Ball Screw Machining: Complete Guide to Process, End Machining & Hard Turning What is ball screw machining? Ball Screw Machining (also referred to as Ball Screw Maching) unlocks exceptional precision—a high-performance manufacturing process that uses precision-engineered ball bearings to convert rotary motion into smooth, reliable linear motion. First and foremost, this advanced ball screw machining […]

Archivos de Categoría: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

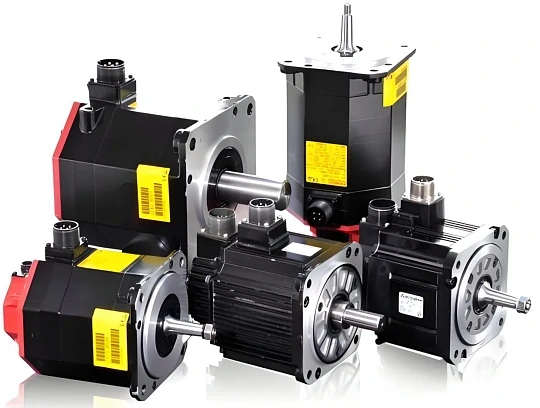

Complete Guide to Servo Motors: How They Work, Applications, and Precision CNC Housing Machining What is a Servo Motor? A servo motor operates through the principles of electromagnetism, where a generated energy field powers the rotor. Over time, continuous advancements have transformed these devices from auxiliary drives into reliable main drives for a wide range of industrial […]

Industrial Automation Supplier & Parts Solutions for Global Manufacturing What Are Industrial Automation Parts? Industrial automation parts encompass a broad range of electrical and electronic components designed to control, monitor, and automate machines, production lines, and industrial processes across factories, warehouses, and manufacturing plants. In today’s competitive manufacturing environment, businesses increasingly rely on industrial automation parts to […]

Tight Tolerance Machining: How to Achieve High-Precision CNC Parts What is Tight tolerance machining ? In modern manufacturing, machining tolerance refers to the allowable variation in a part’s physical dimensions, usually expressed as plus or minus values from the nominal size. When components are produced with extremely minimal deviation—often within thousandths of an inch or even microns—they are […]

Non-Standard Precision Parts: Materials, Processing, Applications & Supplier Guide What are Non-Standard Precision Parts? Non-standard parts are components without strict industry standards, with specifications primarily controlled by manufacturers or defined by customers. They can be broadly divided into metal and non-metal categories. Metal non-standard parts are typically made to customer drawings, with molds, tolerances, and […]

Precision CNC Machining of Precision Machined Shafts: Design, Materials, Processes & Applications What Are Machined Shafts? A machined shaft is a cylindrical mechanical component used to transmit torque and rotational motion between different machine parts. Typically made from metals such as steel, stainless steel, aluminum, or titanium, these shafts are manufactured using precision CNC machining […]

Which Bolt and Fastener Strengths Ensure Project Safety? What Are Bolt and Metal Fastener Strengths? When it comes to Industrial Bolt & Fastener Strengths, understanding the strength of industrial metal fasteners is essential for engineers, construction teams, and manufacturers. Whether you’re working with A325 bolts, high-strength structural bolts, or custom rivets, knowing the differences between […]

Which Brass Alloy is Best for Your CNC and Industrial Projects? What Metals Are in Brass and Why Should You Choose It? Brass is one of the most versatile metal alloys, mainly made of copper and zinc, sometimes with small amounts of lead, tin, iron, or nickel to enhance machinability, durability, and corrosion resistance. Its […]

What Are Specialty Fasteners? Engineers design specialty fasteners—screws, bolts, nuts, and fastening systems—for applications where standard fasteners cannot perform adequately.This category includes specialty bolts and screws, specialty nuts and bolts, captive fasteners, quarter-turn fasteners, thread inserts, and aerospace fasteners. You’ll commonly find them in aerospace, automotive, electronics, industrial equipment, and sheet metal assemblies, where safety […]

What Are the Benefits of Using Custom Bolts and Fasteners in Industrial Applications? What Are Custom Bolts and Custom Made Bolts Used For in Industrial Applications? Custom bolts and custom made bolts are essential when standard fasteners can’t meet performance, size, or material requirements. In industrial settings—like structural steel, heavy machinery, automotive assemblies, or energy […]