The Ultimate Guide to Anodized Aluminum: Process, Benefits & Industrial Use | Welleshaft 1.Introduction: What Is Anodizing? How to anodize aluminum: Anodizing is an electrochemical process that enhances aluminum’s natural oxide layer. It improves corrosion resistance, surface hardness, and allows coloring for functional and decorative uses. Anodized aluminum is common in aerospace, construction, electronics, and […]

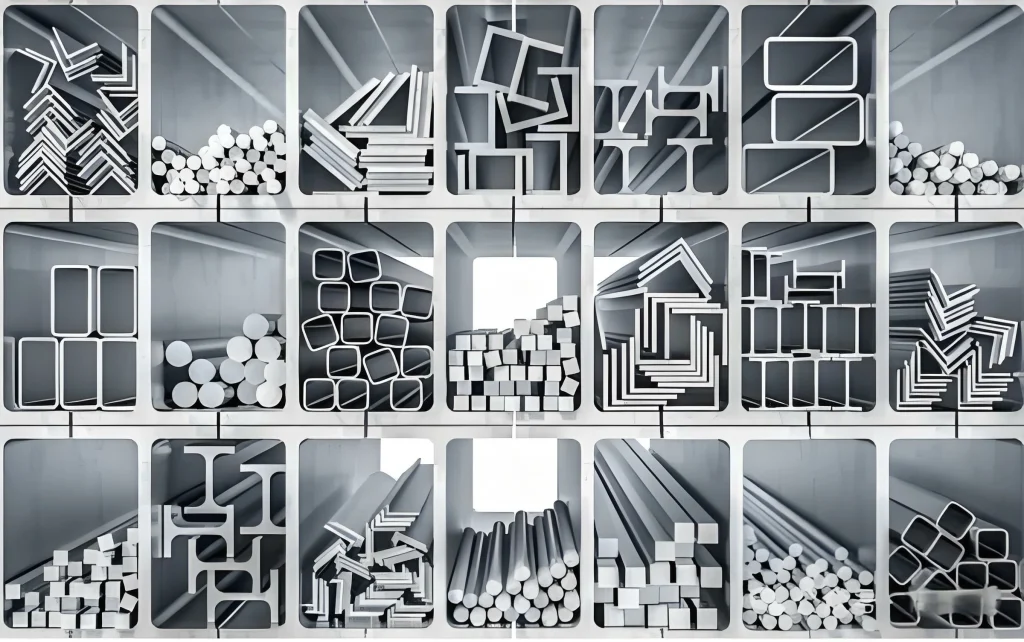

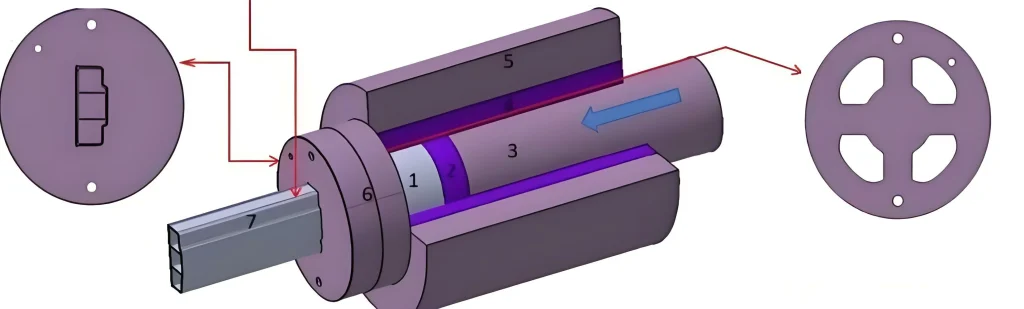

Aluminum Extrusion Services | Welleshaft 1.What Is Aluminum Extrusion? Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to produce continuous shapes with a uniform cross-section. At Welleshaft, we offer high-precision Aluminum Extrusion Services that ensure structural strength and aesthetic quality. Our process enhances performance, reduces weight, and improves corrosion resistance. […]

Surface Hardening & Steel Hardness Conversion: The Ultimate Guide | Welleshaft 1.Introduction: What Is Surface Hardening? Steel Surface Hardening is a specialized heat treatment method that enhances a metal’s wear resistance by modifying only its surface, while maintaining core ductility. This process is widely used in industries such as automotive, aerospace, machinery, and tool manufacturing. […]

Hot Rolled vs Cold Rolled Steel Surface Finish | Welleshaft 1.Introduction: What Is the Difference Between Hot and Cold Rolled Steel? Hot rolled and cold rolled steels are both essential materials in manufacturing, but they differ significantly in their production process, surface finish, mechanical properties, and applications. Understanding these differences in cold vs hot rolled […]

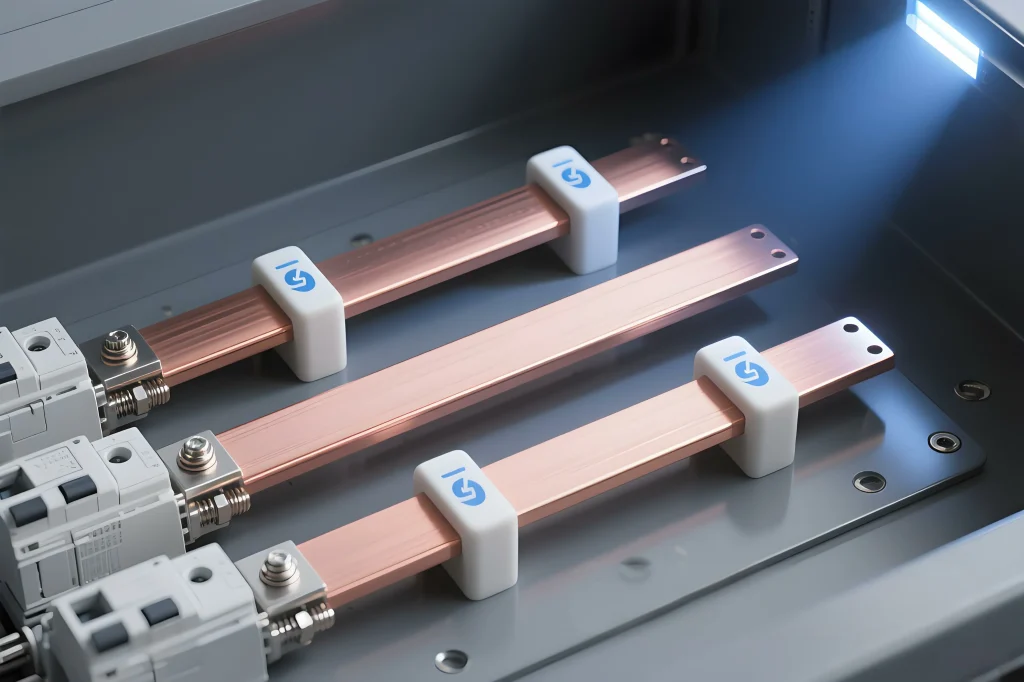

1.Introduction: What Are Plated Copper Bus Bars? Plated copper bus bars are solid conductors coated with metals like tin or silver to improve corrosion resistance, conductivity, and durability. These bus bars serve as central nodes for distributing power in systems ranging from EV batteries to electrical switchgear. At Welleshaft, we specialize in Tin Plated Copper […]

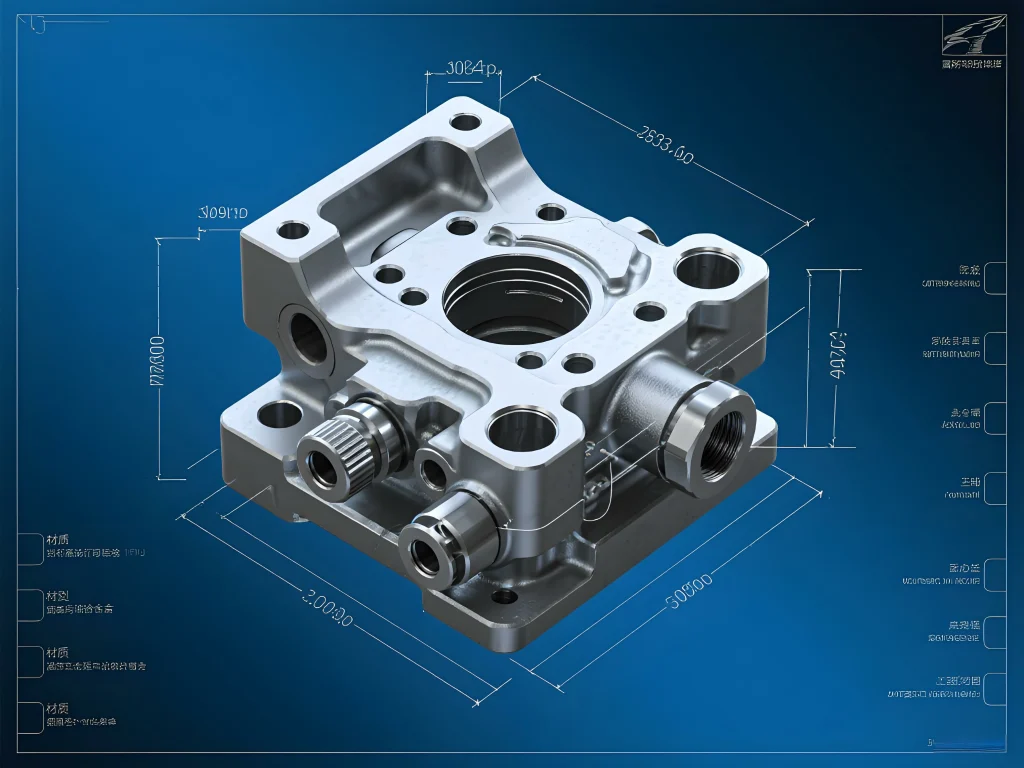

1.Military Investment Castings | Precision Defense Castings by Welleshaft Welleshaft has earned its place among ISO-certified Defense Castings manufacturers, trusted for delivering reliable, precision-built components used in mission-critical military and defense operations. With over six decades of hands-on experience supporting defense contractors, we build custom investment casting for military parts from a wide selection of […]

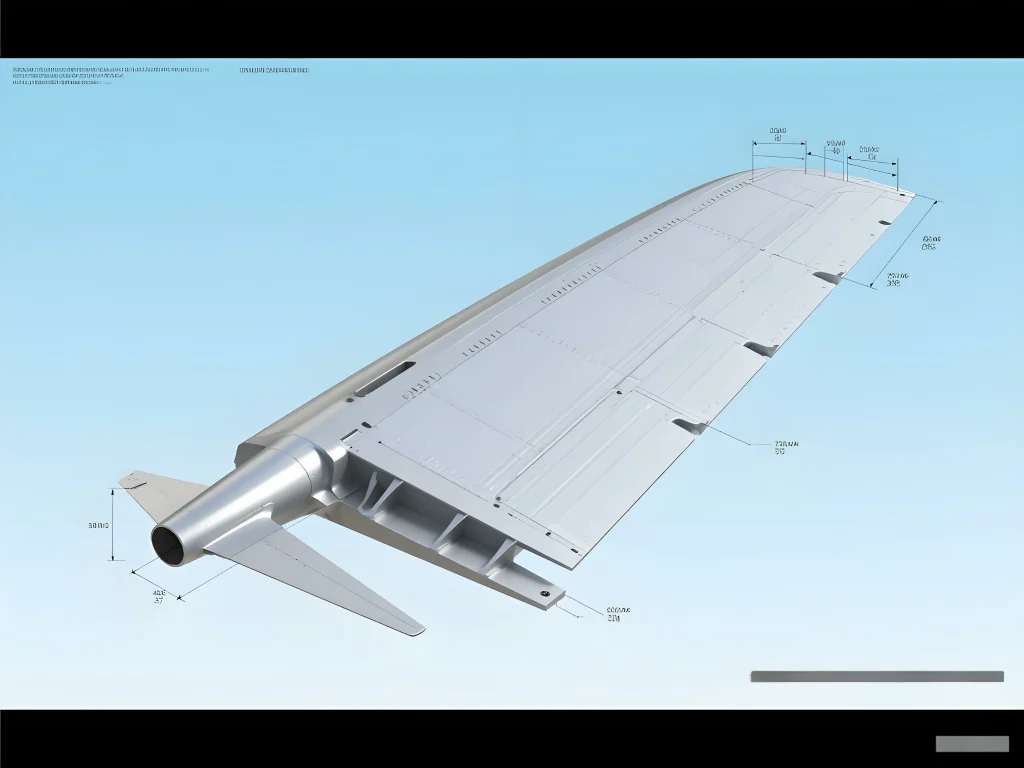

1.Aerospace Investment Castings | High-Precision Aerospace Component Casting by Welleshaft Welleshaft stands out among aerospace casting companies, offering dependable aerospace castings built for both commercial and defense aviation programs. With close to 40 years of hands-on experience, we handle investment casting for aerospace components using a wide set of high-temperature alloy castings for aerospace engines, like stainless […]

Sand Casting vs. Die Casting vs. Investment Casting: Choosing the Right Process for Your Parts Introduction: Understanding the Three Key Casting Methods Casting plays a pivotal role in modern manufacturing, especially for producing complex metal parts at scale—and Welleshaft’s custom metal casting services ensure each solution is tailored to your design, material, and volume requirements.. […]

1.Busbar Powder Coating & Bar Coatings Guide for Industrial and Energy Systems When it comes to busbar powder coating and bar coatings, choosing the right solution isn’t just about looks—it’s about long-term protection and electrical safety. Whether you’re dealing with High-Performance Busbar systems in switchgear, solar inverters, or marine control panels, the right coating can […]

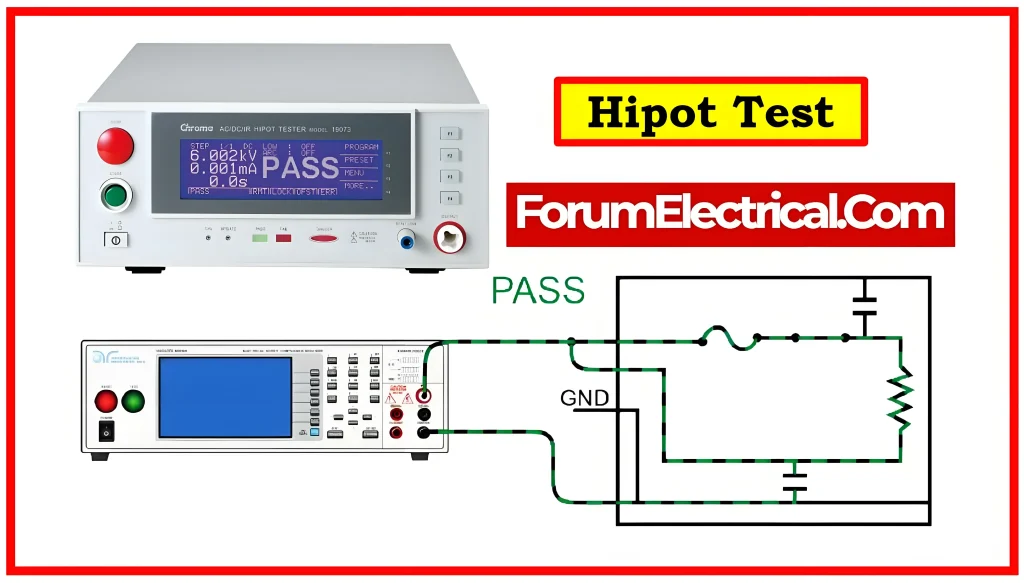

1.Best Practices for HiPot Testing of Busbars | Welleshaft High potential testing (commonly known as HiPot testing) is a vital electrical safety procedure used to validate insulation integrity in various electrical components. At Welleshaft, we implement best practices in HiPot testing to ensure our busbars and related systems meet rigorous international safety standards. This guide […]