1.Insulated Busbar Products: Safety and Performance Advantages

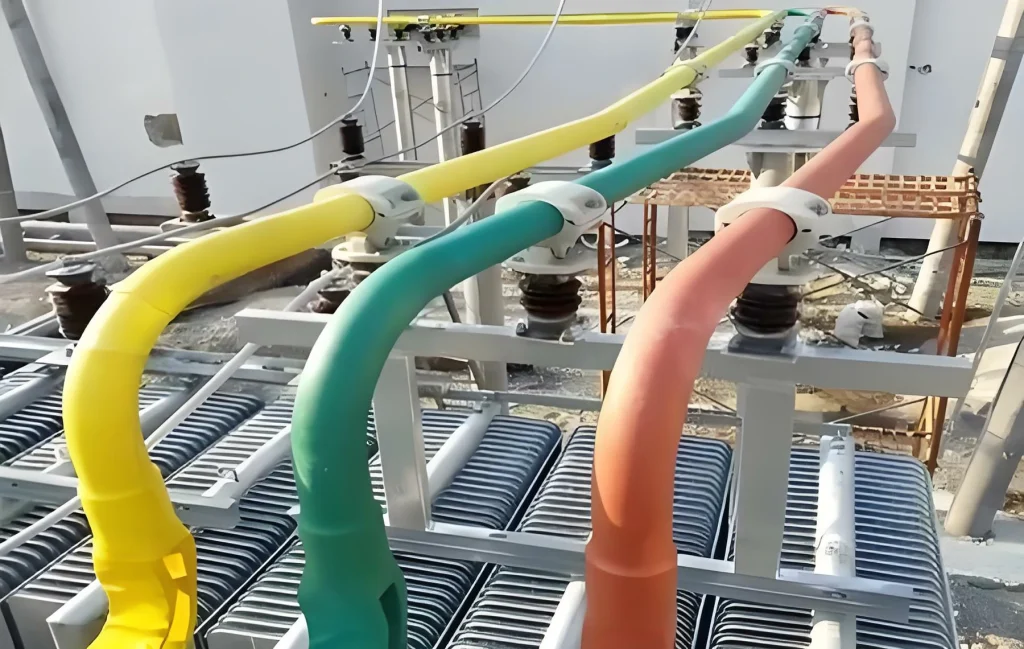

In modern power distribution systems, busbar products play a crucial role in delivering efficient and reliable electricity. From copper busbar to aluminum busbar designs, manufacturers have continually improved busbar components to meet the demands of industrial and commercial facilities. Among these innovations, Insulated Busbar Products have become a leading solution, offering unmatched safety, performance, and durability for today’s critical power applications.

For businesses looking to buy insulated busbar products for electrical safety, these solutions are not just about current conduction—they are about protecting equipment, ensuring compliance with international standards, and reducing long-term maintenance risks.

2.What Are Insulated Busbar Products?

An insulated busbar is an electrical busbar system designed with an additional insulation layer that protects against short circuits, electrical leakage, and accidental contact. Unlike bare busbar trunking systems, insulated designs are manufactured with high-grade insulation materials to improve electrical safety and reliability.

These solutions are widely used in:

1.Switchgear assemblies requiring cost-effective insulated busbar systems

2.Data centers where buyers often ask “Where to purchase insulated busbar for data centers?”

3.Industrial electrical panels that demand enhanced safety for operators

4.Renewable energy systems requiring durable insulated busbar solutions for harsh environments

3.Safety Benefits of Insulated Busbar Products

1. Protection Against Electrical Faults

One of the top safety benefits of insulated busbar products is their ability to prevent electrical faults and short circuits. The insulation acts as a barrier, reducing the likelihood of arc flash incidents.

2. Improved Operator Safety

In facilities where workers handle busbar components during installation or maintenance, insulated designs reduce the chance of accidental electric shock.

3. Compliance with Global Standards

Leading insulated busbar suppliers with UL and IEC certifications ensure products meet rigorous international safety benchmarks. These certifications are critical for companies seeking custom insulated busbar solutions for industrial applications.

4.How Insulated Busbars Improve System Performance

1. Thermal Management

Insulated busbar products with thermal protection features maintain safe operating temperatures by minimizing heat build-up.

2. High Voltage Capability

The insulation layer allows busbars to operate in high-voltage applications without compromising safety.

3. Reduced Energy Losses

Compared with bare busbars, insulated options reduce energy leakage, improving overall electrical busbar system performance.

5.Materials Used in Insulated Busbar Manufacturing

During busbar manufacturing, insulation materials are carefully selected for thermal endurance and dielectric strength. Common materials include:

| Insulation Material | Properties | Applications |

| Epoxy Resin | High thermal resistance | Industrial switchgear |

| PVC/Polyolefin | Cost-effective, durable | Electrical panels |

| Silicone Coating | Flexible, high dielectric strength | Harsh environments |

These materials ensure that insulated busbar products designed for electrical panel safety last longer and withstand extreme operational conditions.

6.Standards and Certifications for Insulated Busbar Products

When choosing insulated busbar suppliers with UL and IEC certifications, buyers should look for:

1.UL 857 (Busways and Busbar Trunking Systems)

2.IEC 61439 (Low-voltage switchgear and control gear assemblies)

3.RoHS/REACH compliance for environmentally safe materials

These certifications guarantee insulated busbar manufacturing services with quality assurance and reduce the risk of non-compliance penalties.

7.Installation and Maintenance of Insulated Busbar Systems

(1)Safe Installation Guidelines

1.Always use certified custom busbar components.

2.Ensure proper grounding and alignment during busbar trunking installation.

3.Follow the manufacturer’s manual for torque and clearance values.

(2)Maintenance Practices

1.Regular thermal scanning to detect overheating.

2.Visual inspection for cracks in insulation.

3.Replacement schedules based on operational environment (typically 20–30 years).

This aligns with common industry questions such as “What maintenance is required for insulated busbar systems?” and “How long do insulated busbar products typically last?”

8.Comparing Insulated vs. Bare Busbars

| Feature | Bare Busbar | Insulated Busbar |

| Electrical Safety | Low | High |

| Risk of Short Circuit | High | Low |

| Compliance with UL/IEC Standards | Limited | Strong |

| Lifespan | 10–15 years | 20–30 years |

| Best Application | Low-risk, low-cost setups | High-performance, critical systems |

This answers a common query: “Are insulated busbars better than bare busbars for power distribution?” The evidence strongly favors insulated solutions in safety-critical applications.

9.Industrial Applications of Insulated Busbar Products

1.Data Centers – For compact, efficient, and safe power distribution.

2.Renewable Energy Plants – Withstand harsh outdoor conditions.

3.Manufacturing Facilities – Reduce downtime due to electrical faults.

4.Electrical Panels in Buildings – Provide cost-effective insulated busbar systems for switchgear.

10.Why Choose Welleshaft for Insulated Busbar Solutions?

At Welleshaft, we specialize in custom insulated busbar solutions for industrial applications. Our engineering team offers:

1.High-performance insulated busbar products for power distribution

2.Durable insulated busbar solutions for harsh environments

3.Insulated busbar products with thermal protection features

4.Tailored busbar manufacturing services with ISO, UL, and IEC certifications

By partnering with Welleshaft, clients receive both technical expertise and reliable busbar systems that ensure safety and performance.

This article was written by a senior electrical engineer from Welleshaft, with over 8 years of experience in busbar manufacturing and industrial power distribution systems. Having worked on projects across Asia, Europe, and North America, the author brings hands-on expertise in designing custom busbar systems that meet UL and IEC compliance standards.