Premium Aluminum Sections: Aluminum Fasteners – Lightweight, Corrosion-Resistant Solutions Aluminum has revolutionized industries worldwide with its exceptional strength-to-weight ratio, corrosion resistance, and versatility. In the realm of construction, manufacturing, and even DIY projects, the use of premium aluminum sections paired with reliable aluminum fasteners is becoming increasingly prevalent. This article delves into the world of […]

Kategorie-Archive: Study cases and knowledge

Discover industriy trends, case studies, how-to guides, manufacturing processes and FAQs on Welleshaft’s Knowledge Hub—expert insights for engineers and sourcing professionals.

Welleshaft’s Study Cases and Knowledge page addresses key sourcing challenges, quality control hurdles, and real manufacturing pain points—helping buyers make smarter, faster decisions.

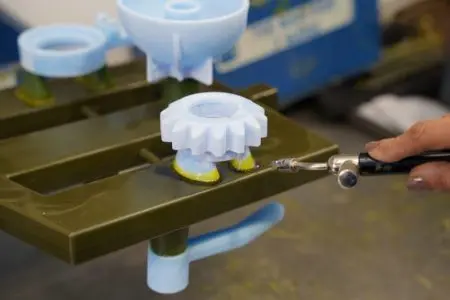

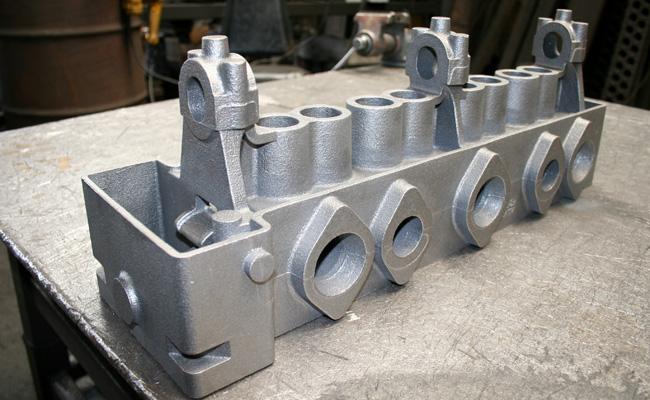

Quick Cast Prototyping Solutions: Precision Metal Parts, Quickly Section 1:Introduction In today’s fast-paced product development environment, speed and efficiency are paramount. Traditional prototyping methods can often be time-consuming and costly, hindering innovation and delaying time-to-market. Quick cast prototyping offers a revolutionary solution, enabling rapid production of precision metal parts with unmatched speed and accuracy. This […]

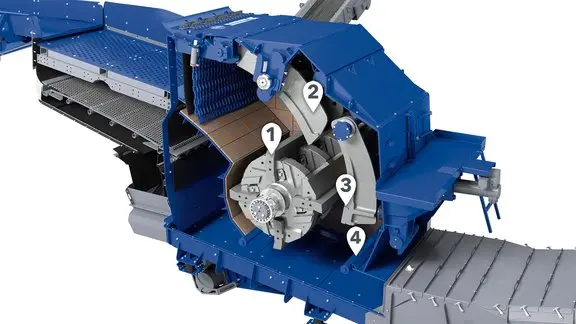

Grinding Mill Liners: Quality Liners for Optimal Grinding Performance Section 1:Introduction In the realm of industrial mineral processing, grinding mills play a pivotal role in reducing particle size to desired specifications. However, the efficiency and longevity of these mills heavily rely on the quality of their internal components, particularly the grinding mill liners. These liners, […]

Impacting Blow Bars: Durable Crusher Parts for Effective Size Reduction Section 1:Introduction In the realm of material processing, efficient size reduction is paramount. Impact crushers, with their powerful blows, play a crucial role in achieving this goal. At the heart of these machines lie impacting blow bars, the workhorses that deliver the crushing force. These […]

Section 1:Introduction In metal casting, innovation drives advancements in manufacturing processes. One such groundbreaking technology leverages additive manufacturing to create intricate and precise molds for superior castings. This article explores the advantages, applications, and the role of trusted global suppliers like Welleshaft in shaping the future of this transformative technology. Section 2:Understanding 3D Printed Sand […]

Introduction In the realm of medical technology, precision isn’t just a luxury; it’s a necessity. The efficacy of medical devices, from life-saving implants to delicate surgical instruments, hinges on the accuracy and reliability of their components. This is where medical CNC machining steps in, playing a pivotal role in bringing cutting-edge medical advancements to fruition. Among the […]

Durable Rubber Mill Liners | High-Performance Solutions for Mining & Milling Operations In the demanding industries of mining and milling, where durability and performance are critical, Durable Rubber Mill Liners have emerged as an indispensable solution. These liners deliver exceptional wear resistance, reduce operational downtime, and offer long-term cost-effectiveness—making them a superior alternative to traditional […]

China Rubber Liners for Rod Mill | High Wear-Resistant Composite Ceramic Liners | Practical Ball Mill Liners for Industry In industries such as mining, cement, chemical processing, and others that involve grinding and milling processes, the efficiency of the milling operation is highly dependent on the materials used in the mill itself. One of the […]

Advanced Rubber Mill Liner for Enhanced Efficiency | Durable & High-Performance Solutions In the world of heavy industries like mining, cement production, and other grinding applications, equipment efficiency and durability are paramount. One crucial component that plays a significant role in milling operations is the mill liner. It protects the mill’s inner surface, ensures optimal […]

Durable Rubber Ceramic Wear Liners | High-Performance Solutions for Mining & Industrial Applications Mining and industrial operations demand high-performance solutions that endure harsh environments and optimize efficiency. Rubber-ceramic composite liners have emerged as a revolutionary product offering unparalleled durability, superior wear resistance, and cost-effectiveness. Welleshaft, a global supplier and contract manufacturer, specializes in delivering premium-quality […]