1.Bevel Gear Measurement and Metrology Services | Welleshaft

In modern industrial applications, precision is paramount. Bevel Gear Measurement and Metrology Services are essential for bevel gears manufacturing, custom bevel gear manufacturing, and precision bevel gear production, ensuring optimal performance, efficiency, and longevity. For high-torque or heavy-duty systems, even minor deviations in bevel gear dimensions can lead to noise, vibration, premature wear, or total mechanical failure. That’s why professional bevel gear measurement and metrology services for industrial use are a critical part of production and quality control. At Welleshaft, we provide comprehensive bevel gear inspection and metrology services for quality control, combining advanced tools and expert analysis to guarantee optimal results for spiral bevel gear manufacturing, straight bevel gear manufacturing, and CNC bevel gear production.

2.Why Bevel Gear Measurement is Critical

Bevel gears, including zerol bevel gear and spiral miter gears, are fundamental components in mechanical assemblies. Accurate bevel gear measurement solutions for mechanical engineering projects are crucial because:

- Ensuring Proper Gear Meshing and Load Distribution

1)Misaligned gears or incorrect tooth profiles can cause uneven load distribution, resulting in noise, vibration, and decreased service life.

2)High-precision bevel gear inspection service and bevel gear quality inspection can detect deviations before they cause system failures.

- Maintaining High Torque and Heavy-Duty Performance

1)Industrial machinery often operates under high torque conditions, which require precise engagement between bevel gear and pinion.

2)Accurate bevel gear measurement and calibration services for manufacturing prevent excessive wear and gear breakage.

- Quality Assurance in Production

1)For precision bevel gear production, especially in aerospace, automotive, or industrial applications, maintaining strict tolerance levels is mandatory.

2)High-precision bevel gear inspection and measurement services allow manufacturers to meet stringent industry standards consistently.

3.Common Challenges in Bevel Gear Measurement

Despite its importance, bevel gear metrology can be complex due to several factors:

- Complex Geometry

1)Bevel gears have conical shapes, variable tooth profiles, and spiral angles in the case of spiral gears.

2)Standard calipers or micrometers are insufficient for accurate measurement, making advanced CNC bevel gear measurement services for accuracy and performance essential.

- High Accuracy Requirements

1)Small deviations can compromise gear meshing, especially in high-torque applications.

2)Precision measurement ensures that industrial bevel gear inspection meets required tolerances.

- Material and Surface Variability

1)Hardness, finishing, and coatings can affect measurements.

2)Metrology tools must accommodate bevel gear machining services variations and surface treatments.

- Time and Resource Constraints

1)Traditional measurement methods are labor-intensive.

2)Outsourcing to professional bevel gear measurement and calibration services for manufacturing can save time while increasing accuracy.

4.Bevel Gear Measurement Process

Welleshaft follows a structured bevel gear measurement and metrology workflow:

(1)Initial Inspection

Visual checks for cracks, wear, or chipping in straight bevel gears and spiral miter gears.

Verification of tooth geometry against design specifications.

(2)Dimensional Measurement

Using CNC bevel gear production measurement tools, including coordinate measuring machines (CMM), laser scanners, and gear analyzers.

Critical parameters: pitch diameter, tooth thickness, pressure angle, spiral angle, and root/face relief.

(3)Surface and Finish Evaluation

Assess surface roughness and profile deviations, which can affect gear efficiency.

High-precision bevel gear metrology for heavy-duty and high-torque systems ensures performance in demanding applications.

(4)Calibration and Verification

Compare measured data against CAD models or standards.

Generate reports for bevel gear inspection and metrology services for quality control.

Recommend corrective actions if deviations are detected.

(5)Preventive Recommendations

Define inspection intervals for bevel gear measurement solutions for mechanical engineering projects.

Suggest maintenance and refurbishment strategies to extend gear life.

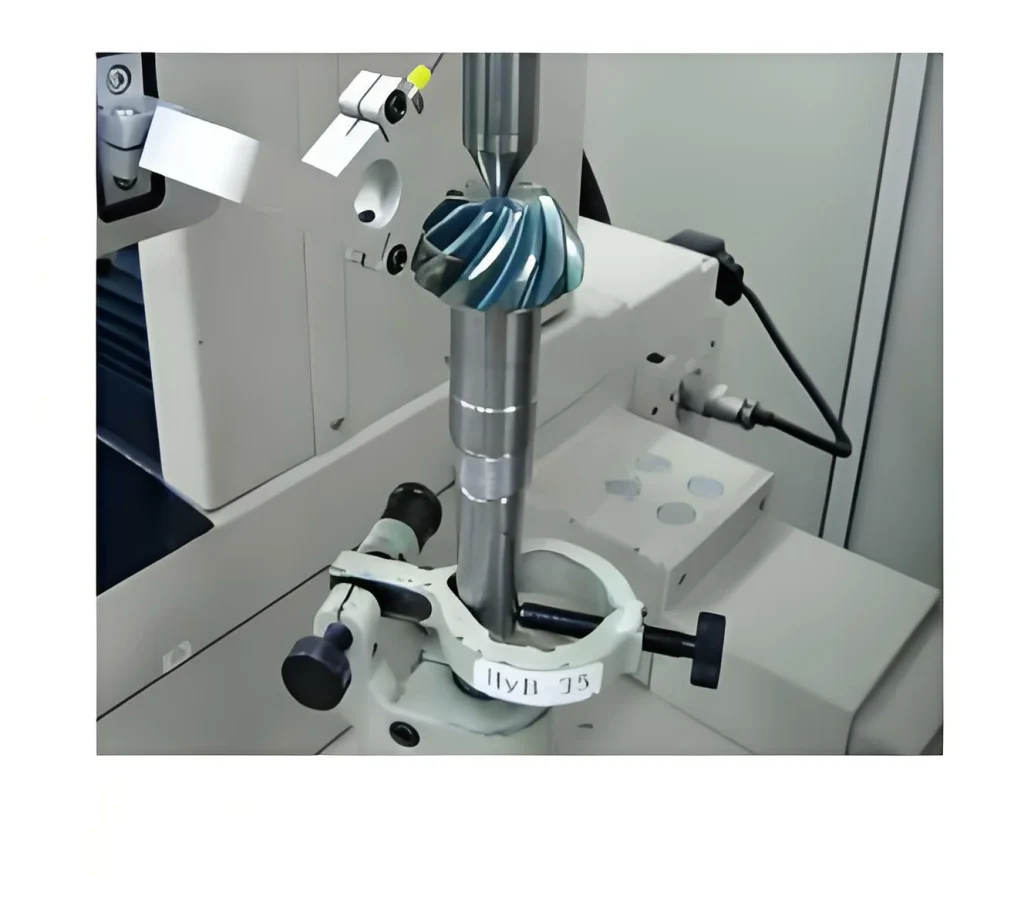

5.Tools and Technologies for Bevel Gear Metrology

Professional bevel gear testing and metrology services for quality assurance rely on advanced equipment:

- Coordinate Measuring Machines (CMM)– for high-accuracy 3D measurements

- Gear Measuring Centers– specialized for bevel gear and pinion inspection

- Laser Scanners & Optical Profilometers– non-contact measurement for complex geometries

- Hardness and Surface Roughness Testers– ensuring material integrity and surface quality

These tools ensure precise measurements for bevel gear machining services, custom bevel gear manufacturing, and precision bevel gear production.

7.Frequently Asked Questions

(1)What is bevel gear metrology and why is it important?

It’s the science of measuring gear geometry and accuracy to ensure proper operation, prevent failure, and maintain high-torque performance.

(2)How do you measure bevel gears for accuracy in manufacturing?

Using CMM, gear analyzers, laser scanning, and surface profiling to capture all critical dimensions.

(3)What are the best tools for bevel gear measurement and calibration?

Coordinate Measuring Machines, Gear Measuring Centers, Optical Profilometers, and Hardness Testers.

(4)How do bevel gear measurement services ensure precision in high-torque applications?

By detecting misalignment, tooth deviations, and surface inconsistencies, allowing corrective action before operation.

(5)How often should industrial bevel gears be measured and inspected?

Inspection frequency depends on load, usage, and operational environment but typically ranges from quarterly to annually for high-precision systems.

Welleshaft is a professional industrial gear inspection and repair provider with over 10 years of experience in bevel gear measurement and metrology services for industrial use, precision bevel gear measurement for high-accuracy applications, and bevel gear inspection and metrology services for quality control. Our engineers specialize in troubleshooting, inspection, calibration, and performance optimization of bevel gears to ensure maximum reliability and operational efficiency.