Aluminum Extrusion Services | Welleshaft

1.What Is Aluminum Extrusion?

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to produce continuous shapes with a uniform cross-section. At Welleshaft, we offer high-precision Aluminum Extrusion Services that ensure structural strength and aesthetic quality. Our process enhances performance, reduces weight, and improves corrosion resistance. From T-slot rails to frames and enclosures, we support fast prototyping and mass production with reliable precision.

Extrusion Terminology Includes:

- Extrusion Ratio: Die area vs. billet area

- Extrusion Pressure: Required force for material flow

- Extruded Aluminum Process: From billet to cooled profile

- Hydraulic Extrusion Press: Main machine driving the process

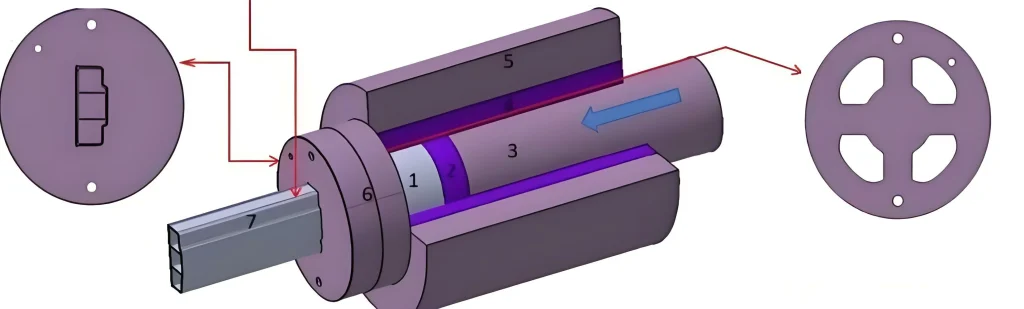

2.Aluminium Extrusion Process Explained

Our process starts with aluminum billet preheating, then hydraulic pressing through precision dies. This creates seamless aluminum profiles tailored to your application. Below is the simplified flow:

📊 [Process Diagram Placeholder]

Billet → Heated → Extruded (Press) → Cooled → Cut → Machined (Secondary)

We use fully automated aluminum extrusion press machines and advanced extruder pressure control to guarantee consistency and dimensional accuracy across batches.

(1)Types of Aluminum Extrusion Profiles & Alloys

Welleshaft offers both solid and hollow extruded aluminum profiles, including:

1.6061-T6 aluminum extrusion

2.7075 aluminum extrusion

3.Aluminum extrusion bar and frame

4.Heat sink extrusion aluminum profiles

①Alloy Comparison Table

| Alloy | Strength | Common Applications |

| 6061-T6 | Good corrosion resistance | Architecture, general purpose |

| 7075-T6 | High tensile strength | Aerospace, defense, tooling |

3.Aluminium Extrusion Machining & Secondary Operations

We go beyond raw extrusion—we offer machined aluminum extrusion solutions for complex parts:

1.CNC machining

2.Drilling and tapping

3.Precision cutting

4.Bending and deburring

We support tight-tolerance projects and customized profiles for industries like automotive, solar, and industrial automation.

(1)How Do I Cut, Drill, or Bend Aluminum Extrusion?

Recommended: carbide-tipped saws, proper coolant, and customized dies for safe bending. Welleshaft offers full machining services for precise fabrication.

4.Common Aluminum Extrusion Questions

(1)What is the difference between 6061 and 7075 aluminum extrusion?

6061 is more weldable and machinable, ideal for general structures. 7075 offers higher strength but is harder to machine.

(3)How does an aluminum extrusion press work?

The hydraulic press pushes heated billets through a steel die using several thousand tons of force, shaping the material without defects.

5.Aluminum Extrusion vs Other Metal Forming Processes

| Parameter | Aluminum Extrusion | Die Casting | Metal Rolling |

| Tooling Cost | Medium | High | Low |

| Design Flexibility | High | Medium | Low |

| Volume Suitability | Low–High | High | Very High |

| Strength-to-Weight | High | Medium | High |

Welleshaft recommends extrusion for lightweight structural components where custom cross-sections are needed.

6.Welleshaft Capabilities & Equipment

Welleshaft operates multiple extrusion lines with press capacities ranging from 600 to 2,500 tons. We maintain:

1.ISO 9001:2015-certified facilities

2.Precision extrusion dies (customizable)

3.Online thickness, width, and surface quality monitors

4.CNC machines for post-processing

Our production lines ensure short lead times, consistent tolerances, and high material yield.

7.Our Technical Team & Certifications

With over 12 years of industry experience, the Welleshaft engineering team includes:

1.Certified Mechanical Engineers

2.SolidWorks & AutoCAD designers

3.On-site QA inspectors (AQL & CMM-based)

4.PMP-certified project managers

We ensure regulatory and market compliance for industries requiring REACH, RoHS, MIL-STD, or EN standards.

8.Customer Case Study: Industrial Automation Supplier

Client: Germany-based factory automation integrator

Challenge: Required lightweight yet rigid enclosures for robotic arms

Solution: Custom-designed T-slot extrusion with tight tolerance and CNC-milled joints

Result: 22% weight reduction, 30% faster assembly, zero rework rate

“Welleshaft delivered consistent, high-precision extrusions even in tight delivery windows.” – Client QA Manager

9.Application Scenarios: Where Is Aluminum Extrusion Used?

🚗 Automotive: Roof rails, seat frames, bumper reinforcement

🏢 Construction: Window frames, curtain wall systems

⚙️ Machinery: Framing systems, guards, conveyors

☀️ Energy: Solar panel mounting, heat sinks

🚚 Transport: Trailers, railway components, cargo framing

10.Why Choose Welleshaft?

✅ Consistent quality: Dimensional accuracy & surface finish

✅ Fast prototyping: In-house die-making & rapid delivery

✅ Transparent pricing: Quotation by kg or ft

✅ Sustainability: Aluminum extrusion scrap price optimization & material reuse

We eliminate common pain points such as variable tolerances, long tooling delays, and non-standard profiles.

This article is produced by the Welleshaft Technical Content Team, composed of certified engineers and quality experts. With a global presence, Welleshaft delivers custom aluminum extrusion profiles, hydraulic extrusion press expertise, and machined aluminum extrusion services to clients across industrial, energy, and structural sectors.