The Ultimate Guide to Stainless Steel Fasteners: Types, Grades, and Applications

Customed Stainless Steel Fasteners play a critical role across industries—from construction and automotive to marine and medical devices. At Welleshaft, we know that selecting the right fastener isn’t just about choosing a material—it’s about ensuring long-term performance, safety, and reliability.

This complete guide covers everything you need to know about stainless steel fasteners: types, available steel grades, thread and head styles, selection tips, and the key standards that support safe, efficient use.

What Are Stainless Steel Fasteners?

Fasteners are hardware devices used to mechanically join or affix two or more objects together. Stainless steel fasteners are particularly valued for their exceptional corrosion resistance, durability, and low maintenance requirements.

Most commonly, stainless steel fasteners come in the form of:

- Bolts

- Screws

- Studs

- Nuts

- Washers

Each fastener generally comprises a head, shank, and threaded portion, although variations exist depending on the application.

What Are Bent Anchor Bolts?

Bent anchor bolts—commonly formed into L-shaped or J-shaped configurations—are used to anchor structures to concrete. These bolts are bent at a 90-degree angle at the embedded end, which helps provide resistance against forces that might otherwise pull the bolt out of the concrete. The exposed threaded section allows for secure attachment of structural components.

These anchors are essential in high-load structural projects and are widely used in sectors such as transportation, energy, telecommunications, and construction.

Stainless Steel Bent Anchor Bolt Specifications

Welleshaft can supply a wide range of custom and standard specifications, including:

- Sizes: M6 to M64, or 1/4″ to 2-1/2″

- Thread type: Metric, UNC, UNF, BSW

- Finish: Pickled, passivated, or polished

- Bend types: L-bend, J-bend, U-bend

- Lengths: From 50mm to 3000mm+

- Certifications: ISO 9001, CE, ROHS, DFARS-compliant

We also offer optional non-destructive testing (NDT), heat treatment certification, and dimensional inspection reports for high-precision applications.

Why Choose Stainless Steel Fasteners?

Stainless steel is prized for its combination of strength, resistance to rust and oxidation, and self-healing protective layer formed by chromium content. These benefits make stainless steel fasteners the ideal choice for:

- Outdoor applications

- High-humidity or saltwater environments

- Chemical processing plants

- Food-grade installations

Beside, Unlike carbon steel options, 304 and 316 stainless steel bent anchor bolts offer:

- Corrosion resistancein harsh and wet environments

- Superior strength and durability

- Low maintenance over time

- Suitability for coastal, marine, and chemical exposure

- Extended service lifeeven in high-stress applications

304 vs 316 Stainless Steel Bent Anchor Bolts

| Feature | 304 SS | 316 SS |

| Chromium (%) | 18–20% | 16–18% |

| Nickel (%) | 8–12% | 10–14% |

| Molybdenum (%) | 0% | 2–3% |

| Corrosion Resistance | Excellent | Superior (especially in saltwater & chemicals) |

| Common Use | Industrial, commercial | Marine, pharmaceutical, chemical plants |

| Cost | Lower | Higher, but more durable in harsh environments |

Stainless steel fasteners are especially ideal for projects where long-term integrity, appearance, and safety are critical.

Common Types of Stainless Steel Fasteners

Stainless steel fasteners are available in many forms to suit a wide range of applications. The most widely used grades are 304 (general-purpose) and 316 (marine-grade), offering excellent corrosion resistance, strength, and durability.

1. Stainless Steel Bolts

- Hex Bolts (Hex Cap Screws): Standard bolts with a six-sided head, commonly used in structural and machinery applications.

- Carriage Bolts: Round head bolts with a square neck that keeps them from spinning once inserted.

- Anchor Bolts: Embedded in concrete; includes bent anchor bolts(L- or J-bent).

- Shoulder Bolts: Used in applications with rotating components, like pulleys or gears.

2. Stainless Steel Nuts

- Hex Nuts: Standard six-sided nuts.

- Nylon Insert Lock Nuts: Contain a nylon collar that resists loosening from vibration.

- Flange Nuts: Have a built-in washer-like flange for load distribution.

- Cap Nuts (Acorn Nuts): Domed to cover exposed bolt threads for aesthetics and safety.

3. Stainless Steel Screws

- Machine Screws: Used with pre-threaded holes or nuts in machinery and electronics.

- Self-Tapping Screws: Create their own thread in softer materials like plastic or wood.

- Wood Screws: Designed specifically for wood fastening.

- Deck Screws: Coated and corrosion-resistant, ideal for outdoor construction.

- Sheet Metal Screws: Used to fasten thin metal sheets together.

4. Stainless Steel Washers

- Flat Washers: Distribute load and protect surfaces.

- Spring Washers: Provide tension to prevent loosening.

- Lock Washers: Prevent fasteners from loosening due to vibration.

5. Stainless Steel Rivets

- Used for permanent fasteningof materials like sheet metal or plastics.

- Common in automotive, aircraft, and appliance

6. Stainless Steel Threaded Rods

- Fully threaded along their length.

- Ideal for tensioning, supporting beams, and pipe installations.

- Often used in construction, HVAC, and electrical systems.

7. Stainless Steel Pins

- Includes dowel pins, cotter pins, clevis pins, and hitch pins.

- Used for alignment, locking components, or pivoting.

Each type serves specific functions across industrial, mechanical, and structural applications.

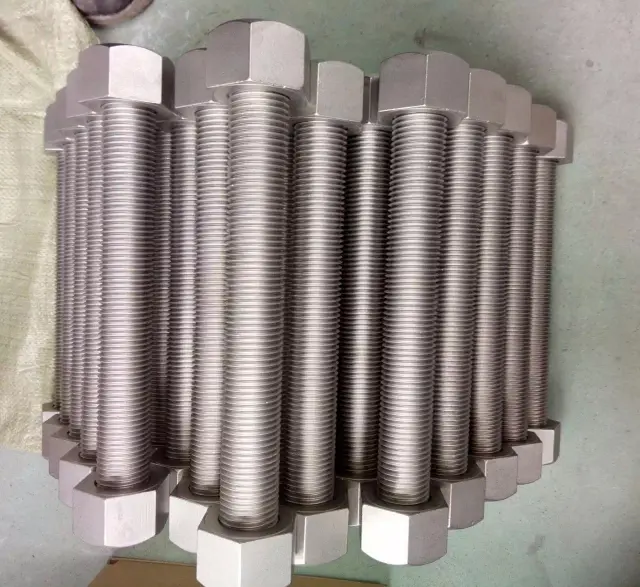

8. Hex Head Bolts

Hex bolts, also referred to as hex screws or hexagonal head bolts, are among the most common fasteners used worldwide. Options include:

- Hex Bolt, Stainless Steel, Fully-Threaded

- Stainless Steel 316L( A4/70)Hex Bolt (Full Thread)

- DIN-933 A2 – Hexagonal head bolt 8.8, Full Thread

- Hex Bolts Full Thread 304 Stainless Steel

These are ideal for both structural and mechanical applications.

9. L Shaped Stainless Steel Bolts

Often referred to as L Bolts or L-Shaped Anchor Bolts, these bolts are used to secure structural elements to concrete foundations. Applications include:

- M8x80mmor M8x 800mm L Shape Foundation Bolts

- Stainless Steel L Shaped Bolt | A36

- L Shaped Stainless Steel Bolts Sizes

L-shaped bolts are also known for their use in pre-cast concrete, signage, and industrial frameworks.

10. Extra Long Stainless Steel Bolts

Extra long stainless steel bolts are essential in applications requiring deep embedding or clamping. Common variations include:

- Stainless Steel Hex Head Extra Long Screw/Bolt

- EXTRA Long Stainless Steel Bolt & Locking Ring

- Stainless Steel Extra Large Flanged Hex Bolts Screws

Stainless Steel Grades for Fasteners

Not all stainless steel fasteners are created equal. Different grades offer varied performance depending on environmental exposure, mechanical stress, and compatibility.

Grade A2/304 Stainless Steel

- Most widely used

- Excellent corrosion resistance for general industrial and household applications

- Common in handrails, kitchen equipment, automotive parts, and piping systems,Indoor and dry outdoor environments, food processing, general construction

- 304 Stainless Steel Bent Anchor Bolts

Grade A4/316 Stainless Steel

- Contains molybdenumfor superior corrosion resistance

- Ideal for marine, offshore, chemical processing, and chloride-heavyenvironments, outdoor infrastructure near the coast

- Slightly more expensive than 304, but necessary for salt sprayor acidic conditions

- 316 Stainless Steel Bent Anchor Bolts

400 Series (Grades 410 and 420)

- Martensitic stainless steel, heat-treatable for hardness

- Offers magnetic propertiesand higher strength

- More brittle and harder to cold-form than austenitic grades

- Suitable for cutting tools, wear-resistant parts, and non-corrosive indoor environments

Specialty Alloys

- Duplex and super austenitic alloys are also available for extreme applications

- Consider these for high-pressure reactors, desalinization plants, and aerospace uses

Manufacturing Process of Stainless Steel Bolts

1. Raw Material Selection

- Material: Stainless steel wire rods (usually Grade 304 or 316).

- Diameter and length are selected based on bolt specifications.

2. Cold/Hot Forging (Head Formation)

- Cold forgingfor smaller bolts (up to M24): Wire is cut and formed at room temperature.

- Hot forgingfor larger bolts: Material is heated and then shaped in dies.

- Bolt head (hex, square, etc.) is formed using upsetting dies.

3. Thread Rolling or Cutting

- Thread Rolling(preferred): Threads are formed by rolling between dies—stronger due to grain flow.

- Thread Cutting: Used for larger diameters or custom threads.

4. Heat Treatment (Optional)

- Some stainless bolts may undergo solution annealingor hardening to enhance mechanical properties.

5. Surface Finishing

Options include:

- Passivation: Removes free iron and enhances corrosion resistance.

- Polishing: For improved aesthetics and cleanliness.

- Coating (if applicable): PTFE, black oxide, etc., for special environments.

6. Inspection & Quality Control

- Dimensional checks, tensile tests, hardness tests, and visual inspection.

- Certifications: EN 10204 3.1, ISO, ASTM A193/A320 (if applicable).

Manufacturing Process of Stainless Steel Bent Anchor Bolts

1. Cutting Raw Rods

- Stainless steel rods or rebar are cut to the required length.

2. Threading

- One or both ends are threaded using rollingor cutting, depending on size and spec.

3. Bending

Bending into “L”, “J”, or custom shapes using:

- Manual hydraulic bending machines

- CNC rod bending machinesfor large-volume jobs.

4. Heat Treatment (if needed)

- Used for stress relief or specific mechanical property enhancement.

5. Surface Treatment

- Passivationor pickling to improve corrosion resistance, especially for 316 bolts used in marine/concrete environments.

6. Marking & Inspection

- Marked with heat numbers, batch codes, or project codes.( such as. Laser Marking)

- Checked for bend angle, thread length, straightness, and tensile strength.

Measuring Methods

For Stainless Steel Bolts:

| Parameter | Measuring Tool | Notes |

| Overall length | Vernier caliper, ruler | From under head to tip |

| Thread pitch | Thread gauge | Matches ISO/UNC/UNF |

| Thread length | Caliper | Measured from thread start to end |

| Shank diameter | Micrometer or caliper | Tolerance check (e.g., ISO 4014) |

| Head dimensions | Micrometer, caliper | Width across flats (WAF) & thickness |

| Hardness | Rockwell or Vickers tester | Material property check |

| Tensile strength | Universal Testing Machine (UTM) | For batch testing |

For Stainless Steel Bent Anchor Bolts:

| Parameter | Measuring Tool | Notes |

| Total length | Steel scale, caliper | From top to end of bend |

| Bend radius & angle | Protractor, custom jig | Ensures accurate “L” or “J” shape |

| Threaded length | Caliper | Check thread standard compliance |

| Straightness | Visual or straight edge | Especially important for embedment |

| Diameter | Caliper or micrometer | Nominal and actual diameter |

| Coating thickness | Coating thickness gauge | If coated or galvanized |

| Mechanical strength | Tensile/bend test rigs | Project-based compliance testing |

Head Types: Function and Torque Capacity

The shape of a fastener’s head affects its torque resistance, tool compatibility, and aesthetic finish.

| Head Type | Common Uses | Advantages |

| Hex Head | Flanges, Structural Assemblies | High torque, strong grip |

| Socket Head | Machinery, Compact Spaces | Flush fit, neat finish |

| Button Head | Light-duty connections | Smooth, rounded surface |

| Flat Head | Countersunk applications | Flush with surface |

| Pan/Round Head | Electrical, enclosures | Simple, accessible |

The driving recess (e.g., Phillips, Torx, Slotted, Allen) should also be selected based on required torque and available tools.

Thread Types: Coarse, Fine, and Specialized Threads

Thread design is crucial for load distribution and vibration resistance.

- Coarse Threads

- Faster assembly

- Greater resistance to thread galling

- Better for soft materials

- Fine Threads

- Stronger in tension

- Better for precision instruments

- Less resistant to stripping in soft materials

- 8-Thread Series

- Common in 1-inch or largerbolts

- Used for high-stress industrial applications

End Point Design: Flat, Self-Tapping, and Self-Drilling

Fasteners may come with different end designs:

- Flat Ends: Standard, requires a pre-drilled hole

- Self-Tapping: Cuts its own threads in softer materials like plastic or aluminum

- Self-Drilling: Combines drilling and tapping in one operation, reducing installation time

Your application’s material hardness and installation environment will dictate which end design is most effective.

Standards for Stainless Steel Fasteners

To ensure safety, compliance, and performance, stainless steel fasteners should meet internationally recognized standards:

| Standard | Description |

| ASTM A193/A193M | High-temp or high-pressure bolting |

| ASTM A307 | Carbon steel bolts, studs, threaded rod |

| ASTM A320 | Low-temperature applications |

| ASTM F593 | SS bolts, studs, cap screws |

| ASTM F594 | SS nuts |

| ASME B1.1 | Unified inch screw threads |

| ASME B18.2.2 | Nuts for general applications |

Welleshaft ensures our fasteners meet or exceed these benchmarks.

Common Applications of Stainless Steel Fasteners

The superior characteristics of stainless steel fasteners make them ideal across various industries and harsh environments. Welleshaft’s stainless steel bolts, screws, nuts, and custom anchors are used in:

• Marine & Offshore Structures

Where exposure to saltwater spray and high humidity is constant, 316 stainless steel provides superior protection.

• Infrastructure & Civil Engineering

Used in bridges, tunnels, foundations, and retaining structures requiring long-term strength and corrosion resistance.

• Transportation & Rail

SS fasteners are used for rail systems, highway guardrails, and transportation infrastructure exposed to road salts and vibration.

• Chemical Processing Plants

316 stainless steel fasteners resist acidic and alkaline media, offering safety and longevity in tanks, piping, and valves.

• Food & Pharmaceutical Industries

Where hygiene is critical, 304 and 316 fasteners are chosen for their non-reactive, easy-to-clean properties.

• Renewable Energy Installations

Solar and wind systems often require fasteners that withstand UV, temperature cycling, and coastal exposure.

Common Applications of SS Bent Anchor Bolts

Stainless steel bent anchor bolts are fundamental components in concrete-embedded systems where tension and shear resistance are vital. Their bent design provides anchoring leverage, reducing pull-out risk in high-load conditions.

Used in:

- Light Poles & Traffic Signals– Urban infrastructure exposed to rain, road salt, and mechanical vibrations.

- Bridges & Overpasses– High-load anchoring of columns, supports, and base plates.

- Industrial Machinery Foundations– Securing heavy equipment subject to vibration and dynamic loading.

- Signage & Towers– Ensuring stability against wind loads and shifting soil.

- Architectural Steel Columns– Embedded base anchoring of vertical steel structures.

- Marine & Coastal Construction– Ideal for dock structures, breakwaters, and offshore platforms.

Common Questions Answered

- What is a fully threaded bolt called?

It’s typically referred to as a “full thread hex bolt” or “fully-threaded bolt.” See: Hex Bolts Full Thread 304 Stainless Steel. - Are fully threaded bolts weaker?

Not necessarily; rolling threads can enhance tensile strength. However, shank bolts may resist shear better. - Can you get high tensile stainless steel bolts?

Yes, especially in 316 or alloyed types certified to ASTM A193 standards. - What are the disadvantages of stainless steel bolts?

Higher cost, potential galling under high torque, and sometimes lower strength than carbon steel equivalents.

Get a Custom Quote for Stainless Steel Fasteners

Looking for bulk stainless steel fastener solutions or SS bent anchor bolts for your next project? Let Welleshaft be your reliable global partner. Our production capabilities support projects across civil engineering, oil & gas, transportation, marine construction, and more.

Contact our team today or submit a quick quote request to get competitive pricing on custom stainless steel fasteners.