How to Paint, Refinish, and Protect Cast and Anodized Aluminum Like a Pro | Welleshaft

1.Introduction: Why Aluminum Painting & Finishing Matter

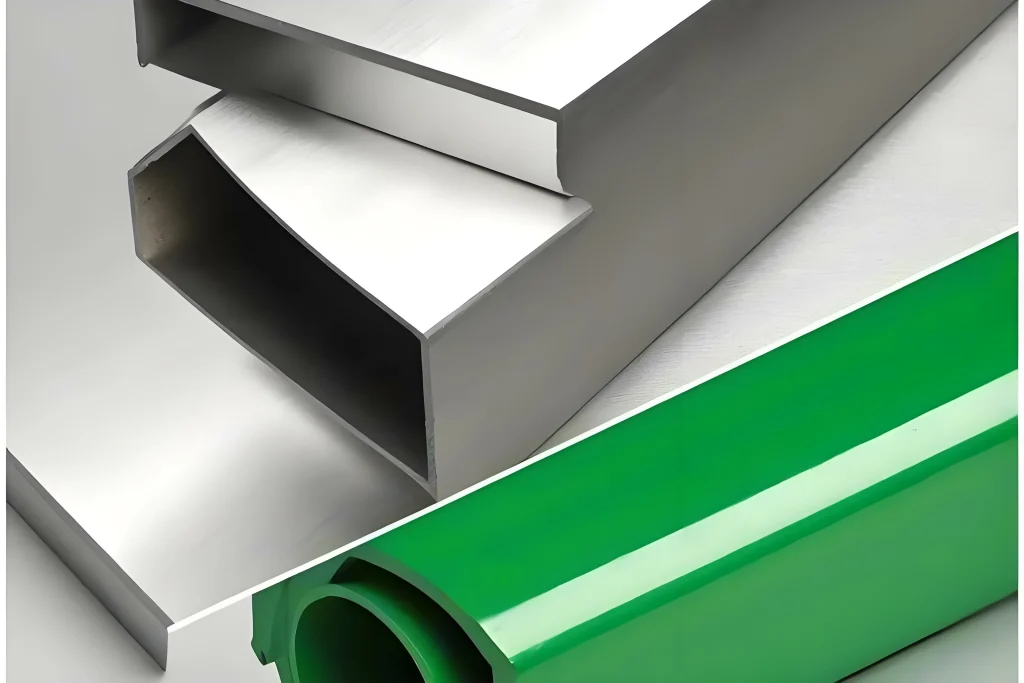

Aluminum—whether in cast or anodized form—is prized for its strength-to-weight ratio, corrosion resistance, and clean appearance. However, without proper surface preparation and high-quality materials, cast aluminum painting can fail prematurely, causing paint peeling, oxidation, and functional issues.

That’s why customers—from RV owners to manufacturers using Bonnell Aluminum extrusions—ask:

“Can you paint aluminum? What’s the best way to do it?”

In this guide, Welleshaft walks you through how to paint, restore, and refinish cast aluminum, anodized aluminum, and aluminum furniture, using the right techniques, tools, and coatings.

2.The Science Behind Aluminum Surface Finishing

(1)How Aluminum Painting Works

Aluminum’s surface naturally forms an oxide layer that resists paint adhesion. To ensure coating durability, it must be:

1.Degreased

2.Sanded or etched

3.Primed with an appropriate base

4.Coated with weather- and UV-resistant paint

Special processes are needed for anodized surfaces, such as etching primers, due to their hard, non-porous finish.

3.Welleshaft’s Surface Finishing Capabilities

At Welleshaft, we provide:

| Capacidad | Description |

| Cast Aluminum Refinishing | Including paint removal, sanding, coating, sealing |

| Anodized Surface Painting | With adhesion testing and primer treatment |

| CNC Aluminum Spray Coating | For electronic enclosures and industrial panels |

| Custom Extrusion Recoating | Including Bonnell Aluminum and AACOA profiles |

| Environmental Testing | Salt spray, UV, and durability validation |

| Touch-up & Restoration Services | For scratches, fading, or oxidized surfaces |

🛠️ Certified equipment includes salt spray chambers, adhesion testers, spray booths, and XRF analyzers for coating thickness validation.

4.Team Experience & Industry Certification

Our engineers and quality control team are certified in:

1.ISO 9001 Quality Management

2.ASTM D3359, D3363, and ISO 2409 coating adhesion tests

3.Powder Coating Institute (PCI) Certified Technicians

4.5+ years’ combined experience in RV, outdoor furniture, and automotive sectors

5.Process Walkthrough: Painting Aluminum, Step by Step

(1)Surface Prep

Degrease, sand, and apply etching primer.

(2)Choose Paint

For cast aluminum, use UV-stable epoxy or polyurethane. For anodized aluminum, use specialty bonding primers.

(3)Apply Coating

Spray or brush in thin coats. Wait for 24-48 hrs curing time.

(4)Topcoat Protection

Seal with clear enamel or powder coating.

✅ This applies to everything from cast patio chairs to anodized red wheels.

6.Painting Over Anodized Aluminum: What You Must Know

1.Can you paint over anodized aluminum without sanding? Yes, but etching primer is essential. Here’s how to paint anodized surfaces:

2.Degrease and scuff the anodized layer

3.Apply a self-etching primer

4.Spray with compatible anodized aluminum paint

5.Allow 48-hour curing for durability

This method works for red anodized wheels, anodized aluminum tubing, and black anodized architectural panels.

7.Frequently Asked Questions

(1)Can anodized aluminum be painted or powder coated?

Yes, but it requires etching primer and mechanical scuffing to ensure adhesion.

(2)How to repaint aluminum cabinets that are already painted?

Sand lightly, degrease, apply bonding primer, and recoat with spray enamel.

(3)Does cast aluminum rust if not painted?

It corrodes slowly via oxidation, which dulls appearance—paint adds long-term protection.

(4)What paint sticks best to brushed aluminum?

Acrylic enamel or epoxy-based paint offers strong adhesion. Avoid latex-based products.

(5)Can you polish painted aluminum without damage?

Yes, using non-abrasive aluminum polish. Avoid heavy polishing if the topcoat is thin or fading.

8.Anodized vs Painted vs Powder Coated Aluminum

| Feature | Anodizing | Painting | Powder Coating |

| Durability | ★★★★★★★★★☆ | ★★★★★★★☆☆☆ | ★★★★★★★★★★ |

| Color Variety | ★★★★☆☆☆☆☆☆ | ★★★★★★★★★☆ | ★★★★★★★★☆☆ |

| Surface Hardness | ★★★★★★★★★★ | ★★★★☆☆☆☆☆☆ | ★★★★★★★★★☆ |

| Cost Efficiency | ★★★★☆☆☆☆☆☆ | ★★★★★★★☆☆☆ | ★★★★★★★★☆☆ |

| Recommended For | Architectural Panels | Outdoor Furniture | Industrial Enclosures |

9.Customer Case Studies

1: Repainting Cast Aluminum Patio Furniture

Location: Arizona

Challenge: Peeling paint, UV damage

Solution: Sandblast, epoxy primer, polyurethane topcoat

Result: 5+ years of color retention

2: RV Exterior Refinishing

Client: Midwest RV Rental

Scope: Repainting aluminum side panels

Value: Increased customer satisfaction, no fading after 2 summers

10.Applications Across Industries

Residential: Patio furniture, fences, mailboxes

Automoción: Anodized wheels, aluminum hoods, CNC parts

Construction: Curtain walls, handrails, Bonnell extrusions

Electronics: Painted aluminum panels, enclosures

Recreation: Aluminum canoes, bike frames

11.Why Choose Welleshaft?

- In-house finishing & testing labs

- Proven track record with Bonnell Aluminum and AACOA components

- Fast turnaround times (72 hrs typical)

- Global client base from North America to Southeast Asia

- Local support teams with engineering background

12.Get Expert Help Today — Contact Welleshaft

Whether you’re a homeowner restoring cast aluminum patio furniture, a manufacturer repainting anodized aluminum extrusions, or an OEM needing CNC aluminum paint compatibility, Welleshaft is your trusted solution partner.