1.Busbar Products Pricing Guide: Understanding Costs and Value

In the electrical and power distribution industry, busbar products are a critical investment—whether you’re installing in a high-rise, retrofitting an industrial plant, or upgrading electrical panels. From copper busbar and aluminum busbar options to insulated busbar and busbar trunking systems, our Busbar Products Pricing Guide helps you balance quality, durability, and budget to make the right choice.

Yet many electrical contractors, facility managers, and industrial buyers struggle with one big question: How much do busbar products cost, and how can I budget effectively? This guide offers a detailed busbar pricing guide for electrical contractors, explores what affects pricing, and provides strategies to get the best value busbar products suppliers near you—without sacrificing quality.

2.Why Understanding Busbar Pricing Matters

Buying busbars isn’t just about getting the lowest price. Your decision impacts:

1.Project timelines – Delays in sourcing or incorrect budgeting can hold up construction.

2.Electrical performance – Low-cost, substandard busbars can cause overheating or voltage drops.

3.Long-term costs – Higher upfront quality can save on repairs and downtime.

Whether you’re sourcing budget-friendly busbar solutions for electrical panels or getting a price quotation for bulk busbar product orders, a transparent pricing approach helps avoid surprises.

3.Factors That Affect the Price of Busbar Products

| Factor | Impact on Price | Example |

| Material type | Copper is more expensive than aluminum due to higher conductivity and durability. | Copper busbar: $12–$18/kg vs. Aluminum busbar: $4–$8/kg |

| Size & cross-section | Larger cross-sections require more raw material, increasing cost. | 100×10 mm busbar costs more than 50×5 mm |

| Insulation type | Insulated busbar systems have higher manufacturing complexity. | Epoxy-coated insulated busbar adds 15–25% to price |

| Custom vs. standard | Custom busbar manufacturing involves tooling, design, and setup costs. | may cost 30% more |

| Quantity ordered | Bulk purchasing reduces per-unit costs. | 500m order may save 10–20% compared to 50m |

| Busbar trunking system complexity | More tap-off points, bends, or joints increase labor and material needs. | Complex trunking layout costs more than straight runs |

| Supplier location & logistics | Freight and import duties can significantly affect pricing. | Overseas shipping may add $500–$1,000 per container |

4.Typical Price Ranges for Busbar Products

While prices fluctuate with raw material markets, here’s a general busbar products price comparison for industrial buyers:

| Busbar Type | Estimated Price Range (USD per meter) | Notes |

| Copper busbar (bare) | $20 – $50 | Depends on cross-section and purity |

| Aluminum busbar (bare) | $8 – $25 | Lower cost, lighter weight |

| Insulated copper busbar | $30 – $65 | Added insulation for safety |

| Insulated aluminum busbar | $15 – $40 | Economical insulated option |

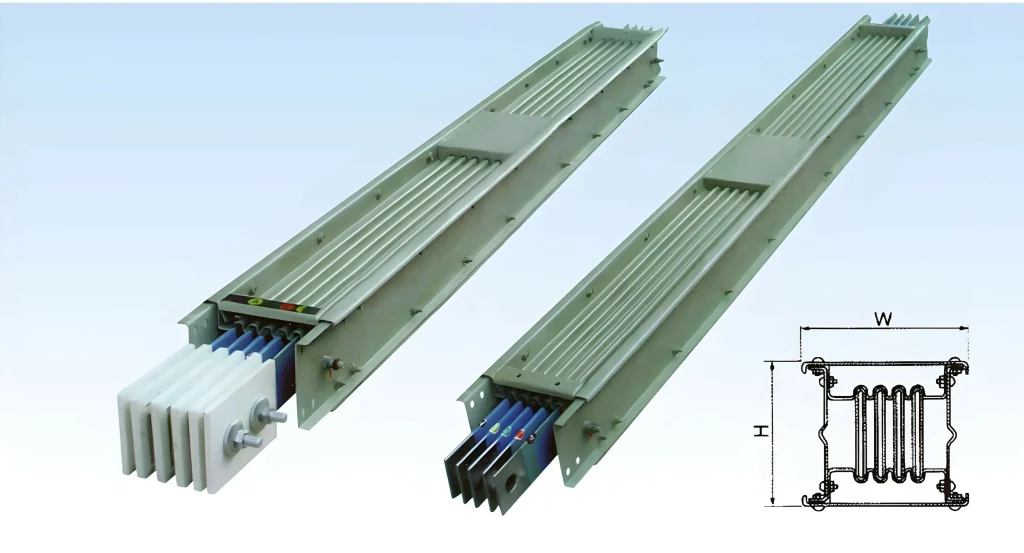

| Busbar trunking system | $45 – $120 | Includes trunking housing and joints |

| Custom busbar | Varies | Depends on bends, holes, plating, insulation |

Tip: Always request transparent pricing for busbar products and services to see material, labor, and logistics costs separately.

5.Are Custom Busbars More Expensive Than Standard Ones?

Yes—cost estimate for custom busbar manufacturing is usually higher due to:

1.Design and engineering labor

2.Special tooling for bending, punching, or plating

3.Lower economies of scale for unique designs

However, custom designs can reduce installation time and improve performance, leading to overall savings in complex electrical projects.

6.How to Get the Best Price for Busbar Products

1.Compare multiple suppliers – Use a busbar products price comparison for industrial buyers chart to benchmark offers.

2.Buy in bulk – Can bulk purchasing reduce busbar product costs? Absolutely—large orders spread setup costs.

3.Consider material alternatives – For lower load requirements, aluminum busbar may be a better value than copper.

4.Negotiate service packages – Some suppliers offer busbar trunking installation and maintenance contracts at a discount.

5.Request fixed quotes – Avoid exposure to raw material price fluctuations.

7.Value vs. Price: What to Consider

When buying busbars, how to evaluate value vs price means looking beyond the initial number:

Value drivers:

1.Compliance with IEC, UL, or GB standards

2.Longevity and corrosion resistance

3.After-sales support and warranty terms

4.Availability of custom busbar designs

A low-cost busbar that fails prematurely can lead to expensive downtime and replacements.

8.Cost-Saving Tips for Purchasing Busbar Products

1.Combine orders across projects to maximize bulk discounts.

2.Choose pre-drilled busbars to reduce labor costs on-site.

3.Work with local suppliers to cut shipping costs.

4.Plan ahead to avoid rush manufacturing fees.

9.Budgeting for Busbar Products in Electrical Projects

A good budgeting process includes:

1.Listing all busbar components required (straight sections, elbows, tap-offs, joints).

2.Separating material and installation costs.

3.Adding a 10–15% contingency for raw material price changes.

4.Consulting suppliers for price quotation for bulk busbar product orders early in the project.

10.FAQs – Busbar Products Pricing

1.How much do busbar products cost?

Depending on material, size, and insulation, prices range from $8/m to over $120/m.

2.Does busbar material impact the overall cost?

Yes—copper is more expensive but offers higher conductivity and durability.

3.How to budget for busbar products in electrical projects?

Plan early, request multiple quotes, and include contingency for market fluctuations.

4.Where to find affordable busbar products without sacrificing quality?

Partner with best value busbar products suppliers near you who offer quality assurance and transparent pricing.

11.Why Choose Welleshaft for Busbar Sourcing Support?

We work directly with busbar manufacturing partners to ensure:

Competitive, transparent pricing

Strict compliance with quality standards

Flexible order quantities

Support for both custom busbar and standard designs

Whether you need affordable busbar products with high quality or budget-friendly busbar solutions for electrical panels, we help you get the best price-to-performance ratio.

Written by a senior electrical systems engineer at Welle , with over 12 years of experience in busbar manufacturing, sourcing strategy, and cost optimization for industrial and commercial power distribution projects.