1.Bevel Gears Custom for Industrial Applications

In modern industrial operations, robotics, and heavy machinery, standard bevel gears often cannot meet unique performance requirements. Customers seeking custom bevel gear manufacturing, precision bevel gear production, and spiral bevel gear manufacturing frequently face challenges finding reliable solutions. Welleshaft offers comprehensive bevel gears manufacturing services, CNC bevel gear production, and industrial bevel gear inspection to ensure every bevel gear and pinion meets stringent specifications. From straight bevel gears to Zerol bevel gear and hypoid gear manufacturing, our custom-made bevel gears support heavy machinery, robotics systems, and specialized industrial equipment. Using advanced bevel gear machining services, gear measurement and inspection, and bevel gear quality inspection, Welleshaft delivers high-performance, durable custom bevel gears for heavy machinery applications and tailored bevel gears for industrial use and automation, helping clients overcome challenges in finding precise, reliable solutions for their specialized gear needs.

2.Why Custom Bevel Gears Are Essential

Off-the-shelf bevel gears often fail to provide the required:

1.Torque handling for high-load applications

2.Precision for robotic or automated systems

3.Durability for specialized machinery or harsh environments

Without professional custom bevel gear solutions for mining and construction industries or high-quality custom bevel gears for robotics systems, clients risk premature wear, noise, reduced efficiency, and costly downtime. By opting for custom bevel gear manufacturing for specialized industrial needs, engineers can:

1.Optimize gear ratio, tooth profile, and backlash

2.Select appropriate materials for wear resistance and heat treatment

3.Ensure compatibility in complex bevel gear assembly systems

Welleshaft’s precision gear fabrication guarantees that bespoke bevel gears for manufacturing and industrial systems meet stringent industrial requirements.

3.Step-by-Step Process for Custom Bevel Gear Manufacturing

1. Requirement Analysis and Design

The first step in custom bevel gear manufacturing involves understanding the client’s specific industrial application. Welleshaft engineers evaluate:

1.Torque and speed requirements

2.Load capacity and operational cycles

3.Environmental conditions, including temperature and lubrication

4.Compatibility with straight bevel gears, spiral bevel gear production, or Zerol/zero bevel gear

Using CAD/CAM modeling, engineers simulate bevel gear and pinion assemblies, spiral miter gears, and conical gear manufacturing to ensure optimal performance and durability.

2. Material Selection and Preparation

Selecting the right materials is critical for precision bevel gear production. Welleshaft considers:

1.Alloy steels for high-torque industrial applications

2.Stainless steel for corrosion resistance in marine or chemical environments

3.Surface treatment and heat treatment to enhance wear resistance

Proper material preparation is essential for CNC precision bevel gears for custom industrial machinery and affordable custom bevel gears for high-torque industrial systems.

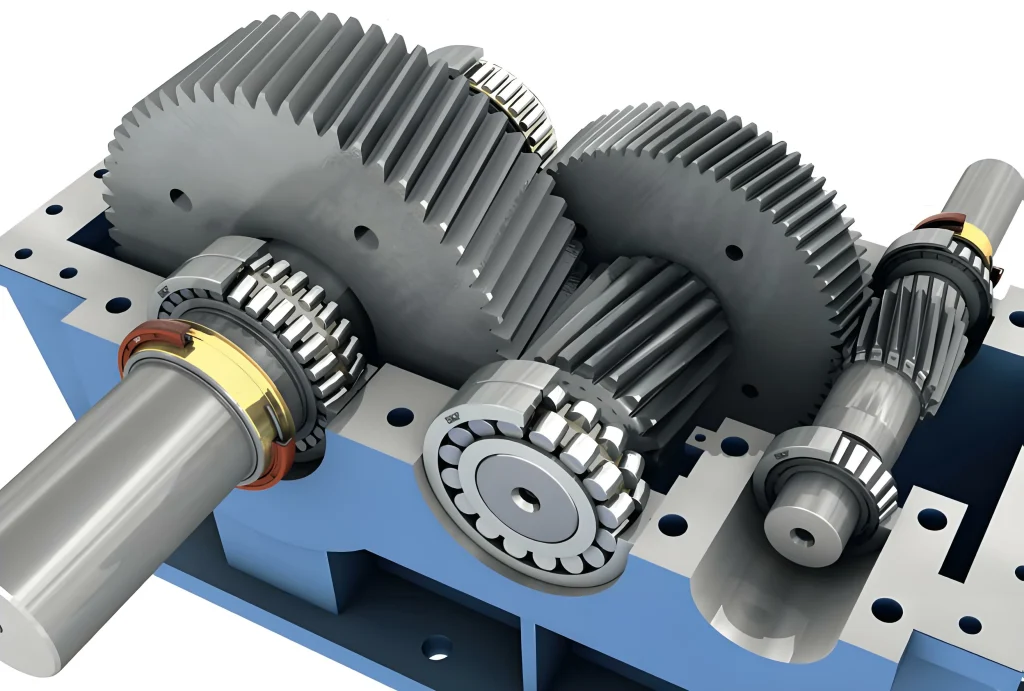

3. Precision Machining and Fabrication

Welleshaft employs advanced bevel gear machining services to produce custom-made bevel gears with tight tolerances. This step includes:

1.CNC bevel gear production for high repeatability and precision

2.Gear hobbing, shaping, grinding, and finishing

3.Specialized processes for spiral bevel gear manufacturing, straight bevel gear manufacturing, and hypoid gear manufacturing

Each gear undergoes rigorous dimensional checks, ensuring high-quality custom bevel gear solutions for heavy-duty industrial applications.

4. Inspection and Quality Assurance

Every gear is subject to detailed bevel gear inspection service and gear measurement and inspection. Welleshaft’s process ensures:

1.Tooth profile accuracy

2.Backlash and pitch verification

3.Surface finish quality

4.Overall dimensional tolerance compliance

Using bevel gear inspection for industrial applications, gear inspection and calibration, and bevel gear quality assurance services, clients receive confidence in precision bevel gears for automotive and industrial machinery applications.

5. Assembly and Functional Testing

Once individual gears are manufactured, bevel gear assembly and functional testing are conducted to:

1.Validate spiral miter gears and straight bevel gears alignment

2.Ensure smooth torque transfer under operational loads

3.Test custom bevel gears for heavy machinery applications in simulated conditions

Functional verification ensures that custom bevel gear solutions for mining, construction, or robotics systems perform reliably in real-world applications.

4.Industries Benefiting from Custom Bevel Gears

| Industry | Gear Type | Key Focus |

| Automoción | Spiral / Hypoid | Gearboxes, differential drives |

| Robotics | Straight / Spiral | Precision movement, minimal backlash |

| Marine | Spiral / Zerol | Propulsion and steering systems |

| Heavy Machinery | Straight / Conical | High-load torque transfer, durability |

| Mining & Construction | Spiral / Straight | High-torque industrial systems |

Professional bevel gear inspection and testing ensures every custom bevel gear manufacturing for specialized industrial needs meets operational and safety standards.

5.Benefits of Custom Bevel Gears Over Standard Gears

1.Tailored performance for precision bevel gears for industrial use and automation

2.Increased lifespan and reduced maintenance costs

3.Optimized efficiency in robotics systems and heavy machinery

4.Improved torque transmission and smoother operation

Choosing bespoke bevel gears for manufacturing and industrial systems ensures maximum operational reliability, especially for custom bevel gear solutions for mining and construction industries or high-quality custom bevel gears for robotics systems.

6.How to Choose a Custom Bevel Gear Manufacturer

When selecting a provider, consider:

1.Experience in high-precision bevel gear manufacturing

2.Capabilities in CNC bevel gear production and industrial bevel gear inspection

3.Proven track record with custom bevel gear manufacturing for specialized industrial needs

4.Ability to provide bevel gear quality assurance services and functional testing

Welleshaft combines all these services to deliver tailored bevel gears for industrial use and automation with reliable performance and durability.

Lead Engineer at Welleshaft with over 5 years of experience in custom bevel gear manufacturing, precision bevel gear production, and bevel gear inspection services. Specializes in tailored bevel gears for industrial use and automation, high-quality custom bevel gears for robotics systems, and bespoke bevel gears for manufacturing and industrial systems.