Complete Guide to Servo Motors: How They Work, Applications, and Precision CNC Housing Machining

What is a Servo Motor?

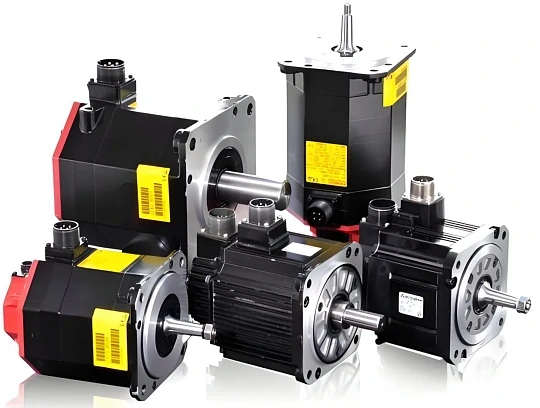

A servo motor operates through the principles of electromagnetism, where a generated energy field powers the rotor. Over time, continuous advancements have transformed these devices from auxiliary drives into reliable main drives for a wide range of industrial applications. Today, a modern servo motor features a compact, space-saving design, offers flexible adaptability, and enables highly dynamic and precise operations. As a result, businesses can achieve more efficient, accurate, and scalable automation processes by integrating these motors into their systems.

What Are the Key Advantages of Servo Motors in Industrial Automation?

Enhanced Precision and Accuracy

The combination of feedback mechanisms, closed-loop control, and advanced error correction enables servo motors to deliver unmatched precision in robotics and industrial automation. By providing exact control over angular and rotational positions, servo motors ensure highly accurate movements, allowing delicate tasks and object manipulation with exceptional accuracy. This level of precision is essential for businesses seeking to enhance productivity, reduce errors, and achieve consistent results in automated operations.

Real-Time Feedback for Superior Control

Servo motors operate using signals such as Pulse Width Modulation (PWM), which directs the movement of the motor shaft. The signal’s duration determines the rotational direction, while integrated sensors—like potentiometers in closed-loop DC servo motors—continuously monitor motion, enabling the motor to stop or adjust direction as needed. Additionally, encoders or resolvers provide high-resolution feedback, detecting even minimal changes in position. This real-time monitoring ensures precise, reliable control, helping industrial systems maintain consistent performance under demanding conditions.

Consistent Torque and High-Speed Performance

In applications such as CNC machines, maintaining consistent torque at varying speeds is critical. Servo motors excel in tasks that require fine positioning accuracy and high resolution. Their speed often surpasses that of stepper motors, reaching several thousand RPM, while providing stable torque across a wide range of operating conditions. This combination of speed and power allows automated equipment to run efficiently, boosting productivity and reducing operational delays.

Dynamic Response for Agile Operations

The superior dynamic response of servo motors allows them to react instantly to commands, adjusting speed and direction seamlessly. This agility is crucial for applications that demand quick adaptation, including robotics, precision machining, and automated assembly. By combining rapid responsiveness with precision control, servo motors enable businesses to implement highly efficient, flexible, and reliable automation solutions.

Where Are Servo Motors Used?

Servo Motors in Robotics Applications

In robotics, servo motors are essential for performing tasks that are repetitive, demanding, and require high precision. Their ability to deliver accurate and agile movements makes them the backbone of modern robotic systems, enabling machines to operate reliably in complex environments.

Robotic Welding:

Servo motors provide precise motion control and rapid response for robotic welding arms, ensuring consistent weld quality and improved production efficiency.

Robotic Vehicles:

Autonomous vehicles, such as bomb disposal or inspection robots, rely on servo motors to control steering and navigation systems with accuracy and safety.

Key Benefits of Using Servo Motors in Robotics:

- Space-Efficient Design:Compact size allows seamless integration into robotic arms, wheels, or bodies.

- Exceptional Precision in Movement:Offers highly accurate control over both linear and angular positions, critical for delicate tasks.

- Flexible Scalability:Easily expandable by connecting multiple devices in a single power chain, supporting future growth.

- Continuous Software Enhancements:Regular software updates improve performance, responsiveness, and functionality over time.

Servo Motors in CNC Applications

Servo motors play a pivotal role in CNC machining, where precise control, dynamic response, and feedback are essential. By enabling highly accurate and repeatable operations, servo motors allow manufacturers to produce intricate designs, complex geometries, and fine surface finishes efficiently.

Machining Complex Geometries:

Equipped with servo motors, CNC machines can create detailed components across multiple industries, achieving tight tolerances and high-quality surfaces.

Positioning Axes:

Servo motors drive the movement of CNC machine axes, ensuring accurate and repeatable positioning of tools and workpieces.

Contouring and Engraving:

With servo motors, CNC machines can follow precise paths for contouring, engraving, and other intricate designs, expanding manufacturing capabilities.

Key Benefits of Using Servo Motors in CNC Machining:

- Simultaneous Control of Multiple Axes:Enables synchronized operations, improving efficiency and accuracy for complex tasks.

- Enhanced Monitoring with Feedback:Feedback mechanisms detect deviations, ensuring strict adherence to programmed commands.

- Consistent Processing Abilities:Maintains uniform execution in turning, cutting, trimming, and other operations, ensuring reliable results.

- Improved Accuracy and Reduced Maintenance:Eliminates mechanical components such as back shafts and pulleys, lowering maintenance costs while enhancing precision.

How Do Servo Motors Work?

A feedback device in a servo motor continuously monitors the motor’s behavior, allowing the controller to adjust inputs in real time for precise operation. The more sensitive this device is to subtle movements, the higher the accuracy and responsiveness of the servo motor, making it ideal for applications that demand exact positioning and reliable performance.

Motion in a servo motor begins when current flows through the electromagnet’s winding, creating a magnetic field. By reversing the current direction, the polarity of the field changes, controlling the interaction between the electromagnet and the permanent magnets. However, a single wire alone cannot generate sufficient force to move the rotor.

To amplify the magnetic effect, the wire is coiled multiple times, multiplying the magnetic field with each turn. Placing an iron core at the center of the winding further concentrates the magnetic field, creating a strong interaction with the permanent magnet. The resulting attraction or repulsion between the electromagnet and permanent magnet generates the torque needed for precise motion control.

As the electromagnet creates a moving attraction point on the stator, the rotor aligns itself with this point, producing rotation. By continuously adjusting the location of the magnetic attraction, the rotor rotates in sync with the stator, which is why these are often referred to as synchronous motors. This precise synchronization ensures that servo motors can deliver reliable, repeatable, and highly controlled motion, making them indispensable in industrial automation, robotics, and CNC machining applications.

Structure and Functioning of Servo Motors

A servo motor operates as a critical part of a closed-loop control system, also known as a feedback control system, where the actual output is continuously monitored and compared to the desired output. By adjusting the input signals based on real-time feedback, the system ensures precise motion, minimizes errors, and maintains highly accurate performance—making servo motors ideal for industrial automation, robotics, and CNC machining applications.

The mechanism of a servo motor integrates multiple essential components that work together seamlessly. These include the housing, stator, rotor, motor winding, drive gears, shaft, encoder, position potentiometer, and an optional cooling system. The electronic assembly, which acts as the “brain” of the device, incorporates the motor, controller board, and feedback elements to regulate speed, position, and torque. Drive gears reduce high-speed rotation to deliver controlled power, while the output spline transmits motion to connected machinery or robotic parts.

A key element is the servo controller, which serves as an intermediary between the motor and digital control systems, such as PLCs, converting signals to ensure smooth operation. Together, these components form a complete servo drive system, providing precise, reliable, and scalable motion control that empowers businesses to enhance efficiency, reduce errors, and expand automation capabilities.

Motor Shaft and Windings

The shaft and motor winding form the structural heart of a servo motor, functioning as the rotor and stator. From an external perspective, the stator—containing the motor winding—sits within the housing, which is made of highly conductive materials and can be designed in various ways. The thickness and diameter of the winding wire directly influence the magnetic field intensity and overall motor performance. Thinner wires allow for tighter, more numerous windings, which significantly affect the motor’s specifications.

Tightly wound stators provide several benefits and trade-offs:

- Amplified magnetic fieldfor stronger performance

- Increased maximum torque, ideal for heavy-load applications

- Higher countervoltageat elevated speeds

- Slightly reduced efficiencyand increased heat generation, which necessitates effective cooling solutions

This configuration enables servo motors to deliver extremely high power at low speeds, making them perfect for applications like extruders, shredders, and other machinery that require substantial torque without high rotational speed. At higher speeds, power output naturally decreases, but this reduction is negligible for such heavy-duty tasks. The exact design of the motor winding is always tailored to the specific operational requirements.

Inside the stator, the rotor—the servo motor shaft—reacts to the electromagnetic field generated by the winding as soon as external energy is applied. The shaft then transmits controlled motion to the connected machinery, enabling precise, reliable, and efficient operation across a wide range of industrial automation applications.

Cooling Systems (Air vs Water Cooling)

Cooling is a critical component of any servo motor, directly affecting performance, reliability, and operational efficiency. Depending on the application, servo motors can be cooled using air, oil, or water. Water cooling, in particular, allows the motor to deliver the highest nominal power within a compact design, significantly increasing power density. This higher power density not only maximizes performance but also offers an important economic advantage by reducing space requirements and preserving design flexibility in industrial machinery.

For applications with highly dynamic demands, liquid cooling—whether with water or hydraulic oil—offers several operational benefits. Compared to air cooling, it saves space by eliminating fans and minimizes maintenance, reducing servicing costs and machine downtime. In compact group installations where multiple servo motors operate in close proximity, liquid cooling prevents overheating, ensuring consistent performance and longer motor lifespan.

Equally important is the interaction between the servo motor and its servo controller. The controller acts as the communication bridge between the control unit, such as a PLC, and the motor itself. It converts and transmits signals accurately, enabling precise control over torque, speed, and position. This exact regulation allows motors to achieve and maintain target performance, providing highly dynamic, responsive movement that is essential for robotics, CNC machining, and other high-precision industrial applications.

Understanding Synchronous Servo Motors

A servo motor transforms electrical energy into controlled rotational motion, making it an essential component in robotics, CNC machining, and industrial automation. At its core, a servo motor consists of a stator, a permanent magnet rotor, and a feedback device, all working together to ensure precise, repeatable performance.

The stator serves as the electromagnetic foundation of the motor. When current passes through its copper windings, it generates a magnetic field that interacts with the rotor, producing motion. The rotor, which contains an output shaft embedded within a steel-laminated iron mass, is connected to the load or machinery that needs to be controlled. Bearings support the rotor, keeping the shaft perfectly aligned within the stator, while the embedded permanent magnets create a consistent magnetic field that drives smooth and accurate rotation.

This design allows servo motors to deliver high torque, precise positioning, and dynamic responsiveness, making them ideal for applications where efficiency, reliability, and accuracy directly impact operational performance and productivity.

What is an AC Servo Motor?

An AC servo motor is a specialized type of servo motor that uses alternating current (AC) to deliver precise motion control. Known for their high efficiency and reliable performance, these motors excel in applications requiring accurate positioning, speed regulation, and torque control.

The working principle of an AC servo motor involves converting AC electrical energy into mechanical motion through the interaction of a rotating magnetic field and a stationary stator. The stator, containing the motor windings, generates the magnetic field, while the rotor, connected to the output shaft, rotates in response. Integrated feedback mechanisms continuously monitor performance, enabling real-time adjustments for precise control.

How AC Servo Motors Differ from Standard AC Motors

Unlike conventional AC motors, which are designed for continuous operation at a constant speed, AC servo motors are optimized for dynamic performance. They respond rapidly to control signals, making them ideal for tasks that demand high precision and quick adjustments. Key distinctions include:

- Feedback Mechanism:AC servo motors incorporate encoders or resolvers that monitor and adjust the motor’s performance in real time, ensuring accurate positioning and motion control.

- Advanced Control System:Sophisticated servo drives manage power supply and modulate the motor’s operation, allowing precise regulation of speed and torque.

- Enhanced Construction:Built with high-quality materials and tighter tolerances, AC servo motors provide superior reliability and durability in demanding industrial applications.

- Torque and Speed Characteristics:Designed to deliver high torque at low speeds, AC servo motors maintain consistent performance across a wide range of speeds, whereas standard AC motors typically achieve optimal efficiency at a single speed.

By combining precision, rapid responsiveness, and consistent torque, AC servo motors offer a significant advantage in industrial automation, robotics, CNC machining, and other applications where accuracy and reliability directly impact productivity and operational efficiency.

The Evolution and Operation of AC Servo Motors

AC servo motors have undergone remarkable advancements since their inception, evolving from simple positioning devices to highly sophisticated motion control solutions. Early versions were limited to basic tasks in industrial applications and lacked the precision, efficiency, and responsiveness of modern AC servo motors. The introduction of feedback systems, such as encoders and resolvers, accelerated technological progress, enabling significantly higher accuracy and control.

By the mid-20th century, the integration of digital control systems and microprocessors revolutionized AC servo motor performance. Closed-loop control systems became standard, continuously monitoring output and making real-time adjustments to maintain desired performance levels. Later, brushless AC servo motors emerged, offering higher efficiency, reduced maintenance, and more compact designs through the use of permanent magnets and advanced electronic controls.

In recent years, the combination of high-performance materials, innovative manufacturing techniques, and sophisticated algorithms has pushed the limits of AC servo motors even further. Modern motors deliver higher torque density, faster response times, and improved energy efficiency, making them indispensable in applications that demand precise motion control, from industrial automation to robotics and CNC machining.

How AC Servo Motors Work

An AC servo motor converts electrical energy into mechanical motion using the interaction of the stator and rotor. The stator, equipped with windings, generates a rotating magnetic field when supplied with alternating current (AC). This magnetic field interacts with the rotor, which contains permanent magnets or conductive windings, causing it to rotate with precision.

The operation of an AC servo motor can be understood in five key steps:

- Power Input:The motor receives AC power, regulated by a servo drive that controls voltage and current to optimize performance.

- Magnetic Field Generation:Energized stator windings produce a rotating magnetic field, with the frequency and phase of the AC supply determining speed and direction.

- Rotor Interaction:The magnetic field induces motion in the rotor, whose design ensures efficient torque generation and smooth rotation.

- Feedback System:Integrated feedback devices, such as encoders or resolvers, constantly monitor rotor position, speed, and torque.

- Control Adjustments:The feedback data is sent to the servo drive, which fine-tunes input parameters in real time, ensuring precise positioning, accurate speed regulation, and consistent torque.

Through this combination of advanced design, feedback control, and dynamic operation, AC servo motors provide reliable, high-performance motion control, enhancing productivity and precision across a wide range of industrial and automated systems.

Construction and Components

An AC servo motor relies on the seamless interaction of multiple components to deliver precise motion control, high efficiency, and reliable performance across industrial and automation applications. Understanding these components helps highlight why AC servo motors are essential in robotics, CNC machining, and other precision-driven machinery.

Stator

The stator is the stationary part of the motor that houses the windings, typically made of copper for excellent electrical conductivity. When AC power passes through these windings, it generates a rotating magnetic field that drives the rotor. The arrangement, thickness, and pattern of the windings directly affect the motor’s efficiency, torque, and overall performance. High-quality stators minimize energy losses and maximize magnetic flux, enabling smoother and more precise operations.

Rotor

The rotor is the rotating component that interacts with the stator’s magnetic field. It may include permanent magnets or conductive windings, depending on whether the motor is synchronous or asynchronous. As the magnetic field induces rotation, the rotor transfers mechanical motion to the connected machinery via the output shaft. Optimized rotor designs enhance torque, speed, and dynamic response, making them ideal for precision tasks.

Feedback Device (Encoder or Resolver)

A reliable feedback mechanism is critical for maintaining accuracy. Encoders convert the mechanical position of the rotor into electronic signals for precise control, with incremental encoders offering relative position data and absolute encoders providing exact shaft positions. Resolvers, on the other hand, are robust analog devices that deliver continuous position feedback, ensuring dependable performance in harsh industrial environments. These feedback devices enable real-time adjustments, reducing errors and improving overall system responsiveness.

Servo Drive

The servo drive, or servo amplifier, manages power delivery to the motor and interprets signals from the feedback device. By continuously adjusting voltage and current, it ensures the motor operates within specified parameters. Modern digital servo drives allow programmable control, communication interfaces, and advanced diagnostics, providing flexibility for complex motion tasks while maintaining precise speed, torque, and positioning control.

Control System

The control system integrates the servo drive with feedback mechanisms to regulate the AC servo motor’s performance. Using closed-loop control, the system continuously monitors rotor position, speed, and torque, making real-time adjustments that maximize accuracy, reduce overshoot, and maintain consistent operation under varying loads. This integration enhances productivity and ensures reliable operation in automated systems.

Bearings

Bearings support the rotor and shaft, reducing friction and wear while maintaining alignment. Common types include ball bearings for high-speed applications, roller bearings for heavy loads, and magnetic bearings in advanced designs. Proper lubrication and maintenance of bearings ensure smooth motion, long lifespan, and consistent performance.

Housing (Frame)

The housing encases all internal components, providing protection against dust, moisture, and mechanical impact. Often constructed from aluminum or cast iron, the housing supports the stator, rotor, and bearings while also dissipating heat through cooling fins or integrated channels. A well-designed housing ensures durability, structural stability, and reliable thermal management.

Cooling System (Optional)

Some applications require enhanced thermal management. AC servo motors may use air cooling, liquid cooling, or heat sinks to maintain optimal operating temperatures. Effective cooling prevents thermal overload, reduces maintenance needs, and allows motors to operate at higher power densities without compromising efficiency.

Shaft

The shaft transmits mechanical power from the rotor to the connected load, such as a conveyor, robotic arm, or CNC tool. Made from high-strength steel or stainless steel, the shaft is designed to handle torque, speed, and mechanical stress while being supported by bearings to ensure smooth rotation and longevity. Proper shaft design and maintenance directly influence the reliability and precision of the entire system.

Types of AC Servo Motors

When selecting the right AC servo motor, understanding the different types available is essential. Each type is engineered to meet specific performance demands, from ultra-precise positioning to continuous high-speed rotation. By matching the motor type to your application, you can significantly improve efficiency, accuracy, and long-term reliability.

Let’s explore the main types of AC servo motors and where they deliver the most value.

Synchronous AC Servo Motor

A synchronous AC servo motor operates at a constant speed synchronized with the frequency of the power supply. Because the rotor uses permanent magnets or a wound field, it locks in step with the stator’s rotating magnetic field. As a result, it delivers exceptionally smooth and precise motion.

Best suited for:

- Robotics and articulated robotic arms

- CNC machining centers

- Textile and packaging machinery

- Semiconductor equipment

Key advantages:

- High precision motion control

- Stable speed under variable loads

- Superior energy efficiency

- Excellent dynamic response

For industries that demand accuracy down to microns, a synchronous servo motor becomes the preferred choice.

Asynchronous (Induction) AC Servo Motor

Unlike synchronous motors, an asynchronous AC servo motor (also known as an induction servo motor) relies on electromagnetic induction. The rotor does not rotate in perfect sync with the stator field. Instead, controlled slip generates torque.

Because of its rugged construction, this motor type offers outstanding durability and cost efficiency.

Common applications:

- HVAC systems

- Conveyor systems

- Pumps and fans

- Material handling equipment

Key advantages:

- Cost-effective servo solution

- Durable and resistant to harsh environments

- Lower maintenance requirements

- Reliable variable speed control

For heavy-duty or budget-sensitive industrial systems, induction-based AC servo motors provide a practical balance between performance and cost.

Single-Phase AC Servo Motor

A single-phase AC servo motor operates using a single-phase AC power supply. Thanks to its simple construction and easy installation, it is commonly used in small-scale or light-duty applications.

Typical uses:

- Home appliances

- Small pumps

- Ventilation systems

- Compact automation devices

Key advantages:

- Affordable and simple design

- Easy integration

- Suitable for light-load motion tasks

Although not ideal for high-precision industrial robotics, single-phase systems offer dependable motion control for compact equipment.

Two-Phase AC Servo Motor

A two-phase AC servo motor improves control accuracy by using two stator windings positioned 90 degrees apart. This configuration generates a more refined rotating magnetic field, resulting in better speed and positional control.

Ideal applications:

- Industrial automation

- Precision robotics

- Medical imaging systems

- Laboratory equipment

Key advantages:

- Improved motion accuracy

- Higher efficiency than single-phase designs

- Enhanced responsiveness

For industries where precision directly affects output quality, two-phase designs offer measurable performance gains.

Positional Rotation AC Servo Motor

A positional rotation AC servo motor focuses on accurate angular positioning. It rotates to a specific angle based on control signals and continuously adjusts through feedback systems like encoders.

Common applications:

- Robotic joints

- CNC cutting tools

- Camera stabilization systems

- Automated inspection equipment

Key advantages:

- Extremely accurate angle control

- Fast response time

- Consistent repeatability

Whenever precise rotational positioning is required, this servo type ensures reliable closed-loop accuracy.

Continuous Rotation AC Servo Motor

A continuous rotation AC servo motor is engineered for uninterrupted 360-degree motion. Instead of stopping at a fixed angle, it regulates speed and direction dynamically.

Typical applications:

- Conveyor belts

- Electric vehicle drive systems

- Drone propulsion

- Industrial transport systems

Key advantages:

- High efficiency in continuous motion tasks

- Long operational lifespan

- Stable torque delivery

For systems that depend on constant movement, continuous rotation designs maximize productivity and uptime.

Linear Servo Motor

A linear servo motor converts electrical energy directly into linear motion, eliminating the need for mechanical conversion from rotary to linear movement. This direct-drive approach reduces mechanical wear and improves positioning precision.

Common uses:

- High-precision manufacturing equipment

- Semiconductor processing

- Medical surgical systems

- Automated assembly lines

Key advantages:

- Ultra-precise linear positioning

- Smooth, backlash-free motion

- Higher acceleration capability

- Reduced mechanical complexity

For advanced automation systems requiring micron-level accuracy, linear servo motors deliver unmatched performance.

Why Selecting the Right AC Servo Motor Matters

Choosing the appropriate AC servo motor type directly impacts system efficiency, motion accuracy, and operational lifespan. While synchronous motors excel in precision-driven industries, induction designs provide rugged reliability. Meanwhile, linear servo systems redefine high-speed, high-accuracy automation.

As industrial automation, robotics, CNC machining, and smart manufacturing continue to evolve, investing in the correct servo motor technology ensures greater productivity, lower maintenance costs, and superior motion control performance.

Important Metrics and Performance Factors

To achieve optimal performance and precision, understanding the essential metrics of AC servo motors—such as torque, speed, and voltage—is critical. These parameters not only guide the selection of the right motor for specific applications but also help maintain long-term reliability, efficiency, and cost-effectiveness.

Torque: Driving Force for Reliable Motion

Torque is the rotational force produced by the motor shaft, determining its ability to perform work under various load conditions. Measured in Newton-meters (Nm) or pound-feet (lb-ft), it is typically assessed with torque sensors or dynamometers during operation.

Key Torque Types

Continuous Torque – Represents the maximum torque a motor can deliver continuously without overheating. Essential for applications such as automated conveyor systems and manufacturing lines, where consistent load handling is required.

Peak Torque – Refers to short-duration torque bursts, usually during start-up or sudden load changes. This is critical for high-demand applications like CNC machines and robotic arms.

Torque-Speed Characteristics

Understanding the torque-speed relationship is vital. Typically, torque decreases as speed increases, illustrated by a torque-speed curve. This visualization helps engineers choose the right motor for dynamic operations, ensuring efficiency and reliability across all speed ranges.

Speed: Ensuring Precision in Motion

Speed, measured in revolutions per minute (RPM), defines how fast a motor can rotate. Accurate speed control is essential in robotics, CNC machining, and automated systems.

Rated Speed – The maximum speed a motor can sustain while delivering rated torque continuously. Maintaining rated speed is crucial for consistent operation in applications like production lines.

Maximum Speed – The top speed a motor can achieve for short periods. Useful for tasks requiring rapid positioning or temporary high-speed operations.

Advanced Speed Control Methods

Modern AC servo motors leverage several control strategies to achieve precise motion:

Vector Control (FOC) – Controls torque and speed by adjusting the motor’s magnetic field; ideal for robotics and CNC systems.

Closed-Loop Control – Uses real-time feedback to maintain exact speed and position, critical for medical devices and high-precision manufacturing.

Open-Loop Control – Operates based on preset commands; simpler but less precise, suitable for basic conveyor applications.

PWM (Pulse Width Modulation) – Efficiently regulates speed in fans, pumps, and variable-speed devices.

PID Control – Maintains stable and precise speed by correcting deviations from setpoints.

Direct Torque Control (DTC) – Provides rapid torque response and high efficiency for industrial drives and electric vehicles.

Voltage & Frequency Control – Adjusts speed via voltage or frequency; common in HVAC and basic automation setups.

Selecting the right control method can significantly enhance motor performance, reduce energy waste, and extend operational lifespan.

Voltage and Current: Powering Performance Safely

Voltage (V) drives current through the motor, while current (A) represents the flow of electrical charge. Both metrics are critical for determining power requirements and safe operational limits.

Rated Voltage – Maximum continuous voltage a motor can handle without performance degradation.

Rated Current – Maximum continuous current under normal operation to prevent overheating.

Proper management of voltage and current ensures efficient operation, prevents damage, and reduces maintenance costs.

Efficiency: Reducing Energy Loss and Costs

Efficiency measures how effectively electrical power converts to mechanical output. Most modern AC servo motors operate at 85–95% efficiency. Higher efficiency translates to:

Lower energy consumption

Reduced operational costs

Less heat generation

Longer motor lifespan

In industries where uptime and energy savings are critical, efficiency directly impacts ROI.

Inertia: Balancing Responsiveness and Stability

Inertia reflects a motor’s resistance to changes in motion, influenced by rotor mass and load distribution.

Rotor Inertia – Lower rotor inertia enables faster acceleration and deceleration, enhancing dynamic performance.

Load Inertia Matching – Properly matched motor and load inertia improves stability, reduces wear, and ensures smooth motion control.

Correct inertia management is essential for high-speed automation and precision robotics.

Feedback Resolution: The Backbone of Accuracy

High-resolution feedback devices, such as encoders and resolvers, are essential for precise position and speed control. Measured in counts per revolution (CPR) or degrees, higher resolution ensures:

Accurate motion

Smooth acceleration and deceleration

Reduced operational errors

Common Feedback Technologies

Optical Encoders – High-resolution, suitable for CNC and robotics.

Magnetic Encoders – Robust, reliable in harsh conditions.

Resolvers – Absolute position feedback, durable under extreme environments.

Hall Effect Sensors – Provide reliable position tracking in brushless motors.

Incremental & Absolute Encoders – Offer relative or unique position information, essential for precise automation.

Accurate feedback improves servo motor performance, minimizes downtime, and optimizes production efficiency.

Thermal Performance: Managing Heat for Longevity

Efficient thermal management ensures reliable motor operation and longevity.

Thermal Resistance – Measures the motor’s ability to dissipate heat; lower values improve heat management.

Operating Temperature Range – Defines safe ambient limits, typically -20°C to 80°C, preventing overheating and component damage.

Proper thermal design reduces failure risks and supports high-duty industrial operations.

Duty Cycle, Control Response, and Noise/Vibration

Duty Cycle – Indicates operating time versus rest time. For instance, a 50% duty cycle allows equal operation and rest, preventing thermal stress.

Control Response – Fast response times and high bandwidth ensure precise adjustments, critical for robotics and automation.

Noise & Vibration – Low noise (dB) and minimal vibration (m/s²) preserve equipment lifespan and maintain process accuracy, especially in CNC and medical applications.

What Affects Servo Motor Performance and Reliability? Key Factors and Best Practices

Best Practices for Servo Motor Reliability

Once you grasp how a servo motor operates and the crucial role its drive system plays in energy saving, the next step is ensuring your motor performs reliably under real-world conditions. Implementing the following best practices can maximize performance, extend lifespan, and protect your investment.

Invest in Tested Motors for Long-Term Reliability

Before purchasing, always verify how a motor has been tested and under what conditions it’s designed to operate. Leading motor manufacturers conduct rigorous tests for:

Vibration resistance

Electrical interference tolerance

Leakage prevention in submerged environments

Mist and moisture penetration

Extreme temperature endurance

Wear over time

High-standard OEMs discard designs that cannot withstand the equivalent of decades of use. For applications in processing or harsh industrial environments, rigorous testing is not optional—it’s essential. Choosing tested motors ensures they can survive tough cleaning procedures and demanding operational conditions.

Ensure Complete Waterproofing Beyond the Motor

Even if a motor is rated as waterproof, poor connections can become points of failure. Standards like IEC 60529 define Ingress Protection (IP) against solids and liquids:

The first digit (1–6) measures protection against solids

The second digit (1–8) measures protection against liquids

For instance, an IP67-rated motor is dust-tight and can handle full immersion up to one meter for 30 minutes. To maximize reliability, ensure both your motors and all related connections meet IP67 standards or higher.

Optimize Motor Placement for Performance

Motor location significantly impacts performance and longevity. Avoid placing motors in areas prone to constant exposure to liquids. Even if your motor is waterproof, keeping it dry whenever possible is the simplest way to prevent failures. Proper placement reduces maintenance needs and improves overall system reliability.

Maintain Coolant Carefully

While coolant is necessary for many systems, improper maintenance can lead to corrosion and material damage. Monitoring pH and aeration levels prevents coolant from becoming caustic and attacking protective surfaces like paint or rubber. Strong odors often indicate bacterial overgrowth—a warning sign that immediate action is needed.

Plan Operations with Motor Efficiency in Mind

Consider how much your motors contribute to daily operations. Simple preventive measures, from choosing tested motors to optimizing placement and coolant maintenance, can save significant costs and reduce downtime. Investing time in these best practices ensures your motors deliver consistent performance while protecting your bottom line.

Mounting and Its Impact on Performance

The way you mount a servo motor directly impacts its performance, lifespan, and overall system efficiency. Paying attention to proper mounting can prevent costly issues and optimize operational output. Key benefits include:

- Vibration control– Poor servo motor mounting amplifies vibration, which can compromise precision and reduce the accuracy of motion. Properly secured motors minimize these risks.

- Cooling efficiency– Correct mounting ensures cooling systems work effectively, prolonging motor life and preventing overheating-related failures.

- Alignment accuracy– Misaligned motors impair servo positioning, reducing repeatability and consistency in automated processes.

- Operational stability– Stable mounting prevents movement under load, supporting smooth operation and reliable performance.

In applications such as robotics, servo-driven packaging machines, or servo control system manufacturing, investing in precise servo motor mounting enhances motion control efficiency, reduces maintenance needs, and safeguards your equipment investment.

Types of Servo Motor Mounting Methods

Choosing the right servo motor mounting method is crucial for achieving optimal motion control, efficiency, and long-term reliability. Each mounting type offers distinct advantages and considerations depending on your application.

1. Face Mounting

Face mounting secures the motor flange directly to the machine frame.

Advantages:

Provides a strong and rigid connection.

Ideal for servo motion control systems that demand high stability and rigidity.

Disadvantages:

Limited flexibility for position adjustments.

2. Foot Mounting

Foot mounting attaches the motor to a base plate using feet or brackets.

Advantages:

Simple to install and maintain.

Well-suited for servo systems in conveyor belts and automated equipment.

Disadvantages:

May require extra space, making it less suitable for compact designs.

3. Shaft Mounting

Shaft mounting mounts the motor directly onto the driven shaft without additional couplings.

Advantages:

Reduces misalignment issues.

Perfect for space-constrained setups in digital servo control systems.

Disadvantages:

Requires precise machining to avoid stress on the motor shaft.

4. Bracket Mounting

Bracket mounting uses custom brackets to position the motor at specific angles or orientations.

Advantages:

Offers flexibility for complex servo positioning control systems.

Commonly used in servo systems of robotics and packaging machines.

Disadvantages:

Custom fabrication can increase costs.

5.Effect of Servo Motor Mounting on Key Performance Factors

Accuracy

Stable mounting is essential for maintaining servo positioning precision, especially in systems with feedback control.

Vibration and Noise

Proper mounting reduces vibration, ensuring smoother, quieter operation in industrial servo control systems.

Thermal Management

Good mounting promotes airflow and effective cooling, extending the service life of both the servo motor and drive system.

Maintenance

Certain mounting styles make inspection, servicing, and component replacement easier, which is critical for efficient operation in manufacturing servo systems.

Tips for Optimizing Mounting

Proper installation is critical to maximize the performance, reliability, and lifespan of your servo motor and servo motion control system. Following these best practices ensures smooth operation and reduces costly downtime:

- Align the motor precisely– Use precision alignment tools to install the servo motor squarely, minimizing misalignment and improving servo positioning accuracy.

- Reduce vibration and noise– Apply vibration damping pads, especially in sensitive servo motion control systems, to ensure quiet, stable operation.

- Optimize cooling– Provide adequate ventilation to enhance heat dissipation in AC servo motor control systems, extending motor and drive system longevity.

- Secure fasteners correctly– Follow manufacturer-recommended torque specifications to prevent bolts from loosening, maintaining stability and safety.

- Verify system stability– After installation, check the stability of your test setup, particularly for multi-axis servo control systems, to guarantee reliable performance under load.

Common Mistakes to Avoid

Proper installation is critical for ensuring your servo system operates efficiently and reliably. Avoiding these common mistakes can prevent unnecessary wear, downtime, and costly repairs:

- Misalignment– Misaligned components reduce the efficiency of servo systems in CNC machines and accelerate mechanical wear, compromising long-term performance.

- Insufficient support– Failing to provide proper mounting or structural support can lead to instability, especially in high-speed applications such as servo systems in conveyor belts.

- Over-tightening bolts– Excessive torque can damage the housing of servo systems in automation equipment, leading to premature failure and costly replacements.

Real-World Applications

Selecting the appropriate servo motor mounting method can significantly enhance servo system performance, reduce maintenance, and improve operational efficiency across various industries:

- CNC Machining– Face mounting ensures precise alignment and high accuracy, making it ideal for servo systems in cutting and milling operations.

- Robotics– Bracket mounting enables flexible joint positioning, optimizing movement and control in servo systems used in robotics applications.

- Packaging Lines– Foot mounting simplifies installation and maintenance, supporting reliable performance in servo systems of packaging machines.

- Material Handling– Shaft mounting delivers compact and efficient power transfer, making it perfect for servo systems on conveyor belts where space is limited.

Why Precision CNC Machining Matters for Servo Motor Housings?

Overview of CNC Motor Housing Machining

CNC machining of motor housings is a precision manufacturing process designed to produce durable, high-performance enclosures for electric motors, servo motors, and industrial automation systems. These motor housings form the structural backbone, protecting internal components while enabling efficient thermal management, minimizing vibration, and ensuring accurate assembly alignment.

For applications such as electric vehicles (EVs), energy storage systems, or industrial power solutions, precision-engineered CNC machined battery enclosures are critical. They ensure optimal performance, safety, and long-term reliability in demanding environments.

Material Options:

Choose from high-strength aluminum (6061, 7075) or stainless steel (304, 316) for battery enclosures, providing excellent structural integrity, corrosion resistance, and durability for harsh operational conditions.

Superior Heat Dissipation:

Well-designed CNC machined aluminum battery boxes facilitate efficient thermal management, helping maintain battery performance, prevent overheating, and enhance safety in EVs and energy storage applications.

Tight Tolerances and Custom Fit:

With machining tolerances as tight as ±0.01 mm, custom battery housings can be precisely fitted for modules, BMS (Battery Management Systems), connectors, and thermal insulation layers, ensuring seamless integration.

Durability and Protection:

These enclosures are engineered to withstand industrial stress, offering impact resistance, vibration isolation, and waterproof sealing where necessary, making them ideal for industrial automation machinery and high-performance motor systems.

Optional Finishes:

Enhance both aesthetics and corrosion resistance with anodizing, powder coating, or custom laser engraving, providing traceability and branding opportunities.

Key Features of CNC Machined Motor Housings

Investing in precision CNC machining for motor housings ensures superior performance, durability, and reliability in electric motors, servo motors, and industrial automation systems. Key advantages include:

- High Dimensional Precision– Achieve exact fitting and assembly with tight machining tolerances up to ±0.01 mm, ensuring optimal servo motor alignment and consistent motion control.

- Material Options– Select from aluminum (6061, 6082, 7075), stainless steel (304, 316), as well as copper or cast iron, providing flexibility for various performance and environmental requirements.

- Customized Design– Support for OEM/ODM motor housing designs, including cooling fins, mounting holes, grooves, and other application-specific features.

- Excellent Surface Finish– Enhance durability, corrosion resistance, and aesthetics with anodizing, powder coating, electropolishing, sandblasting, or passivation.

- Thermal & Structural Optimization– Improve heat dissipation, vibration resistance, and overall durability to ensure reliable operation in demanding industrial or automotive environments.

CNC Machining Capabilities and Precision Tolerances

We provide CNC machining services for precision CNC motor housings (servo motor enclosures) used in industrial automation, smart equipment, and precision machinery. Using 5-axis CNC milling and turn-mill compound machining, we achieve key tolerances of ±0.005 mm and flatness/coaxiality ≤0.01 mm. Parts up to 1200mm × 800mm × 600mm are supported, with files in STEP, STP, IGS, DWG, DXF, or PDF. Surface finishing includes anodizing, electroplating, painting, and powder coating, while quality is ensured via CMM inspection, FAI, and RoHS compliance. From drawing optimization to prototype sampling and mass production, we deliver full-chain custom motor housing solutions efficiently.

| Capability / Parameter | Specification / Details | Notes |

| Core Product | CNC Motor Housing (Servo Motor Enclosure) | Custom housing for automation equipment |

| Machining Services | CNC milling, CNC turning, 4-axis & 5-axis | Accurate complex cavities & structures |

| Tolerance | ±0.005 mm; flatness/coaxiality ≤0.01 mm | Precision for servo motor assembly |

| Max Part Size | 1200mm × 800mm × 600mm | Supports large precision parts |

| Formats | STEP, STP, IGS, DWG, DXF, PDF | Compatible with design workflow |

| Materials | Aluminum (6061/7075); Stainless Steel (304/316) | Lightweight and durable |

| Surface Finishing | Anodizing, Electroplating, Painting, Powder Coating | Enhanced durability & appearance |

| Quality Control | CMM, FAI, RoHS | Ensures compliance and reliability |

| Process | Drawing → Prototype → Mass Production | Full-chain custom CNC solutions |

Applications in Industrial Automation and Multi-Industry Equipment

Our custom machined motor housings are engineered for diverse applications across multiple industries. From electric vehicle drive motors to servo and stepper motors, they ensure precision and durability. Additionally, these housings excel in robotics and automation systems, fan motors and blower units, medical diagnostic equipment, industrial AC/DC motors, as well as smart appliances and HVAC systems. Whether your project involves high-speed motor applications or heavy-duty industrial use, these solutions consistently deliver superior performance, long-lasting reliability, and the adaptability required for modern equipment demands.

Choosing the Right Servo Motor and Housing

Comparing AC, DC, and Synchronous Servo Motors

Understanding the advantages of AC servo motors compared to other motor types is essential for selecting the right solution for precision and automation applications. Unlike stepper motors, AC servo motors deliver smoother, more accurate motion control, excelling in high-speed and high-torque tasks, while stepper motors are more cost-effective but less precise, often used in 3D printers or entry-level CNC machines. When compared with induction motors, AC servo motors provide superior speed control, dynamic response, and precision, whereas induction motors prioritize robustness and affordability for applications like pumps, conveyors, and heavy-duty industrial equipment.

The differences between AC servo motors and DC servo motors further highlight their distinct advantages. AC servo motors operate with alternating current, often incorporating permanent magnets for high efficiency, precise control, and consistent torque across a wide speed range. They offer higher efficiency (85–95%), low maintenance, long lifespan, and superior control precision, making them ideal for robotics, CNC machinery, and advanced motion control systems. In contrast, DC servo motors rely on brushes and commutators, offering simpler integration and lower initial cost but lower efficiency (70–85%), higher maintenance, shorter lifespan, and reduced precision at higher speeds, limiting their use to small automation tasks or hobby projects.

Whether your application demands high-speed motion, heavy-duty industrial performance, or precision positioning, choosing the right servo motor type ensures optimal performance, reliability, and cost-effectiveness over the long term.

Cost Considerations

When evaluating AC servo motors for your applications, understanding the total cost of ownership is crucial. The purchase price varies depending on motor size, power rating, and features such as closed-loop control or high torque density, with premium brands often commanding higher prices. Beyond the initial investment, installation costs include mounting hardware, electrical connections, and professional setup to ensure optimal performance. Regular maintenance is essential to extend motor life, covering tasks like lubrication, bearing inspections, and checking electrical connections.

Energy efficiency also impacts long-term expenses, as AC servo motors consume power based on their rating and operating duration, making energy-efficient models with advanced management systems more cost-effective. Over time, spare parts such as bearings, brushes, and encoders may require replacement, and their availability affects overall cost. Additionally, downtime costs from unexpected failures or maintenance delays can impact productivity and revenue, emphasizing the importance of high-quality components and routine servicing. Finally, investing in upgrades and modifications—including enhanced control systems, improved feedback devices, or integration with the latest automation technologies—can increase upfront costs but ultimately deliver higher performance, precision, and efficiency.

Why Choose Welleshaft as Your Precision Servo Motor Housing Partner?

Servo performance starts with the housing. A 0.01 mm mounting deviation can cause feedback errors, torque ripple, or premature failure. Welleshaft eliminates that risk.

We deliver ±0.005 mm positioning tolerance and ≤0.01 mm flatness. Every housing, from complex liquid-cooled enclosures to thin-wall robotic joints, maintains micron-level consistency across parts up to 1200 mm.

We optimize materials and thermal performance. Based on your application, we recommend the right aluminum or stainless steel grade. Our topology-optimized cooling fins and vacuum brazing improve thermal conductivity by over 30%.

We handle the full cycle. Prototypes in 24 hours. Small batches in 7 days. Surface finishing from anodizing to IP67-sealed coatings—all in-house. Secondary precision work on threads and sealing grooves ensures protection never fails.

Every part is traceable. Full CMM inspection, material certificate, and RoHS compliance included.

Not just a supplier. Your engineering partner.

FAQ

What might cause a servo motor to hum or vibrate without rotating?

This issue often stems from mechanical binding, an overloaded condition, incorrect wiring, or a malfunctioning drive. It is advisable to verify all connections and the mechanical load before attempting a restart.

Do servo motors use brushes or are they brushless?

Modern industrial servo motors are predominantly brushless, offering better efficiency and longer service life. Brushed versions, however, remain common in cost-sensitive or simpler applications.

What exactly is the inertia ratio in servo systems?

It refers to the ratio between the load inertia and the rotor inertia. For stable performance, a ratio near 1:1 is ideal, though values up to 5:1 may still be acceptable depending on the application.

Are servo motors AC or DC powered?

Servo motors can be designed to operate on either AC or DC supply, with the choice depending on the specific requirements of the application and system architecture.

Contributed by the Welleshaft Engineering Team, led by Mr. Xu. Decades of experience in precision CNC machining for servo motor housings across automation, robotics, and CNC. Behind every drawing, our engineers optimize for manufacturability and long-term reliability.