1.Best Practices for HiPot Testing of Busbars | Welleshaft

High potential testing (commonly known as HiPot testing) is a vital electrical safety procedure used to validate insulation integrity in various electrical components. At Welleshaft, we implement best practices in HiPot testing to ensure our busbars and related systems meet rigorous international safety standards. This guide explores what is HiPot testing, why it’s essential, and how it’s applied in industrial and medical sectors.

2.What Is HiPot Testing?

HiPot testing—short for “high potential testing”—involves applying a high voltage to a device to confirm the insulation between conductive parts is effective. It ensures no current flows through insulation that should remain intact. Commonly used in high-voltage equipment like transformers, PCBs, and switchgear, this test is a fundamental safety check in electrical engineering.

(1)Why HiPot Testing Matters

Ensures electrical isolation in high-voltage systems

Prevents breakdowns and failures in field applications

Confirms that laminated busbars have sufficient insulation between conductive layers

Mitigates fire and shock risks in power distribution

3.People Also Ask

1.What does “hipotted” mean?

“Hipotted” refers to an electrical component that has passed a HiPot test, verifying its insulation quality under high voltage. It reflects hipotted meaning in industrial testing.

2.What is the difference between a HiPot test and a Megger test?

A HiPot test checks insulation under high stress (voltage), while a Megger test measures insulation resistance at lower voltages. This difference is crucial in understanding hypo test vs megger test in electronics.

3.Is HiPot testing required for medical devices?

Yes. IEC 60601 mandates HiPot testing for Class II medical equipment to ensure patient safety

4.Types of HiPot Tests Used in Busbar Applications

Welleshaft applies multiple methods of HiPot testing based on application and component type:

(1)DC HiPot Testing

Uses direct current to apply high voltage

Ideal for systems with capacitive loads like cable harnesses

Often used in highpot test for cable harness quality control

(2)AC HiPot Testing

Applies alternating current

Simulates real operating conditions in transformers and hipotted motors for industrial automation

(3)Surge Testing

Stress test with rapid voltage rise

Detects weak spots in insulation before failure

Suitable for hipotted definition in transformer testing

(4)Insulation Resistance Testing

Measures the resistance between conductors and ground

Often used before performing a full HiPot test

(5)Partial Discharge Testing

Identifies minuscule insulation breakdowns

Critical for quality assurance in HV equipment acceptance

(6)Visual & Physical Inspection

Initial step in spotting mechanical flaws before testing

Supports industrial safety compliance hipot test

5. HiPot Testing Applications in Different Industries

Electrical Engineering & Power Distribution

Insulation verification plays a vital role in electrical engineering by checking the integrity between conductive components. Engineers use high voltage to confirm that busbars, wires, and terminals are properly isolated, reducing the risk of leakage or short circuits.

(1)Electronics Manufacturing

HiPot testing in electronics focuses on components like PCBs and cable harnesses:

Highpot test for cable harness quality control identifies early-stage insulation issues.

Real-time HiPot test automation solutions streamline production by delivering fast, repeatable insulation testing for every unit on the line.

Adheres to IEC standards for hipot test in electronics

(2)Industrial and Heavy Machinery

Industrial safety depends on proper insulation in high-power components:

Hipotted definition in transformer testing ensures field durability.

Benefits of hipotted components in heavy machinery include extended operational lifespan and reduced downtime.

Hypo test in factory acceptance testing is commonly used before dispatch to detect insulation weaknesses.

Helps with hipot test for switchgear manufacturing in compliance with industry codes.

(3)Medical Devices and Healthcare

What is hypo test in medical device QC? It’s the high-voltage test verifying that insulation won’t break down.

IEC 60601 hipot test standard for medical devices governs Class II safety.

Hipotted patient-connected devices compliance protects users from electrical faults.

Highpot test in ECG machine validation is a standard requirement.

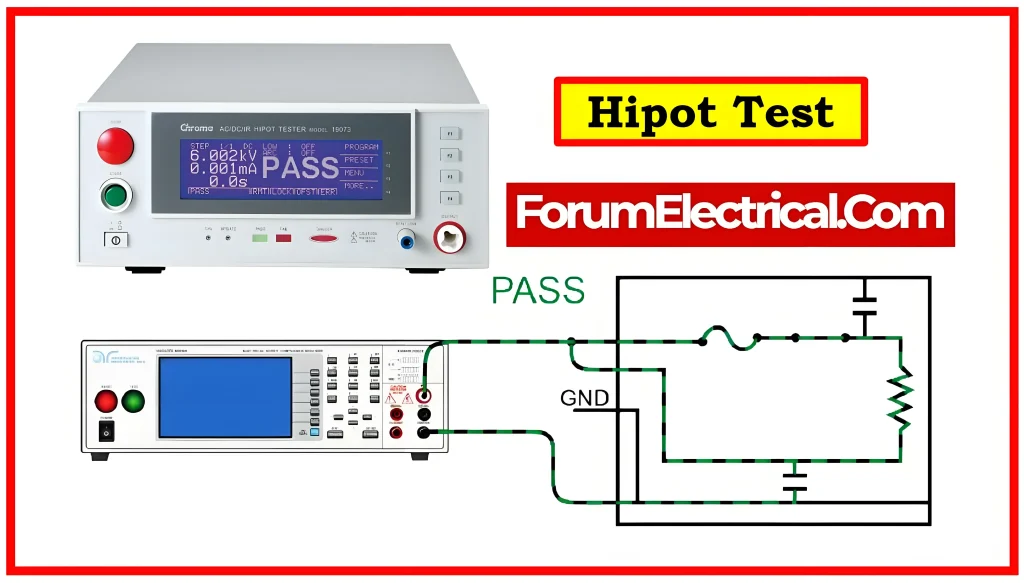

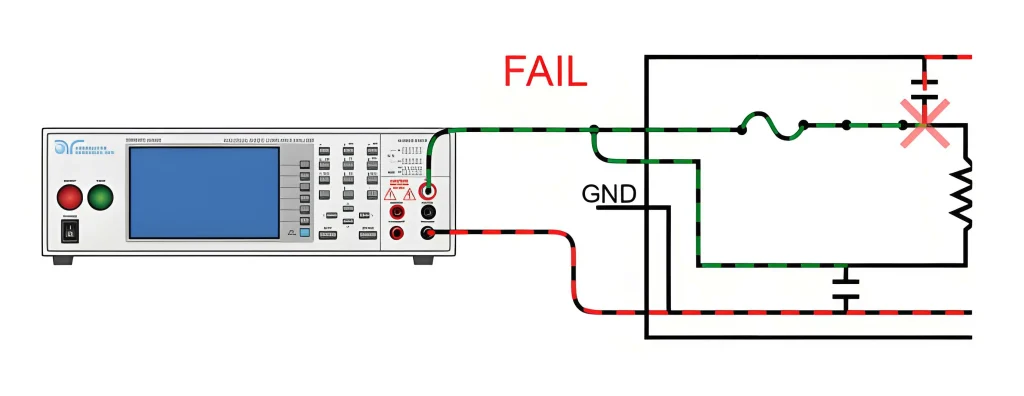

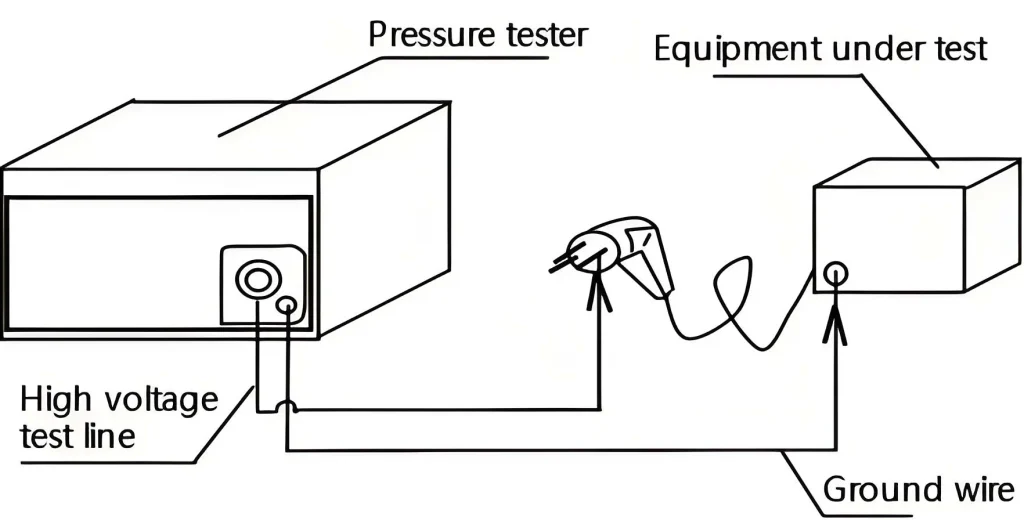

6.How Is a HiPot Test Performed?

The HiPot test procedure involves the following steps:

Device Setup – One conductor is energized, and adjacent conductors are grounded.

Voltage Application – A test voltage (typically 2x operating voltage + 1,000V) is applied.

Leakage Monitoring – The current flow is monitored to detect breakdown.

Pass/Fail Analysis – If current stays below a threshold, the device is considered “hipotted.”

7. HiPot Testing Voltage Guidelines

| Equipment Type | Typical Operating Voltage | HiPot Test Voltage |

| PCB Assembly | 24–48V | 1,500–2,000V DC |

| Busbars | 600V | 2,200V AC |

| Switchgear | 11kV | 30kV AC or DC |

| Medical Devices (Class II) | 250V | 1,500–3,000V per IEC 60601 |

| Cable Harnesses | 100–300V | 1,000–2,500V |

8.Industry Standards and Compliance

To ensure safe and compliant testing, Welleshaft follows:

IEC standards for HiPot test in electronics

UL and CSA compliance for North America

British standards: what does hipotted mean in British manufacturing

9.Choosing the Best HiPot Testing Equipment

Whether you’re a manufacturer or OEM, selecting the best HiPot testers for contract manufacturers or in-house labs is key. Welleshaft recommends:

Programmable voltage ramping and shutdown

Leakage current threshold customization

Data logging for traceability

Safety interlocks and operator protection

10.Conclusion: Why Choose Welleshaft for HiPot Testing?

At Welleshaft, we combine deep industry experience with advanced testing technology to ensure your components meet all insulation and safety requirements. From PCB assemblies to heavy-duty switchgear, our testing protocols help you stay compliant and confident.