High-Precision Parts Manufacturing: CNC, Casting, and Future Technologies

Why Does High Precision Matter in CNC and Casting Manufacturing?

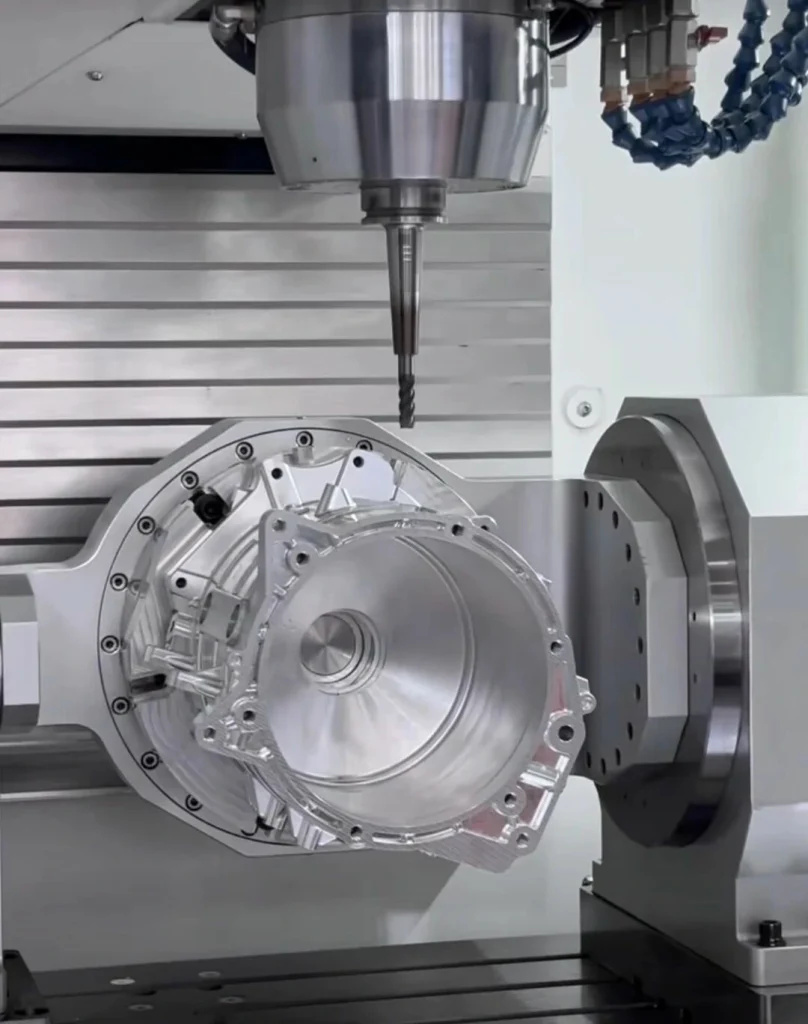

In CNC and precision machining, accuracy is everything. High-Precision CNC Machined Parts and Precision Casting ensure complex assemblies fit perfectly, reducing misalignment, operational failures, and rework. From automotive gears to surgical tools and miniature electronics, these components meet exacting tolerances that conventional methods can’t achieve. By combining advanced CNC processes, 3- and 5-axis machining, and meticulous quality control, manufacturers deliver reliable, durable parts while optimizing material use, supporting sustainability, and maintaining a competitive edge in industries where fractions of a millimeter matter.

The Difference Between Manufactured and Fabricated Parts

Manufactured and fabricated parts differ, and understanding this helps buyers make smarter sourcing decisions. High-Precision CNC Machined Parts and Precision Casting transform raw materials into consistent, interchangeable components, while fabrication cuts, bends, and assembles materials. OEM buyers prioritizing scalability and stable supply usually choose CNC-machined parts over simple fabrication.

Benefits of High Precision

High-precision manufacturing focuses on producing parts with extremely tight tolerances, often down to a few micrometers, and it plays a direct role in lowering production risk and total cost. When tolerance levels reach IT5, with accuracy from 10–0.1 μm and ultra-smooth surfaces, assembly becomes faster and cleaner. As a result, manufacturers reduce secondary grinding, cut rework, and streamline final fitting. This matters even more in CNC machining aluminum, stainless steel precision machining, and 17-4 PH stainless steel components, where tighter tolerances improve wear resistance and mating accuracy. In addition, intelligent machines minimize human error and support fast prototyping from one-off samples to full production. For buyers, this means shorter lead times, predictable quality, and long-term reliability that directly supports scalable procurement decisions.

Uses of High-Precision Components

High-precision components are used in hydraulic engines, medical devices, aerospace, and micro-mechanical systems where accuracy affects performance and safety. CNC turning parts like valve bodies and precision-machined metals support high-volume and custom production. Advanced medical equipment relies on miniature stainless steel, copper, carbon steel, and bronze parts, while gears, pinions, cams, and drives demand repeatable accuracy. Buyers increasingly choose vacuum casting and precision machining suppliers for material control, scalable output, and consistent quality.

How Did High-Precision Components Evolve with CNC and Casting Technologies?

Origins of High-Precision Components

High-precision components evolved from early industrial needs when lathes and sand casting couldn’t meet accuracy demands. The Industrial Revolution, new machine tools, and the micrometer enabled micron-level tolerances and complex parts. Improved alloys, stainless steel, and advanced casting, driven by aerospace demands, established today’s reliable, repeatable precision manufacturing for critical applications.

Evolution Over Time

Precision machining advanced with CNC and 5- or 7-axis machines for deep holes and complex shapes. Investment casting methods like shell molding and lost foam improved surface finish and repeatable dimensions. CAD/CAM systems and modern materials—stainless steel, composites, and specialty alloys—enable lighter, stronger, and durable parts, delivering faster, consistent, high-precision components for demanding industries.

Fundamental Concepts

High-Precision CNC Machined Parts and Precision Casting rely on tolerance control, material behavior, and metrology to meet exact specifications. Tools like CMMs, surface testers, and centerless grinders verify accuracy, while regular calibration and standardized processes ensure repeatable quality and reliable parts for critical applications.

Implementation Techniques

Manufacturers achieve high-precision components by combining techniques like CNC precision turning parts, Swiss lathe machining, Die casting, Vacuum casting, and precision casting, selecting the method based on geometry and production volume. To further enhance functionality and durability, they use secondary processes such as drilling, boring, centerless grinding, and surface treatment. Modern methods like laser cutting and additive manufacturing add flexibility, allowing intricate designs, clean edges, and rapid prototyping. By carefully choosing the right combination of techniques and maintaining strict quality control, manufacturers ensure each part meets exacting standards, giving buyers reliable, durable, and precisely engineered components for both high-volume and customized applications.

Which Materials and Casting Processes Enable Precision Manufacturing?

Stainless Steel, Alloy Steel, Titanium, Brass

In high-precision parts manufacturing, selecting the right material directly impacts durability, performance, and cost-efficiency. Common choices include stainless steel, alloy steel, titanium, and brass, each offering distinct advantages depending on the application.

- Stainless steel and 17-4 PH variants provide high strength and corrosion resistance, ideal for medical and aerospace uses.

- Alloy steeldelivers toughness and wear resistance for heavy-duty machinery

- titaniu moffers a lightweight, high-strength option perfect for aerospace components.

- Brass excels in machinability and intricate designs, often used in electronics and medical parts.

Casting methods—from green sand and shell molding to investment and vacuum casting—further balance accuracy, surface finish, and cost.

The table below highlights typical precision casting options:

| Process | Typical Materials | Accuracy | Applications |

| Investment Casting | Stainless steel, 17-4 PH | High | Aerospace, medical |

| Sand Casting | Ferrous, non-ferrous | Medium | Machinery components |

| Vacuum Casting | Resins, prototypes | Medium–High | OEM validation |

| Shell Molding | Alloy steel | High | Precision machinery |

By strategically combining materials and processes, manufacturers ensure each high-precision component meets exacting standards for performance and reliability.

Which Industries Rely on High-Precision CNC and Casting Parts?

Aerospace, Automotive, Medical, Electronics, Energy

High-precision parts manufacturing drives efficiency and reliability across multiple industries, from aerospace and automotive to medical devices and electronics.

- In aerospace, tight tolerances in engines, landing gear, and navigation systems reduce errors and boost safety. Components like turbine blades, brake pads, and engine parts demand a reliable CNC machining parts manufacturer, delivering precision and consistent quality for safety-critical applications.

- In automotive, precision components optimize engines, transmissions, and advanced technologies like EVs and autonomous vehicles. Precision manufacturing ensures these parts meet exact specifications, delivering reliability, durability, and peak performance under stress.

- In the medical field, precision parts for surgical tools, implants, and diagnostics ensure patient safety and reduce waste. Precision components deliver the accuracy needed for effective, reliable medical applications.

- electronics benefit from small, intricate parts that enable powerful, miniaturized devices.

Global OEMs increasingly turn to CNC machining parts suppliers who combine automated inspection and metrology to deliver consistent, compliant components. The table below highlights key industry applications:

| Industry | Applications | Benefits |

| Aerospace | Engines, landing gear, navigation systems | Safety, reliability |

| Automotive | Engines, transmissions, EV components | Efficiency, performance |

| Medical | Surgical tools, implants, diagnostics | Safety, precision, minimal waste |

| Electronics | Circuit boards, smartphones, microdevices | Miniaturization, performance, integration |

By integrating advanced machining, inspection, and CNC precision parts, manufacturers help businesses meet modern technology demands while reducing costs and improving product quality.

What Are the Benefits and Limitations of High-Precision Manufacturing?

Advantages in Production

High-precision manufacturing reduces costs and errors while improving material efficiency. Using CNC machining, manufacturers cut labor, boost yield, and scale production without losing tight tolerances. Surface treatments like zinc-nickel, chrome, or nickel plating enhance durability, while micro and complex parts drive innovation in medical, electronics, and high-tech industries, ensuring consistent, high-quality components.

Potential Limitations

High-Precision CNC Machined Parts and Precision Casting deliver superior quality but involve higher costs and technical challenges. Deep hole drilling, casting vs. forging, and heat management require careful planning, skilled operators, and proper material selection. Using advanced technologies and supplier collaboration ensures reliable, efficient, and innovative precision parts across industries.

How Are CNC, Metrology, and Automation Shaping Precision Manufacturing?

Current Technologies

Today’s precision machining relies on advanced CNC systems, Swiss machines, grinding, and centerless equipment to achieve repeatable results, while metrology verifies dimensions in real time. Combined with IoT for monitoring, robotics for delicate assembly, and AI for predictive quality control, manufacturers can optimize processes, reduce downtime, and enhance efficiency. As a result, precision machined parts suppliers deliver consistent, high-quality components across global markets, supporting industries that demand reliability, innovation, and scalable production without compromising accuracy.

Emerging Technologies and Trends

The future of high-precision components is driven by AI inspection, smart tooling, micro manufacturing, and automation. Advances in nanomaterials and smart materials enable lighter, stronger, and precise miniaturized parts. Machine learning optimizes production and predictive maintenance. Growing demand for micro and high-precision components in regulated industries, highlighted by events like Medtec China 2025, rewards companies adopting these innovations.

Why Choose Welleshaft for Precision CNC and Casting Solutions?

Welleshaft combines CNC precision machining services, precision casting, and advanced metrology to support global OEMs. With experience in high precision CNC machining parts, surface treatment, and custom precision manufacturing, Welleshaft helps clients reduce risk, improve quality, and accelerate time to market.

Frequently Asked Questions about High Precision Parts Manufacturing

What are high-precision parts?

High-precision parts made via CNC machining or precision casting meet micron-level tolerances, verified by metrology and surface treatments, ensuring consistent, reliable, and high-quality components for aerospace and medical applications.

How does precision machining work?

Precision machining uses CNC milling, turning, Swiss lathes, drilling, and boring to produce exact, high-precision parts with consistent dimensions and minimal errors, ensuring efficiency and reliability for critical industries.

Why choose precision manufacturing?

Precision manufacturing improves efficiency, lowers failure risks, and ensures long-term performance. Using CNC machining and automation, manufacturers streamline production, minimize waste, and deliver reliable, high-quality components for demanding industries.

What Materials and Processes Are Best for High-Precision Micro and Small Components?

For high-precision micro components, material and process matter. 17-4 PH stainless steel and aluminum offer strength and corrosion resistance, while Swiss lathe and micro CNC ensure tight tolerances and smooth finishes, delivering reliable parts for medical, aerospace, and electronics applications.

Provided by the Welleshaft Engineering Team, led by Mr. Xu, our experts use high-precision CNC machining and precision casting to help OEMs reduce risk, improve quality, and speed time to market, delivering reliable components for aerospace, automotive, medical, and electronics industries.