Industrial Automation Supplier & Parts Solutions for Global Manufacturing

What Are Industrial Automation Parts?

Industrial automation parts encompass a broad range of electrical and electronic components designed to control, monitor, and automate machines, production lines, and industrial processes across factories, warehouses, and manufacturing plants.

In today’s competitive manufacturing environment, businesses increasingly rely on industrial automation parts to streamline operations and reduce dependency on manual labor. As a result, these components play a critical role in helping manufacturers improve process consistency, enhance workplace safety, and significantly increase production output—all while maintaining stable performance.

Moreover, when integrated into a complete automation system, these parts work together to ensure continuous, uninterrupted operation. This is especially important because many automation components must operate 24/7 under harsh industrial conditions, such as extreme temperatures, vibration, dust, or electrical interference.

Ultimately, selecting the right automation equipment parts not only improves operational efficiency but also minimizes downtime, protects capital investment, and supports long-term production scalability.

Automation Components: What Are the Key Categories?

Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs) function as the central control unit of modern automation systems. In practice, they execute pre-programmed logic to coordinate machines, manage process sequences, and ensure stable operation across production lines.

As automation becomes more complex, manufacturers increasingly depend on PLCs to deliver reliability, fast response times, and scalable control architecture—making them a critical investment for long-term system performance.

Human Machine Interfaces (HMIs)

Human Machine Interfaces (HMIs) enable operators to interact directly with automated equipment. Through intuitive touchscreens, users can monitor real-time operating data, respond to alarms, and adjust system parameters instantly.

More importantly, well-designed HMIs reduce operator error, improve response speed, and enhance overall production visibility—especially in high-volume or multi-shift operations.

Servo Drives and Motors

When precision matters, servo drives and motors become essential. These components control accurate motion in applications such as robotics, CNC machines, packaging lines, and automated conveyors.

Because they deliver high torque, fast acceleration, and repeatable positioning, servo systems directly support productivity, product consistency, and equipment longevity.

Variable Frequency Drives (VFDs)

Variable Frequency Drives (VFDs) regulate motor speed and torque based on actual load demand. As a result, they significantly improve energy efficiency while reducing mechanical stress on motors.

Consequently, industries commonly deploy VFDs in fans, pumps, mixers, and elevators to lower operating costs and extend equipment service life.

Sensors and Encoders

Sensors detect parameters like presence, temperature, pressure, and motion, while encoders provide real-time feedback on motor position and speed—both essential for precise, high-quality automation.

I/O Modules and Power Supplies

I/O modules transmit data between devices and controllers, while power supplies ensure stable voltage, preventing downtime and equipment failure.

Reliable Automation Parts: Why Are They Important?

Investing in high-quality industrial automation parts helps manufacturers proactively avoid a wide range of operational risks. More importantly, reliable components directly protect production continuity and profitability.

Specifically, premium industrial automation components help prevent:

- Costly unplanned downtimethat disrupts production schedules

- Unexpected maintenancecaused by premature part failure

- Workplace safety incidentslinked to unstable or incompatible components

- Revenue loss from inefficient operationsand reduced output

Moreover, sourcing the right automation equipment part—with the correct specifications, certifications, and part number—can ultimately determine whether a production line operates efficiently or fails under pressure.

Therefore, businesses that prioritize performance, safety, and long-term cost control increasingly choose to work with experienced automation parts sourcing specialists who understand technical requirements, compatibility risks, and supply chain reliability.

Industries Using Industrial Automation Parts: Which Ones Rely on Them?

Today, industrial automation parts play a vital role across a wide range of production-driven industries. As manufacturers pursue higher efficiency and consistent quality, they increasingly rely on automation equipment parts to support scalable, data-driven operations.

In practice, automation parts are widely deployed in:

- Automotive manufacturing, where precision and repeatability are critical

- Food and beverage processing, which demands hygiene, speed, and consistency

- Packaging and logistics, where throughput and uptime directly affect delivery performance

- Pharmaceuticals and life sciences, requiring controlled, validated processes

- Energy and utilities, where reliability and safety are non-negotiable

- Building materials and construction, supporting heavy-duty, continuous operations

Ultimately, industrial automation components power everything from high-speed conveyor systems to advanced robotic arms. By reducing manual intervention and human error, these components ensure stable output, predictable performance, and long-term operational efficiency.

Automation Technology Trends

As Industry 4.0 continues to reshape modern manufacturing, industrial automation components are rapidly evolving to meet higher performance and connectivity demands. Consequently, businesses that invest in advanced automation equipment parts gain a measurable competitive advantage.

Today’s automation components are increasingly:

- Smarter and IIoT-ready, enabling real-time data collection and remote monitoring

- More compact and energy-efficient, helping reduce energy consumption and cabinet space

- Easier to integrate with software and cloud platforms, supporting digital manufacturing strategies

- Safer and more secure, with built-in diagnostics, predictive maintenance features, and cybersecurity protections

As a result, keeping automation parts up to date does more than modernize equipment. It actively improves productivity, minimizes material waste, reduces unplanned downtime, and helps manufacturers remain competitive in fast-changing global markets.

How Should Buyers Prepare?

Mapping System Requirements Before Automation Parts Sourcing

Before reaching out to suppliers, buyers should clearly define their automation system requirements. This includes voltage ranges, load fluctuations, control architecture, communication protocols, and operating environments.

By establishing precise technical parameters early, procurement teams enable industrial automation parts sourcing specialists to recommend fully compatible components—rather than risky, generic substitutes.

As a result, new buyers significantly reduce the likelihood of mismatched automation equipment parts that often lead to inefficiency, unstable performance, or premature component failure.

Why Power Conditions Directly Impact Automation Performance

All industrial automation equipment relies on stable electrical input to function reliably. However, voltage dips, spikes, harmonic distortion, and electrical noise frequently affect motors, drives, and controllers.

Consequently, poor power conditions increase energy loss, accelerate wear, and shorten the service life of critical automation components.

By understanding power behavior in advance, buyers can select suitable control devices from qualified industrial automation suppliers that support long-term operational stability and reduced maintenance costs.

Understanding Power Quality in Automation Systems

Power quality refers to how stable, clean, and balanced electrical power is before it reaches automation equipment. When power quality drops, systems often suffer from overheating, signal interference, and unexpected shutdowns.

Key considerations include:

- Stable voltageallows motors and drives to operate efficiently and consistently

- Clean powerprotects sensors, PLCs, and controllers from false signals and data errors

- Balanced electrical loadsreduce unnecessary energy loss across the automation system

Therefore, prioritizing power quality is essential when sourcing reliable industrial automation components.

Managing Spare Parts Availability and Lifecycle Planning

Modern automation systems require long-term support well beyond initial installation. Spare parts must remain available throughout the entire system lifecycle, including post-installation and end-of-life phases.

For this reason, buyers increasingly favor industrial automation parts suppliers that provide clear lifecycle planning, replacement strategies, and backward-compatible alternatives.

With proper lifecycle management in place, businesses minimize downtime, avoid forced upgrades, and maintain production continuity even when components become obsolete.

Supporting Customization and Market Flexibility

Customization capabilities play a growing role in automation equipment sourcing. OEM and ODM services allow products to be adapted to regional regulations, branding requirements, packaging standards, and technical specifications.

At the same time, flexible production models support both low-volume pilot projects and high-volume supply contracts.

As a result, distributors and system integrators gain greater market flexibility—allowing them to stay competitive without carrying excessive inventory or increasing financial risk.

What Should Manufacturers Consider?

What an Automation Supplier Actually Delivers Beyond Parts

A professional automation supplier provides far more than individual components. In practice, they support the entire industrial automation supply process by integrating product selection, logistics coordination, documentation, and technical support into a single sourcing workflow.

As automation systems become more interconnected, this role becomes increasingly critical. Experienced industrial automation suppliers understand how power stability, component compatibility, and supply continuity directly impact uptime, production output, and operational risk.

Evaluating Technical Compatibility Before Committing to a Supplier

Technical compatibility should always come before price discussions. Qualified suppliers clearly explain how their industrial automation components fit into your system architecture, including voltage ranges, communication protocols, environmental ratings, and load tolerance.

More importantly, a capable automation components supplier demonstrates how parts interact under real operating conditions—rather than relying on generic specifications or sales-driven recommendations.

Pricing Transparency and Effective Cost Control

Transparent pricing enables accurate budgeting and margin protection. Reliable industrial automation parts suppliers openly explain price variations based on availability, sourcing region, lead time, and order volume.

In contrast, suppliers who cannot clearly justify cost structures often expose buyers and distributors to unexpected expenses. Therefore, pricing clarity plays a key role in sustainable automation parts sourcing strategies.

Logistics Speed and Inventory Accessibility

When unplanned downtime occurs, delivery speed becomes a decisive factor. Suppliers with global inventory access and regional warehouses significantly reduce shipping time and customs delays.

As a result, buyers gain faster response capability without increasing local inventory pressure. For distributors, access to regional automation parts stock improves service reliability while maintaining cash-flow efficiency.

Avoiding Common Automation Supplier Selection Pitfalls

One of the most common sourcing mistakes is selecting suppliers based solely on price. Equally risky is overlooking electrical compatibility between components or ignoring documentation and traceability requirements.

A balanced evaluation—covering technical fit, sourcing reliability, and compliance—helps buyers avoid these costly errors and build a more resilient industrial automation supply chain.

Ensuring Product Authenticity Across Global Supply Chains

Product authenticity directly affects system safety, regulatory compliance, and long-term performance. Unauthorized or unverified automation parts frequently fail early or operate outside specified parameters.

For this reason, reputable industrial automation parts suppliers provide clear origin verification, traceable documentation, and consistent sourcing records. This approach significantly reduces technical risk and builds long-term buyer confidence.

Why Supply Chain Integration Matters in Automation Sourcing

An integrated industrial automation supply chain minimizes delays, stabilizes costs, and improves responsiveness to demand changes. Suppliers with multi-region inventory and coordinated logistics can react faster to both urgent replacements and planned expansions.

Consequently, distributors benefit from lower inventory pressure while delivering more reliable service across projects and markets.

Adapting Automation Sourcing Strategies to Regional Markets

Different regions require different sourcing strategies. For example, Southeast Asian markets often prioritize price comparison, flexible order volumes, and fast availability.

Meanwhile, European buyers place greater emphasis on product authenticity, regulatory compliance, and documentation accuracy.

Understanding these regional differences allows buyers to optimize automation equipment sourcing without compromising system integrity.

Evaluating Product Range and System Coverage

A broad and well-structured industrial automation product range simplifies procurement across multiple projects. Comprehensive coverage allows buyers to match components without mixing incompatible brands or platforms.

When automation supplies include motors, drives, breakers, PLCs, sensors, and control accessories within a unified portfolio, system consistency improves and long-term maintenance planning becomes far more efficient.

How Does the Market for Automation Parts Look?

OEMs vs. Independent Distributors in Automation Parts Sourcing

Before selecting specific suppliers, buyers must first understand the two dominant channels in automation equipment parts sourcing. In reality, many costly purchasing mistakes occur because buyers choose the wrong channel for the wrong situation.

Aligning the supplier type with the actual sourcing scenario is the foundation of an efficient and low-risk industrial automation supply strategy.

Original Equipment Manufacturers (OEMs)

Original Equipment Manufacturers (OEMs) design, engineer, and manufacture industrial automation components directly. As a result, they control product architecture, technology roadmaps, and pricing for large-scale projects.

Core Value of OEMs

- Strong technical authorityand system-level expertise

- Ability to deliver custom automation solutions

- Pricing leverage for high-volume, long-term contracts

Best Use Cases for OEM Sourcing

- Greenfield projects: When building a production line from scratch and requiring OEM engineers to design the system architecture using PLCs and advanced automation platforms

- Global standardization: When enterprises standardize on a single brand across multiple factories to simplify training, maintenance, and spare parts management

- High-volume machine building: When annual demand reaches hundreds or thousands of identical components, such as servo motors or drives

Independent & Authorized Distributors

Independent and authorized distributors act as the operational bridge between OEM factories and end users. More importantly, they focus on speed, availability, and brand diversity.

Core Value of Distributors

- Fast deliveryand same-day shipping capabilities

- One-stop sourcingacross multiple brands

- Access to deep and diversified inventory

Best Use Cases for Distributor Sourcing

- MRO and emergency maintenance: When a sensor or drive fails and immediate replacement is required

- High-mix, low-volume procurement: When sourcing PLCs, connectors, cables, and power supplies from different brands in a single order

- Urgent supply shortages: When OEM lead times extend to weeks or months, but distributors maintain reserved stock

Quick Comparison: Which Supplier Channel Fits Your Needs?

| Supplier Category | Typical Cost | Delivery Speed | Primary Strength | Typical Use Case |

| Global OEMs | $$$$$ | Slow (Production Lead Time) | Advanced technology & system integration | New system design, standardization |

| Authorized Distributors | $$$$ | Very Fast (Same-Day Shipping) | One-stop sourcing & deep inventory | MRO, urgent downtime |

| Cost-Effective Alternatives | $$ | Medium (Sea / Direct Freight) | High price-performance ratio | Planned production, budget control |

| Surplus & Obsolete Specialists | $$$ | Fast (In Stock) | Supporting EOL systems | Obsolete or hard-to-find parts |

Key Factors for Evaluating Automation Parts Partners

Once buyers understand the supplier landscape, the next step is selecting the right partner for each project. A practical approach is the LEAD Model, which balances speed, cost, engineering support, authenticity, and inventory depth.

LEAD Model Overview

| LEAD Factor | Key Priority | Purchasing Scenario | Recommended Supplier Channel |

| L – Lead Time | Speed / MRO | Emergency downtime & repair | Authorized distributors or surplus specialists |

| L – Cost | Budget control | Planned production / high volume | Cost-effective alternatives or OEMs |

| E – Engineering | Technical expertise | New system design / complex integration | Global OEMs |

| A – Authenticity | Trust & compliance | Obsolete parts / safety-critical systems | OEMs or surplus specialists with warranty |

| D – Inventory | Availability & variety | High-mix low-volume / BOM consolidation | Authorized distributors or component supermarkets |

Balancing Lead Time and Cost

In automation parts sourcing, speed and cost rarely align perfectly.

- Emergency downtime: When production stops, delivery speed outweighs cost. Air freight and in-stock suppliers minimize losses.

- Planned production: When timelines allow, direct sourcing and sea freight reduce BOM costs by 30–50%.

Evaluating Engineering Support Capability

For high-end industrial automation systems, buyers must confirm access to certified engineers who can support configuration and commissioning.

For standardized components, complete datasheets, documentation, and technical clarity often matter more than advanced engineering services.

Verifying Authenticity and Warranty Coverage

When sourcing obsolete automation parts, warranty policies and test reports are essential risk controls.

For new brands, certification systems such as CE or UL provide a fast and reliable authenticity check.

Assessing Real Inventory Depth

Finally, buyers should never rely solely on “in stock” labels. Instead, they should verify whether the inventory is real physical stock or merely virtual availability.

Suppliers that depend on back-to-back ordering introduce uncontrollable lead-time risks—especially during global supply disruptions.

Why This Matters for Automation Equipment Parts Sourcing

By matching sourcing channels with project needs and applying a structured evaluation model, buyers dramatically reduce downtime risk, cost overruns, and system incompatibility—while improving long-term supply chain resilience.

Sourcing Automation Equipment from China: Why Is It Popular?

Why Chinese Automation Systems and Equipment Are Driving Global Demand

The rapid growth of global industries has fueled a surge in demand for industrial automation systems and equipment. These automation solutions enhance productivity, reduce operational costs, and improve product quality across manufacturing, logistics, automotive, and electronics sectors.

Among global exporters, China’s automation systems and equipment occupy a strategic position, offering cost-effective, reliable, and increasingly sophisticated industrial automation components. Key exported products include robotic arms, conveyor systems, PLCs, sensors, and smart controllers, widely adopted in factories, warehouses, and production lines worldwide.

For distributors, repair centers, and manufacturers seeking to maintain a competitive edge, importing automation equipment from China presents a practical and scalable solution.

Main Chinese Automation Systems and Equipment for Export

China supplies a diverse range of industrial automation equipment suitable for multiple industries. The most prominent categories include:

Sensors and Actuators

China is a leading global supplier of sensors and actuators, essential for precise and efficient factory operations. These components are widely used in manufacturing, automotive, and electronics industries. Top exported products include:

- Proximity sensors

- Temperature sensors

- Pressure sensors

- Motion detectors

- Pneumatic actuators

- Hydraulic actuators

- Electric actuators

Conveyor and Sorting Systems

Chinese conveyor and sorting systems improve speed, accuracy, and productivity in manufacturing, packaging, and warehousing operations. Many suppliers offer customizable solutions to fit specific production requirements. Key exported products:

- Belt conveyors

- Roller conveyors

- Automated sorting lines

- Robotic pick-and-place units

CNC Machines

China exports CNC machines capable of milling, drilling, and shaping materials with high precision. These machines serve industries like metalworking, woodworking, automotive, and electronics, and are compliant with international quality standards. Chinese CNC machines are often customizable and technologically advanced while remaining competitively priced.

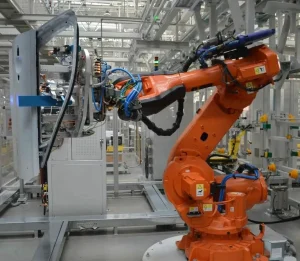

Industrial Robots

China is a major exporter of industrial robots, widely used in automotive, electronics, and general manufacturing. Features include:

- Robotic arms for welding, painting, assembly, palletizing, and material handling

- Advanced technologies such as AI, machine vision, and smart control systems

These robots enhance efficiency, reduce labor costs, and ensure consistent product quality in both large factories and smaller workshops.

PLCs (Programmable Logic Controllers)

PLCs are critical for automating production lines, controlling machinery, and managing complex industrial systems. China produces cost-effective, reliable PLCs compatible with a wide range of industrial applications and compliant with international standards, making it a trusted source for automation control equipment.

Packaging and Labeling Machines

Chinese packaging and labeling machines support industries like food, pharmaceuticals, cosmetics, and logistics. They improve operational efficiency and accuracy, and include:

- Filling equipment

- Sealing machines

- Wrapping equipment

- Labeling machines

- Coding equipment

Control Panels and HMIs

China exports a variety of control panels and HMIs (Human-Machine Interfaces) for monitoring and managing industrial automation systems. Key components include:

- Touchscreen panels

- Programmable displays

- Customized control units

Benefits of Importing Automation Equipment from China

Importing industrial automation systems from China offers several competitive advantages:

- Cost Advantage: Lower production and labor costs allow importers to achieve higher profit margins or offer more competitive pricing.

- Wide Product Range: From basic control panels to advanced robotic systems, China provides a one-stop sourcing solution for diverse industrial needs.

- High Quality: Many products meet international certifications (ISO, CE), making them suitable for demanding markets globally.

- Customization and Innovation: Suppliers often provide tailored solutions and invest in R&Dto stay technologically current.

- Scalability and Mass Production: High production capacity allows suppliers to fulfill bulk orders quickly, supporting business growth and urgent project needs.

How to Import Automation Equipment from China

Successfully importing automation systems and equipment requires a clear process:

- Find Reputable Suppliers

Look for suppliers with verified experience, certifications (ISO, CE), and positive reviews. Trusted platforms or trade consulting services help identify reliable partners. - Check Product Quality and Pricing

Request quotations, product samples, or factory audits to compare suppliers on cost, quality, and performance. - Negotiate Terms

Discuss payment methods (T/T, L/C), production timelines, packaging, and shipping terms (FOB, CIF). - Place Your Order

Once confident in quality and terms, issue a purchase order and pay the agreed deposit. - Arrange Shipping and Logistics

Select air or sea freight based on urgency and cost. Prepare all necessary customs documents (invoice, packing list, certificate of origin). - Clear Customs

Work with local customs brokers to handle import duties and clearance efficiently. - Receive, Install, and Test Equipment

Inspect the shipment upon arrival, install the systems, and ensure full operational functionality.

Why Using Specialized Logistics Support Can Boost ROI

Partnering with experienced logistics and sourcing specialists can save time, reduce costs, and simplify complex import procedures:

- Years of Experience: Expert handling of international trade ensures compliance with customs and shipping regulations.

- Cost-Effective Solutions: Optimize shipping and handling without compromising quality.

- End-to-End Services: From supplier coordination to last-mile delivery, every step is managed efficiently.

- Automation Equipment Expertise: Specialized experience ensures safe and appropriate transport of sensitive systems.

- Strong Supplier Networks in China: Efficiently manage sourcing, inspection, and shipment from trusted manufacturers.

- Time-Saving Process: Streamlined operations reduce administrative burdens and delays.

- Proven Track Record: Reliable support for importers in multiple regions, enhancing confidence and operational security.

Why Welleshaft Is Your Trusted Industrial Automation Sourcing Partner

Choosing Welleshaft as a sourcing partner goes beyond buying individual components—it ensures system-level reliability for your industrial automation needs. By providing verified automation parts, technical compatibility assessment, and transparent pricing, Welleshaft reduces procurement risk, supports fast global delivery, and guarantees authentic, certified components. Their ability to offer customization, flexible order sizes, and lifecycle support allows manufacturers, distributors, and repair centers to maintain continuous production, minimize downtime, and stay competitive in global markets. Working with a trusted partner like Welleshaft ensures your automation systems operate efficiently, safely, and consistently over the long term.

FAQ

What are the risks of using counterfeit or unverified automation parts?

Counterfeit components can fail prematurely, cause production downtime, violate safety regulations, and lead to costly maintenance or recalls.

How can predictive maintenance improve automation system performance?

By monitoring sensor and equipment data in real-time, predictive maintenance identifies potential failures before they occur, reducing unplanned downtime and extending component lifespan.

Why is lifecycle planning important for automation parts?

Planning for spare parts availability, obsolescence, and backward compatibility ensures continuous operation, minimizes forced upgrades, and protects production continuity.

Welleshaft Engineering Team, led by Mr. Xu, provides expert industrial automation solutions. From certified parts sourcing to system integration and lifecycle support, Welleshaft helps businesses optimize production, cut downtime, and ensure reliable, compliant operations worldwide.