasing surface area and fin density, thermal conductivity skived heat sinks efficiently dissipate heat from high-power devices.

(3)Why choose precision skived fin technology over extrusion or stamping?

It provides superior dimensional accuracy, higher fin density, and better thermal performance, ideal for LEDs, automotive, and telecom applications.

En Welleshaft engineering team specializes in high-performance skived heatsink manufacturing, precision skived fin machining, and thermal management solutions for industrial, automotive, and LED applications. With over 10 years of experience and ISO/ASTM/GB certifications, we help clients reduce thermal resistance, improve device reliability, and optimize cooling performance.