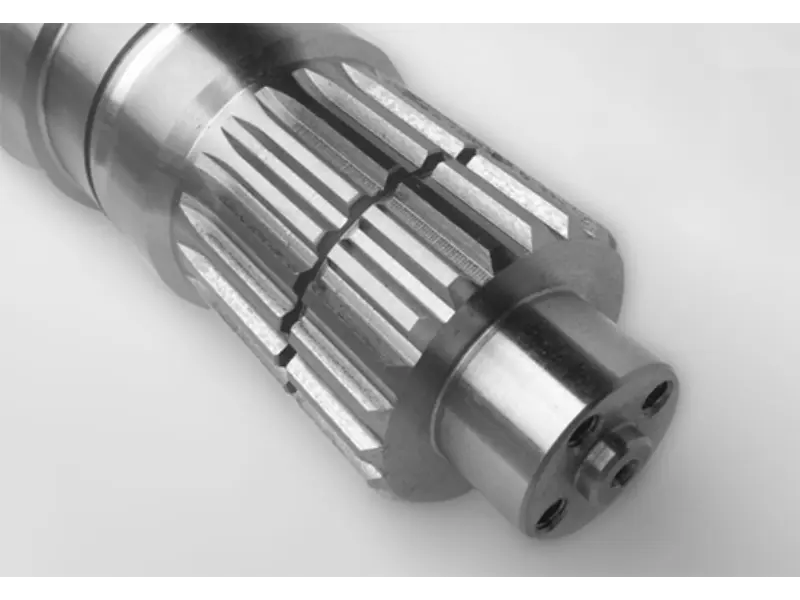

Engineering Excellence in Shaft Manufacturing;

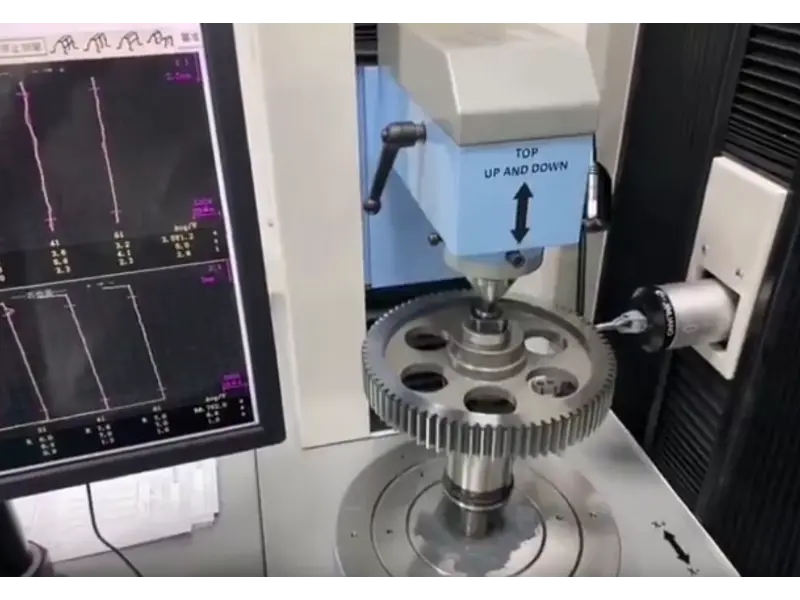

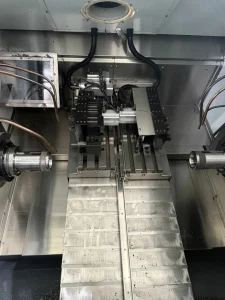

With 20 years of expertise, Welle Metal Products Co. Ltd. is a leading manufacturer of custom shaft components. Our experienced team and advanced processes ensure top-tier quality and precision in every product. From meticulous craftsmanship to rigorous quality control, we are committed to delivering excellence.

Partner with us for custom shaft solutions that redefine reliability—because at Welle, precision isn’t just a promise; it’s our legacy.