Rill Rolling for Sale: A Comprehensive Guide to Ring Rolling and Rolled Ring Forging

Rill rolling might not be a widely recognized term, but it often refers to the detailed and technical aspects of ring rolling and rolled ring forging. These processes are pivotal in creating high-quality metal rings used across various industries. This article provides an in-depth look into these manufacturing techniques, their processes, and considerations for purchasing rolled rings.

Section 1: Introduction

1.1. What is Rolled Ring Forging?

Rolled ring forging is a manufacturing process used to create high-strength, precision-engineered rings. It involves heating a metal billet to a malleable state and then shaping it into a ring using specialized machinery. This process enhances the material’s mechanical properties, making it ideal for applications requiring durability and strength.

1.2. What is the Rolling Process in Forging?

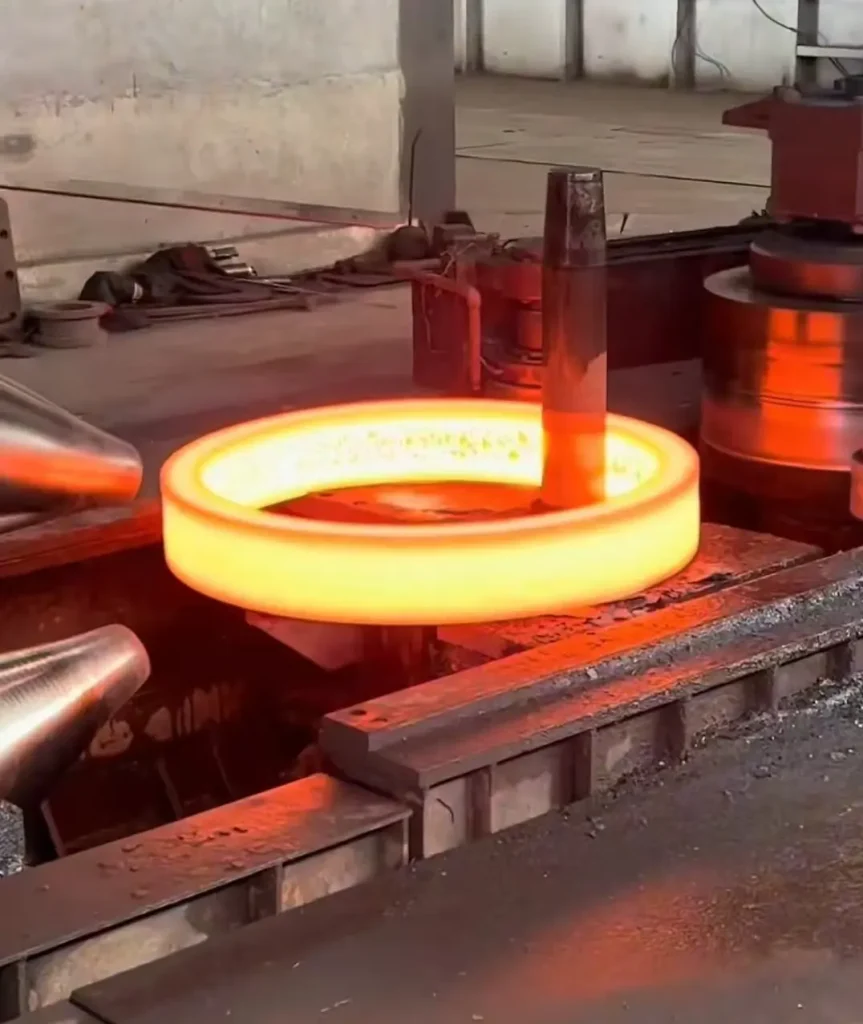

The rolling process in forging deforms a metal billet into a desired shape using rolling mills. In forming rings, manufacturers heat the billet and pass it through a series of rollers that apply pressure to expand and shape it into a ring. This method lets them precisely control the ring’s dimensions and properties.

1.3. What is the Process of Ring Rolling?

The process includes several key steps:

-

Heating: Operators heat the metal billet to a temperature that makes it malleable, typically above 50% of the metal’s melting point.

-

Preforming: Technicians shape the heated billet into a rough ring form using initial forming techniques.

-

Rolling: Machines apply pressure via rollers to the preformed ring, expanding and refining it to its final dimensions.

-

Finishing: After rolling, manufacturers perform additional treatments such as machining or heat treatment to meet specific requirements.

Section 2: What is the Difference Between Roll Forging and Ring Rolling?

Roll forging and ring rolling serve different purposes in forging:

-

Roll Forging: Operators reduce the cross-sectional area of a metal billet by passing it through rollers that apply compressive forces. They typically use this process to produce elongated shapes like bars or rods.

-

Ring Rolling: Manufacturers focus on creating ring-shaped components by rolling the billet to form a ring with precise dimensions. They use specialized machines and techniques to achieve the desired properties.

2.1. Advantages of Ring Rolling

Ring rolling offers several advantages:

- High Strength: The process produces rings with enhanced mechanical properties due to the refined grain structure.

- Precision: Ring rolling machines can achieve tight tolerances and accurate dimensions.

- Seamless Construction: The rings are produced without seams or joints, which enhances their strength and reliability.

2.2. Disadvantages of Ring Rolling

Ring rolling does have some drawbacks:

- High Initial Costs: The equipment and setup for ring rolling can be expensive.

- Specialized Equipment:The process requires specific machinery that may not be suitable for other types of forging.

2.3. Applications of Rolled Rings

Rolled rings are used in a variety of applications, including:

- Aerospace:Bearings, flanges, and structural components.

- Automotive: Gear rings, camshafts, and crankshafts.

- Energy:Seals, connectors, and valves for oil and gas industries.

3: Seamless Rolled Ring Forging Process

The seamless rolled ring forging process refers to the production of rings without welding or joining. This is achieved by using a continuous billet that is rolled into the final shape, eliminating the need for additional joining processes. The seamless nature of these rings enhances their strength and durability, making them ideal for high-stress applications.

3.1.Seamless Rolled Ring Forging Process

The seamless rolled ring forging process involves several critical steps:

3.1.1.Billet Preparation:

- Selection:Choose a metal billet based on the required properties of the final ring. Common materials include steel, alloy steel, and titanium.

- Heating:Heat the billet to a temperature that makes it malleable. This temperature typically ranges between 800°C and 1200°C (1470°F to 2190°F), depending on the metal being used.

3.1.2.Preforming:

- Initial Shaping:The heated billet is preformed into a rough ring shape. This step often involves using a preforming press to achieve an initial approximation of the final dimensions.

3.1.3.Ring Rolling:

3.1.4.Finishing:

- Heat Treatment:After rolling, the ring may undergo heat treatment to enhance its mechanical properties, such as strength and hardness.

- Machining: Final machining processes may be applied to achieve precise dimensions and surface finish.

3.1.5.Inspection and Testing:

- Quality control teams perform rigorous checks on the finished rings, including dimensional inspection and non-destructive testing, to ensure they meet the required specifications.

3.2. Key Considerations When Choosing Seamless Rolled Ring Forging

- Material Selection: Engineers choose the appropriate metal alloy based on the performance requirements of the final ring.

- Process Parameters: Technicians optimize the heating, rolling, and finishing processes for the specific material and ring dimensions.

- Supplier Expertise: Companies collaborate with experienced manufacturers who have the necessary equipment and knowledge to produce high-quality seamless rolled rings.

- Cost and Lead Time: Buyers consider the cost of the forging process and the lead time for production, especially when custom rings are required.

Section 4: Ring Rolling Forging Machine

A ring forging machine is specialized equipment used to shape metal into rings. These machines come in various types, including:

-

Horizontal machines: Used for larger rings and high-volume production.

-

Vertical machines: Suitable for smaller rings and high-precision applications.

Engineers design these machines to handle different materials and sizes, enabling versatile production capabilities.

Section 5: Rolled Ring Forging Suppliers and Manufacturers

When searching for rolled ring forging suppliers or rolled rings manufacturers, consider the following:

Experience: Choose suppliers with a proven track record in ring rolling and forging.

Capabilities: Ensure they offer the necessary forging processes and have the right equipment.

Quality: Look for manufacturers that adhere to strict quality control standards and provide detailed product specifications.

Requesting quotes and reviewing the supplier’s past projects can help you find the best fit for your needs.

See what today’s rolled ring forging manufacturing does for businesses. Contact us for additional information and the best advice.

Section 6: Differences Between Forging and Rolling

Forging and rolling are two different metalworking processes

- Forging: The process shapes metal using compressive forces applied through methods like hammering or pressing. Forging improves the material’s strength and is suitable for producing high-stress components.

- Rolling: Involves reducing the thickness or changing the shape of metal by passing it through rollers.Manufacturers use rolling to produce various shapes, including sheets, plates, and rings.

- Thread Rolling, Shape Rolling, and Tube Rolling

In addition to ring rolling, other rolling processes include:

- Thread Rolling: Used to create threads on metal components.

- Shape Rolling:Used to produce complex cross-sectional shapes.

- Tube Rolling: Used to form tubes and cylindrical shapes.

Section 7: Frequently Asked Questions (FAQs) about Rill Rolling, Ring Rolling, and Rolled Ring Forging

1. Which is better, rolling or forging?

The choice between rolling and forging depends on the specific application:

- Forging enhances the material’s strength and is suitable for producing high-stress components.

- Manufacturers use rolling to produce various shapes, including rings, and control dimensions precisely. Ring rolling is ideal for creating high-quality rings with seamless construction.

2. What is the difference between roll forging and rolling?

Roll forging involves reducing the cross-sectional area of a metal billet by passing it through rollers, typically used for elongated shapes like bars or rods. Ring rolling is a specialized form of rolling that focuses on creating ring-shaped components with precise dimensions.

3. What is a ring roller used for?

A ring roller is used to shape metal into rings. This equipment is essential for the ring rolling process and ensures precise formation of rings with specific dimensions and properties.

4. What are rolled rings?

Manufacturers produce rolled rings by the ring rolling process. Users apply these rings in various fields because of their strength, durability, and precise dimensions.

5. What is the meaning of ring rolling?

Ring rolling refers to the process of shaping a heated metal billet into a ring form using rolling machines. It involves applying pressure to expand and refine the ring, resulting in a high-strength, precision-engineered component.

6. What are the differences between roll forging and rolling?

Roll forging reduces the cross-sectional area of a metal billet to produce elongated shapes, while rolling (including ring rolling) involves shaping the metal into various forms, such as rings. Roll forging typically focuses on lengthening materials, whereas rolling can produce a wide range of shapes and sizes.

7. What does forging a ring mean?

Forging a ring involves the process of shaping a metal billet into a ring form through forging techniques, often using heat and pressure. This method enhances the mechanical properties of the metal, resulting in a strong, durable ring.

8. What are rolling rings?

Metalworking processes roll rings to meet specific dimensional and strength requirements, using them in various applications across different industries.

9. What is the roll forging process?

The roll forging process involves shaping a metal billet by passing it through rollers that apply compressive forces.Manufacturers use this method to produce various shapes, including bars, rods, and sometimes rings.

10. What are rolled ring forging suppliers?

Rolled ring forging suppliers are companies that provide rolled rings and related forging services. They specialize in producing high-quality rings through the ring rolling process and often offer custom solutions to meet specific customer requirements.

11. What are rolled ring forging machines?

Specialized machines shape metal billets into rings through rolled ring forging.These machines apply pressure through rollers to achieve precise dimensions and are essential for the ring rolling process.

12. What is a rolled ring forging process PDF?

A rolled ring forging process PDF typically contains detailed documentation of the rolled ring forging process, including diagrams, step-by-step procedures, and technical specifications. It serves as a reference for understanding and implementing the process.

13. What are the different types of rolling processes?

Different rolling processes include:

Ring Rolling: Producing ring-shaped components.

Thread Rolling: Creating threads on metal parts.

Shape Rolling: Forming complex cross-sectional shapes.

Tube Rolling: Producing cylindrical shapes or tubes.

Conclusion

Understanding the intricacies of ring rolling and rolled ring forging can significantly impact your manufacturing decisions. By familiarizing yourself with the processes, equipment, and suppliers, you can make informed choices that ensure high-quality, durable ring components for your applications. Whether you need seamless rolled rings or specialized forged components, knowing the key differences and advantages of these processes will help you achieve the best results for your projects.

For those interested in roll forging, it’s important to find reliable suppliers and understand the processes and materials involved. Chinese professional forging manufacturer of Welleshaft often offer a range of roll forging services and can provide valuable insights into the latest techniques and materials.