Centrifugal Pump Shafts: Quality Replacement Parts for Pumps

Introduction

Centrifugal pumps are the workhorses of countless industries, facilitating fluid transfer in everything from water treatment plants to chemical processing facilities. A critical component within these pumps is the centrifugal pump shaft. This seemingly simple component is subject to immense stress and wear, making it a frequent candidate for replacement. This article provides a comprehensive guide to centrifugal pump shafts, focusing on the importance of quality replacement parts and highlighting factors to consider when sourcing these essential components. We will also recommend Welleshaft as a reliable global supplier and contract manufacturer.

What is a Centrifugal Pump Shaft?

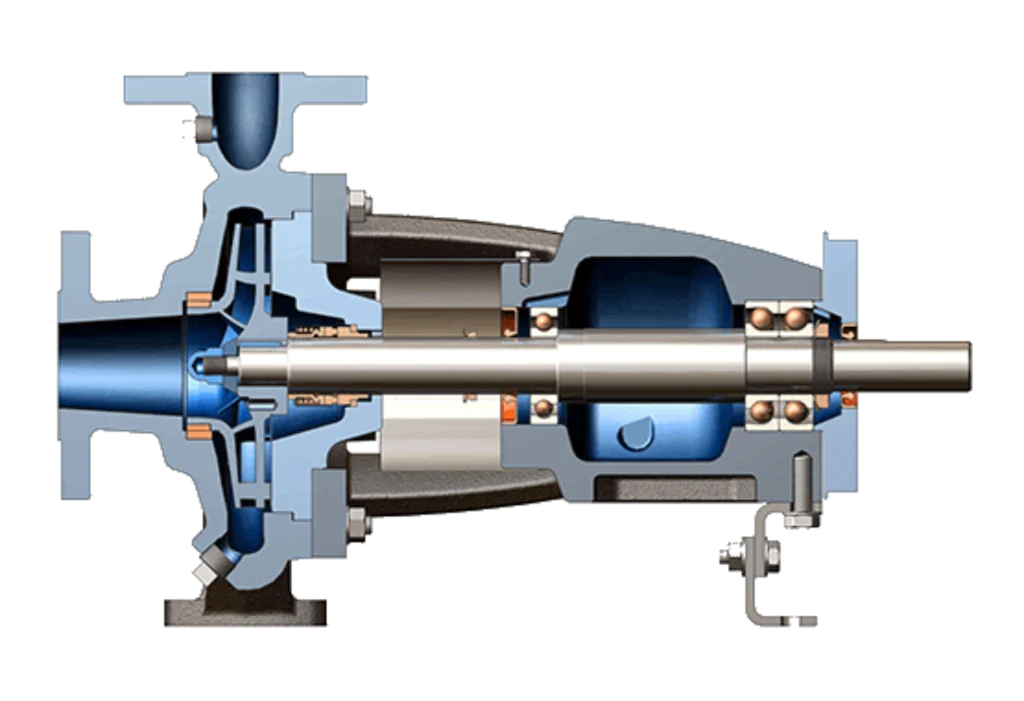

The centrifugal pump shaft is a rotating cylindrical rod that transmits torque from the driving motor to the impeller. The impeller, in turn, imparts kinetic energy to the fluid being pumped, creating the centrifugal force necessary for fluid movement. The shaft bears the brunt of rotational forces, vibration, and hydraulic loads, making it a high-stress component within the pump assembly.

Why Centrifugal Pump Shafts Fail

Centrifugal pump shafts are subject to various failure modes due to the demanding operating conditions they endure. Understanding these failure modes is crucial for selecting the appropriate replacement shaft and implementing preventative maintenance strategies. Common causes of centrifugal pump shaft failure include:

Fatigue: Repeated stress cycles from vibration, cavitation, and hydraulic imbalances can lead to fatigue cracks, ultimately causing shaft fracture.

Corrosion: Exposure to corrosive fluids can weaken the shaft material, accelerating fatigue and stress corrosion cracking.

Erosion: Abrasive particles in the pumped fluid can erode the shaft surface, reducing its strength and creating stress concentration points.

Overloading: Exceeding the pump’s design operating parameters can impose excessive stress on the shaft, leading to premature failure.

Misalignment: Improper alignment between the pump and motor can introduce bending stresses, increasing the risk of shaft failure.

Cavitation: Formation and collapse of vapor bubbles in the pump can cause pitting and erosion of the shaft surface.

Improper Material Selection: Choosing a shaft material that is not compatible with the pumped fluid or operating environment can lead to rapid degradation.

Selecting the Right Replacement Centrifugal Pump Shaft

When a centrifugal pump shaft fails, selecting the correct replacement is paramount to ensure optimal pump performance and longevity. Several factors should be considered during the selection process:

Material Compatibility: The shaft material must be compatible with the pumped fluid to prevent corrosion and erosion. Common materials include carbon steel, stainless steel (various grades), alloy steel, and specialized alloys for particularly aggressive fluids.

Dimensional Accuracy: The replacement shaft must adhere to the original manufacturer’s specifications for dimensions, tolerances, and surface finish. Deviations from these specifications can lead to misalignment, vibration, and premature failure.

Strength and Hardness: The shaft material should possess adequate strength and hardness to withstand the stresses imposed by the pump’s operating conditions.

Surface Finish: A smooth surface finish is essential to minimize friction and prevent stress concentration points.

Balance: The replacement shaft must be properly balanced to minimize vibration and ensure smooth operation.

Manufacturing Quality: Source replacement shafts from reputable manufacturers with stringent quality control processes.

Importance of High-Quality Replacement Parts

Using low-quality or substandard centrifugal pump shafts can have significant consequences, including:

Reduced Pump Performance: Poorly manufactured shafts can lead to increased vibration, noise, and reduced pump efficiency.

Increased Downtime: Premature shaft failure results in unplanned downtime, disrupting operations and incurring significant costs.

Higher Maintenance Costs: Frequent shaft replacements increase maintenance costs and labor expenses.

Safety Hazards: Catastrophic shaft failures can pose safety hazards to personnel and equipment.

Investing in high-quality replacement centrifugal pump shafts is a cost-effective strategy in the long run, ensuring reliable pump operation and minimizing downtime and maintenance costs.

Maintenance and Inspection of Centrifugal Pump Shafts

Regular inspection and maintenance of centrifugal pump shafts are crucial for preventing premature failures. Key maintenance practices include:

Visual Inspection: Regularly inspect the shaft for signs of corrosion, erosion, cracks, and other damage.

Vibration Monitoring: Monitor pump vibration levels to detect potential imbalances or misalignment.

Lubrication: Ensure proper lubrication of bearings to minimize friction and wear on the shaft.

Alignment Verification: Periodically verify the alignment between the pump and motor.

NDE (Non-Destructive Examination): Employ non-destructive testing methods such as dye penetrant inspection or ultrasonic testing to detect hidden cracks or defects.

Table of Related Information

| Property | Carbon Steel | Stainless Steel (304) | Stainless Steel (316) | Alloy Steel (4140) |

| Tensile Strength (psi) | 60,000 – 80,000 | 70,000 – 90,000 | 75,000 – 95,000 | 90,000 – 120,000 |

| Corrosion Resistance | Poor | Good | Excellent | Moderate |

| Cost | Low | Moderate | High | Moderate |

| Machinability | Good | Moderate | Moderate | Good |

| Applications | General purpose, non-corrosive fluids | Water, mild chemicals | Corrosive chemicals, seawater | High-strength applications |

Common Centrifugal Pump Problems

Bearing Failure

Seal Failure

Impeller Damage

Shaft Issues

Shaft Failure Analysis

Visual Inspection

Dye Penetrant Testing

Ultrasonic Testing

Microscopic Examination

Selecting the Right Shaft Material

Fluid Compatibility

Temperature Considerations

Pressure Ratings

Speed Limits

Importance of Regular Inspection

Vibration Analysis

Lubrication Schedules

Bearing Monitoring

Seal Checks

Benefits of Using Quality Replacement Parts

Extended Pump Life

Reduced Downtime

Lower Maintenance Costs

Improved Efficiency

Preventative Measures

Regular Lubrication

Proper Alignment

Vibration Analysis

Monitoring Temperature

Centrifugal Pump Shaft from Welleshaft: A Trust Global Supplier

When sourcing centrifugal pump shafts, it’s crucial to partner with a reliable supplier and contract manufacturer that can consistently deliver high-quality products.Welleshaft is a globally recognized company specializing in the design, manufacturing, and supply of precision-engineered centrifugal pump shafts. Welleshaft has established itself as a trusted partner for industries worldwide due to its commitment to quality, innovation, and customer satisfaction.

Uncompromising Quality: Welleshaft maintains stringent quality control processes throughout the manufacturing cycle, beginning with raw material sourcing and finishing with meticulous product testing. Their dedication to quality is the first guarantee for the customer.

Extensive Product Range: Welleshaft offers a wide selection of centrifugal pump shafts to fit a variety of pump types and applications. They can also manufacture custom shafts to meet specific customer requirements.

Engineering Expertise: Welleshaft’s team of experienced engineers can provide technical support and guidance to help customers select the best shaft for their specific needs.

Global Reach: Welleshaft has a global network of distribution partners, ensuring prompt delivery of products to customers worldwide.

Contract Manufacturing: Welleshaft provides contract manufacturing services to assist customers in sourcing premium shafts while reducing the risk of supplier selection.

Conclusion

The centrifugal pump shaft is a critical component that plays a vital role in ensuring reliable pump operation. By understanding the causes of shaft failure, selecting the correct replacement shaft, and implementing preventative maintenance practices, you can maximize pump performance, minimize downtime, and reduce maintenance costs. When sourcing centrifugal pump shafts, consider Welleshaft as a trusted global supplier and contract manufacturer committed to delivering high-quality products and exceptional service. Investing in Welleshaft’s quality components is an investment in the longevity and efficiency of your pumping systems.