1.Ultimate Guide to Busbar Products: Types, Applications, Manufacturing & Buying Tips

At Welleshaft, we understand the critical role busbar products play in efficient and safe power distribution. This Ultimate Guide to Busbar Products is designed for professionals who want to buy high-quality busbar products online or seek expert advice on custom busbar manufacturing, covering everything from types and applications to manufacturing and buying tips.

2.What Are Busbar Products?

The Ultimate Guide to Busbar Products highlights their role as essential components in electrical power distribution systems, designed to conduct and distribute large currents safely and efficiently. Typically made from conductive metals like copper or aluminum, busbars come in various forms including bare bars, insulated bars, and modular trunking systems. They reduce power loss, improve system reliability, and simplify complex wiring compared to traditional cable solutions. Welleshaft specializes in supplying and customizing high-quality busbar products tailored to diverse industrial applications.

3.How Busbar Products Work: Basic Principles and Types

Busbars function as centralized electrical conductors, distributing electricity from power sources to outgoing circuits. Their broad, flat design offers low electrical resistance and excellent heat dissipation. The main types include:

- Copper Busbar:Known for excellent conductivity and durability.

- Aluminum Busbar:Lightweight and cost-effective alternative.

- Insulated Busbar:Enhanced safety with protective insulation layers.

Each type supports specific applications depending on current load, environmental conditions, and safety requirements.

4.Busbar Manufacturing Process Explained: The Ultimate Guide to Busbar Products

At Welleshaft, we ensure that every busbar product meets stringent quality standards. The manufacturing process includes:

- Material Procurement:High-purity copper or aluminum sourced from certified suppliers.

- Cutting and Shaping:Precision laser cutting and CNC bending tailored to design specs.

- Surface Treatment:Anti-corrosion coatings or anodizing for aluminum busbars.

- Insulation Application:For insulated busbars, application of dielectric layers and sleeves.

- Assembly and Testing:Mechanical assembly followed by electrical testing for conductivity, insulation resistance, and load capacity.

Quality control includes compliance with ISO 9001 and IEC electrical standards. Our partner factories use advanced equipment like CNC bending machines, robotic welding, and high-precision measuring instruments.

5.Types of Busbar Products: Copper, Aluminum, and Insulated Busbars

Choosing between a copper busbar and an aluminum busbar depends on your project’s conductivity, weight, and cost requirements. Copper offers superior conductivity and durability but comes at a higher price, whereas aluminum is lightweight and more affordable. Our detailed comparison of copper busbar vs aluminum busbar explains these differences in depth.

For enhanced safety, insulated busbar products protect against electrical faults and short circuits, making them ideal for switchgear and sensitive industrial environments. You can explore custom insulated busbar manufacturing services to tailor solutions for your facility.

7.Essential Busbar Components and Custom Solutions

From connectors to mounting hardware, busbar components are critical for system compatibility and performance. Need to buy busbar components for electrical panels or require custom busbar components manufacturing near you? Welleshaft offers fast delivery and expert advice on selecting compatible parts.

We also provide custom busbar design services for OEMs, helping you order tailored busbar products online with full design support.

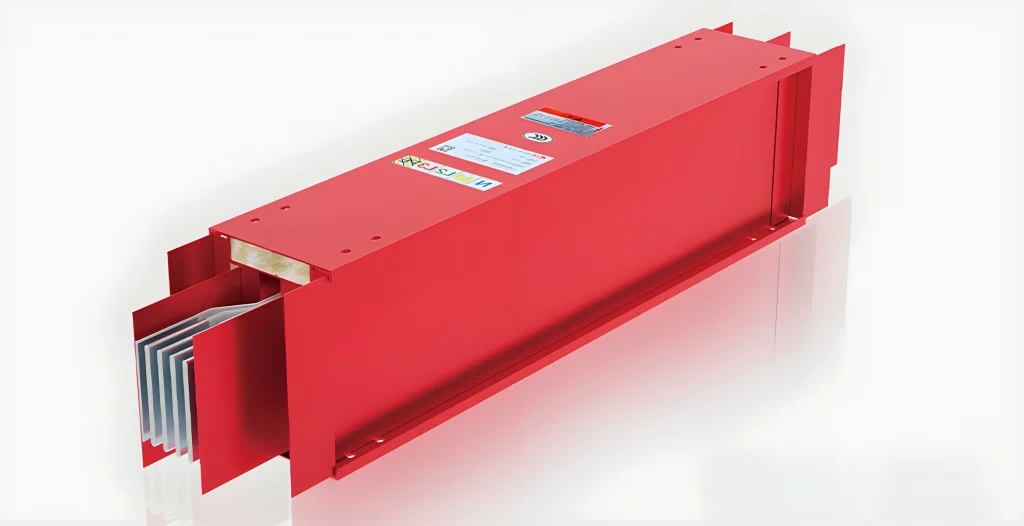

8.Busbar Trunking: What It Is and Why It Matters

Busbar trunking systems are modular assemblies that efficiently distribute power across large industrial buildings. Wondering what is busbar trunking and how it works? These systems simplify installation and maintenance, offering flexible scalability.

Our experts can help you buy busbar trunking for industrial buildings and provide maintenance advice to extend system lifespan.

9.Advantages of Electrical Busbar Products in Modern Systems

Electrical busbars come in various types, each meeting different standards and applications. We address common defects in electrical busbar products and how to avoid them through proper selection and maintenance.

Looking for a reliable electrical busbar price guide for contractors? Welleshaft offers competitive pricing combined with quality assurance.

10.How to Choose the Right Busbar Products for Industrial Applications

Selecting the perfect busbar product involves assessing current rating, material, environmental factors, and regulatory standards. Our custom busbar solutions optimize power distribution for industries ranging from manufacturing to data centers.

Contact us to discuss your needs and discover the benefits of custom busbar solutions for power distribution tailored to your facility.

11.Common Applications and Industry Use Cases

Busbar products power a wide range of sectors:

- Power Distribution:Utility grids and switchgear assemblies rely on busbars for efficient energy flow.

- Data Centers:High-density busbar systems support critical uptime and scalable power demands.

- Manufacturing Plants:Custom busbar solutions optimize complex industrial power requirements.

- Transportation:Electric vehicles and rail systems incorporate insulated busbar systems for safety.

Customer Case: Welleshaft recently delivered a custom copper busbar system for a leading European data center, improving power efficiency by 15% and reducing installation time by 20%.

12.Why Choose Welleshaft for Busbar Products?

Certified Quality: ISO 9001 and IEC compliance guarantees reliable, safe products.

Custom Solutions: Tailored busbar manufacturing and design services to fit unique project needs.

Technical Expertise: Our engineering team has 10+ years in electrical systems and busbar technology.

Advanced Manufacturing Partners: Equipped with CNC bending, laser cutting, and automated assembly lines.

Global Reach: Fast delivery and installation support worldwide, including local consultation services.

13.Detailed Comparison: Copper Busbar vs Aluminum Busbar

| Feature | Copper Busbar | Aluminum Busbar |

| Electrical Conductivity | Excellent (highest) | Good (~61% of copper) |

| Weight | Heavy | Lightweight |

| Cost | Higher | Lower |

| Corrosion Resistance | High (with coatings) | Moderate (requires treatment) |

| Application Areas | High current, switchgear | Cost-sensitive, lightweight designs |

This comparison helps buyers select the right busbar product based on performance and budget.

14.FAQs About Busbar Products

(1)How long does a typical copper busbar last?

A: With proper maintenance, copper busbars can last over 30 years in industrial settings.

(2)Are insulated busbars safer than bare busbars?

A: Yes, insulated busbars reduce risks of accidental contact and short circuits.

(3)What standards govern busbar manufacturing?

A: IEC 61439 and UL 857 are common standards for busbar systems and safety.

(4)Can Welleshaft customize busbars for unique power needs?

A: Absolutely, we offer full custom busbar design and fabrication services tailored to your specifications.

Welleshaft specializing in busbar systems and power distribution. With over 8 years of experience, has helped numerous industrial clients optimize their electrical infrastructure through advanced busbar technology and quality manufacturing processes.