Cost-Efficient Casting Alloys Manufacturing: Reducing Waste and Optimizing Production

In modern manufacturing, Cost-Efficient Casting Alloys Manufacturing faces the challenge of balancing quality with cost-efficiency. High production costs, wasted materials, and low yield are common pain points in metal casting alloys production. Companies often struggle to maintain production efficiency while reducing scrap and ensuring consistent part quality. In this article, we explore strategies to optimize industrial casting alloys manufacturing, highlight process improvements, and provide actionable insights for achieving high-yield, low-cost alloy casting manufacturing.

Understanding the Challenges in Industrial Casting Alloys Manufacturing

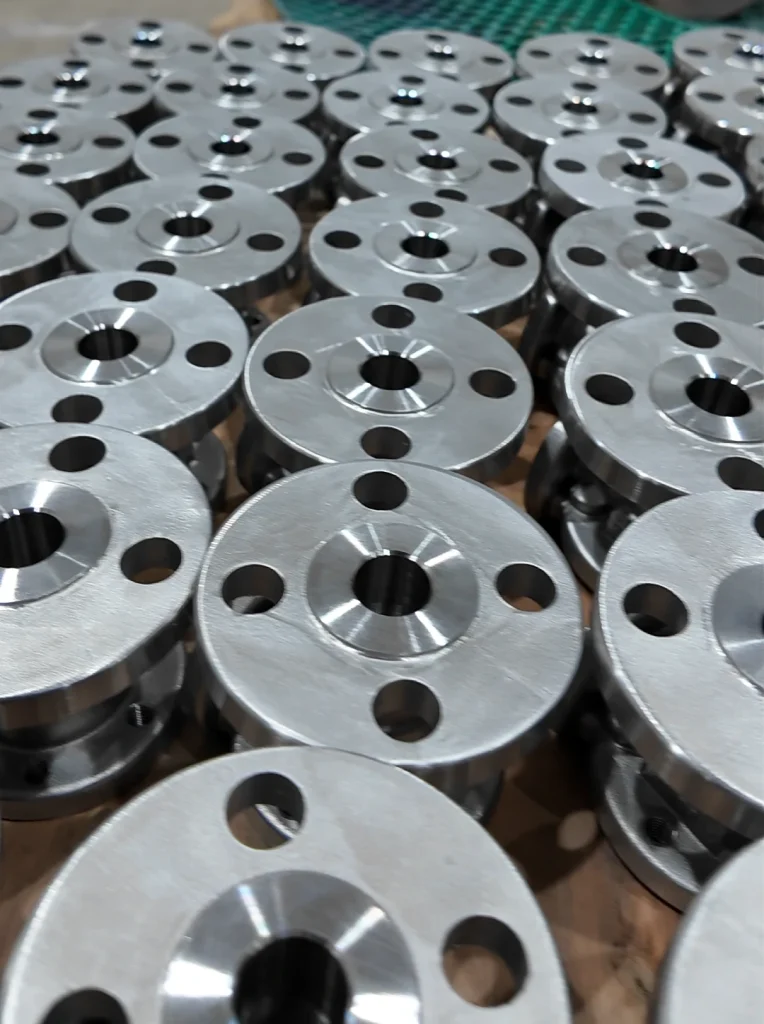

Industrial casting alloys manufacturing involves complex processes where molten metals are poured into molds to produce components for automotive, aerospace, and heavy machinery applications. Despite technological advances, common inefficiencies include:

- Material Waste– Overpouring, sprues, gates, and excess risers can generate substantial scrap.

- Low Yield– Misruns, shrinkage defects, or porosity lead to rejected parts and rework.

- High Energy Costs– Melting and maintaining precise temperatures consumes significant energy.

- Process Variability– Variations in mold design, alloy composition, or temperature control impact consistency and quality.

Addressing these challenges is crucial for achieving cost-efficient casting alloys manufacturing services while maintaining high standards in precision casting alloys manufacturing and automotive casting alloys manufacturing.

Efficient Alloy Casting Production Process Optimization

Optimizing the alloy casting manufacturing process can significantly improve yield and reduce material waste. Key strategies include:

Streamlining Custom Alloy Casting Manufacturing

- Designing molds and gating systems for minimal turbulence reduces defects and scrap.

- Using simulation software to model metal flow and solidification can predict problem areas and optimize riser placement.

- Standardizing processes for commonly used alloys improves consistency and reduces setup times.

Implementing High-Yield Low-Cost Alloy Casting Manufacturing Techniques

- Adopting controlled pouring techniques and temperature regulation minimizes porosity and cold shuts.

- Reclaiming non-ferrous alloy casting manufacturing waste materials efficiently reduces raw material costs.

- Implementing quality checkpoints during the production cycle ensures defects are caught early, preventing extensive rework.

Cost Reduction Strategies in Metal Casting Alloys Production

Reducing costs without compromising quality requires a combination of engineering, process control, and strategic supplier management. Practical methods include:

Budget-Friendly Alloy Casting Services for OEMs

- Partnering with certified cost-effective alloy casting suppliers ensures competitive pricing and reliable quality.

- Small-batch production for prototype or limited-run orders can avoid excessive inventory costs.

- On-demand affordable alloy casting solutions allow manufacturers to scale production according to real demand.

Industrial Alloy Casting Cost Reduction Strategies

- Lean manufacturing principles, such as minimizing movement, improving workflow, and eliminating unnecessary steps, can cut labor and overhead costs.

- Process automation in high-volume lines reduces human error and maintains consistent quality.

- Optimizing energy usage during melting and maintaining precise temperature control lowers utility expenses.

Precision Casting Alloys Manufacturing for Quality and Cost Efficiency

Precision casting alloys manufacturing is ideal for industries requiring intricate components, such as automotive and aerospace. Achieving cost-efficiency in this area involves:

- Advanced Simulation and Modeling– Predicting flow patterns and shrinkage zones minimizes trial-and-error production runs.

- High-Strength Alloy Casting Manufacturing Practices– Using high-strength alloys efficiently ensures durability while avoiding overuse of expensive materials.

- Quality-Controlled Low-Cost Alloy Casting Production– Implementing inline inspections and non-destructive testing maintains consistent product quality without excessive scrap.

Small-Batch and On-Demand Alloy Casting Solutions

Many OEMs and industrial clients require flexibility in production. Small-batch cost-efficient alloy casting manufacturing can be highly cost-effective when designed correctly:

- Modular tooling allows quick changeovers between different component designs.

- Efficient material planning reduces excess stock and minimizes waste.

- On-demand production aligns closely with supply chain needs, improving cash flow and reducing storage costs.

Maintaining Quality While Reducing Costs

While cost efficiency is essential, quality must not be compromised. Approaches include:

- Working with certified suppliers to ensure raw materials meet specifications.

- Implementing process controls, including precise temperature management and automated monitoring.

- Conducting rigorous inspections to prevent defective parts from reaching clients.

- Obtaining relevant certifications for manufacturing processes, reinforcing trust and compliance with industry standards.

Industries Benefiting from Cost-Efficient Alloy Casting Manufacturing

Cost-efficient alloy casting solutions have wide applications across industries:

- Automotive Casting Alloys Manufacturing– Engines, transmission components, and structural parts.

- Non-Ferrous Alloy Casting Manufacturing– Aluminum, copper, and zinc alloys for electrical and industrial applications.

- Industrial Machinery and Heavy Equipment– Large-scale castings for durable mechanical components.

- Precision Engineering– Aerospace, medical, and high-tech components requiring strict tolerances.

Optimizing Alloy Casting Processes to Save Money

Optimizing casting processes is an ongoing effort. Practical steps include:

- Data Collection– Measure scrap rates, energy consumption, and cycle times.

- Simulation & Redesign– Model molds, gating, and risers to reduce material waste.

- Process Standardization– Establish repeatable procedures for consistent quality.

- Continuous Improvement– Review production metrics regularly to identify new cost-saving opportunities.

Through these steps, manufacturers can achieve affordable alloy casting production solutions and sustainable cost-efficient casting alloys manufacturing services.

Welleshaft has 15+ years in industrial and precision alloy casting, leading projects in high-strength, custom, automotive, and non-ferrous castings. He specializes in process optimization, quality control, and cost-efficient production for global OEMs.