1.A Comprehensive Guide to Metal Casting Inspection Methods & Quality Standards

The reliability of a precision investment cast component hinges on one critical factor: a meticulous and deeply ingrained culture of quality. For any high-performance part, from aerospace castings to medical implants, the verification process is not an afterthought—it is the foundation of performance, safety, and longevity. When we combine rigorous and comprehensive metal casting inspection methods with industry-leading casting quality standards, we enhance part integrity and ensure client satisfaction.

At Welleshaft, we are a leading manufacturer of investment castings, and we have built our reputation on a world-class methodology for casting quality control. This guide explores the essential inspection processes that ensure every component we produce, whether from stainless steel, aluminum alloy, or complex nickel based alloys, meets the most demanding specifications.

2.The Foundation of Quality: An Integrad Approach to the Investment Casting Process

We don’t achieve true casting quality at a final inspection checkpoint. We engineer it into every stage of the investment casting process, from initial design review to final shipment. At Welleshaft, we ensure that quality control is an active, continuous feedback loop.

We start by understanding the application, whether it’s for automotive investment casting services or critical defense castings. We collaborate with clients to optimize part design for manufacturability, ensuring the investment casting mold and subsequent casting tooling are perfected before the first pour. This proactive strategy minimizes potential issues and is a cornerstone of the benefits of investment casting.

3.Welleshaft’s Four-Pillar Framework for Metal Casting Inspection

To guarantee that every investment cast part meets our high standards, we employ a multi-faceted inspection framework. This framework is designed to verify the three core pillars of a quality casting: chemical integrity, dimensional accuracy, and structural soundness.

1. Chemical Composition Analysis & Verification

The performance of a cast component begins with its elemental DNA. The precise chemical composition of an alloy determines its strength, corrosion resistance, and behavior under stress. As a premier investment casting foundry, we treat chemical verification with the utmost seriousness.

-

Pre-Pour Spectrometry Testing

Befor any molten metal is poured, our metallurgy lab uses an advanced X-ray fluorescence (XRF) spectrometer to analyze a sample coupon. This test confirms that the alloy melt—whether it’s 300 series stainless steel, A356 aluminum for casting, or a specialized nickel alloy casting—is within the exact required specification. If any deviation is detected, minor alloying elements are added to perfect the heat. Another coupon is then tested and certified to ensure the chemical composition adheres strictly to standards like ASTM, AMS, and SAE.

-

Material Certification and Traceability

We test, certify, and record the chemical composition of every single alloy melt in our secure database, where we store records indefinitely. This creates a complete and auditable history for every part, a non-negotiable requirement for sectors like aerospace casting and defense-grade stainless steel applications.

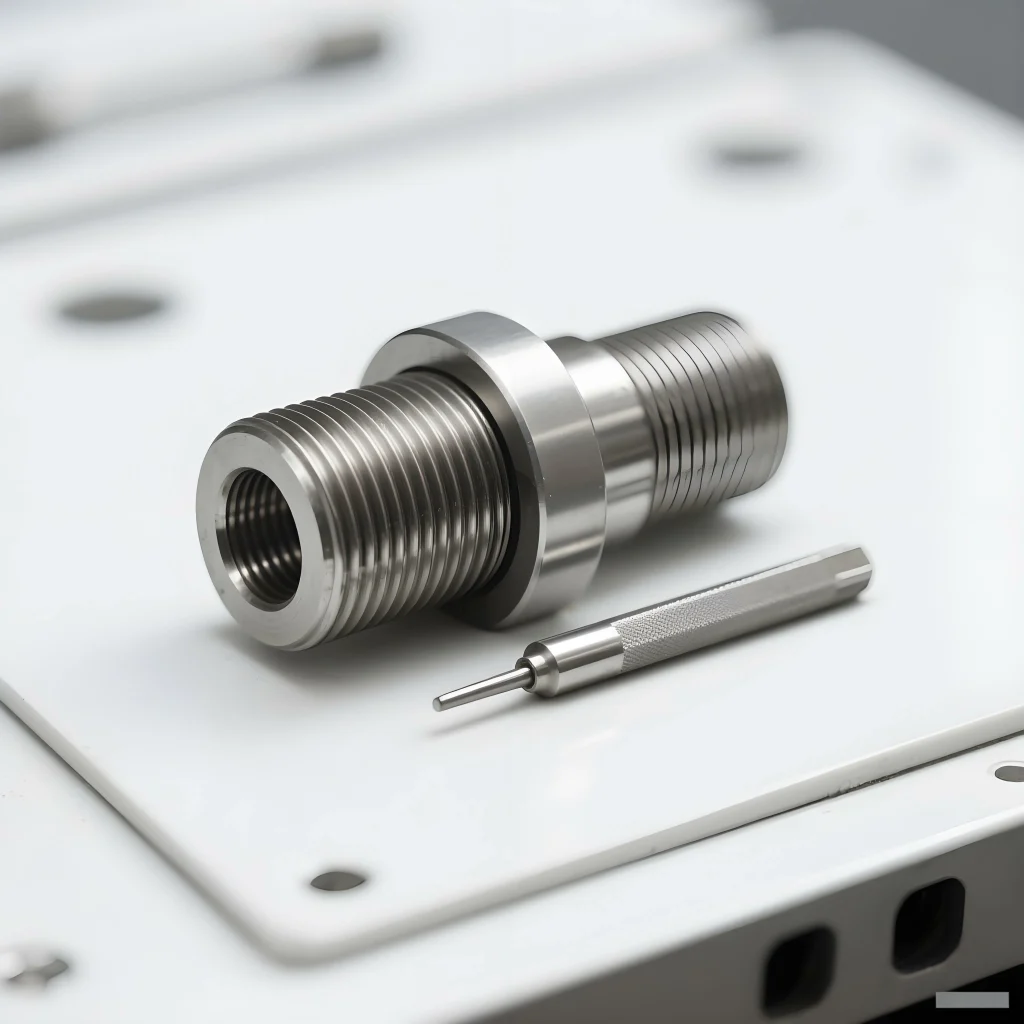

2. Dimensional Integrity Inspection

Precision metal casting is defined by its ability to produce complex, near-net-shape parts with tight tolerances. We verify that we deliver this promise with consistency and accuracy through our dimensional inspection process.

-

Advanced Measurement and Verification

Our quality experts utilize a suite of calibrated tools to verify every critical dimension. This includes:

- Coordinate Measuring Machines (CMM): For complex 3D geometries and airfoil castings.

- Micrometers & Calipers: For standard dimensional checks.

- Thread and Plug Gauges:To verify the accuracy of threaded features.

- Custom Functional Gauges:Designed to check specific, critical features as defined by the customer’s aplication.

We use Investment Casting Institute standards as a baseline and work closely with clients to identify the most critical part dimensions during the planning and casting quality inspection phases. This ensures that the parts function perfectly within their final assembly.

3. Mechanical Properties Testing

A part can have the perfect chemistry and dimensions, but it must also possess the required mechanical strength to perform its function. We conduct a series of tests to confirm the physical properties of the cast metal parts.

-

Hardness Testing (e.g., Rockwell, Brinell)

“We use this largely non-destructive procedure to gather crucial data on an alloy’s machinability and wear resistance. It serves as a key test for parts made from martensitic steel like 420 SS or 440C knife steel, where we prioritize surface hardness as a primary performance characteristic.

-

Tensile Testing

As a destructive casting quality test, tensile testing provides definitive data on a material’s structural limits. A test specimen is pulled until it fails, providing ultimate tensile strength, yield strength, elongation, and reduction of area values. This data is essential for verifying the properties of materials like ductile iron castings and alloy steel investment castings used in high-stress environments.

-

Load & Pressure Testing

For components that must bear a specific structural load, such as construction machinery investment cast components or parts for recreational vehicles, we perform load testing. This test verifies that the cast steel parts can carry the required load without failure or unacceptable deflection. For pressure-containing parts like a valve casting or pump components, we can perform hydrostatic testing to a proof load or its maximum limit.

4. Visual & Surface Inspection

Our trained experts conduct a meticulous visual inspection as the first line of defense in casting quality control. They use this process to identify surface-level imperfections that could indicate underlying issues.

Our specialists inspect each part carefully to ensure it is properly filled with metal and free from surface discontinuities like:

- Cracking or tearing

- Holes, voids, or porosity

- Non-fill or misruns

- Distortions or bends

During the final inspection phase, we compare parts against the casting quality control plan and written process instructions. We document the results, providing valuable feedback to our process engineers and production staff to continuously improve the investment casting procedure.

4.Advanced Non-Destructive Testing (NDT) for Critical Applications

For the most demanding applications where internal integrity is paramount, Welleshaft offers a full suite of in-house Non-Destructive Testing (NDT) services. NDT allows us to verify the internal soundness of a casting without damaging it, a critical requirement for industries like military & defense, automotive, and aerospace investment casting.

Our NDT inspection services are NADCAP Certified and include:

1.Dye (Liquid) Penetrant Testing (LPI)

This method is highly effective at detecting surface-breaking defects that are too small for the naked eye. We apply a fluorescent dye to the part, which seeps into any cracks. After cleaning, we apply a developer that draws the dye out, making even the tiniest flaws visible under UV light. This is a common test for non-ferrous metal casting capabilities, such as aluminium investment casting.

2.Magnetic Particle Inspection (MPI)

We use MPI to detect surface and near-surface discontinuities in ferromagnetic materials, including carbon steel casting and martensitic stainless steel. We magnetize the part and apply fine iron particles. The particles are attracted to any flux leakage fields caused by flaws, creating a visible indication of the defect.

3.Radiographic Testing (RT) / X-Ray Inspection

Radiography is the ultimate tool for verifying internal casting quality. By passing X-rays through a component, we can create an image of its internal structure, revealing hidden defects such as:

- Internal porosity or gas voids

- Shrinkage

- Inclusions

- Internal cracks

This level of aerospace non destructive testing is essential for ensuring the safety and reliability of flight-critical airfoil castings and other key components.

5.Choosing the Right Inspection Method

The selection of an inspection method depends on the alloy, part complexity, and the criticality of the application. The table below provides a general guide.

| Inspection Method | What It Detects | Destructive? | Common Materials | Typical Application |

| Chemical Spectrometry | Elemental alloy composition | No (coupon is tested) | All metals (stainless steel, aluminum, nickel alloys) | Foundation of all quality casting; material verification. |

| Visual Inspection | Surface flaws, non-fill, distortion | No | All castings | Standard initial quality check for all parts. |

| Dimensional (CMM) | Geometric accuracy, complex profiles | No | All castings | Precision casting for aerospace, medical, defense. |

| Hardness Testing | Wear resistance, machinability | Largely No | Steel alloys, hardened metals | Verifying heat treatment; parts like 440c ss. |

| Tensile Testing | Strength, ductility, yield point | Yes | Structural alloys (ductile iron, steel) | Validating material properties for load-bearing parts. |

| Liquid Penetrant (LPI) | Surface-breaking cracks | No | Non-ferrous (e.g., A356 aluminum) | Finding micro-cracks on aluminum alloy castings. |

| Magnetic Particle (MPI) | Surface/near-surface cracks | No | Ferromagnetic (e.g., 4130 alloy steel) | Inspecting steel castings and iron castings. |

| Radiography (X-Ray) | Internal voids, shrinkage, inclusions | No | All materials | Critical aerospace casting and defense castings. |

6.People Also Ask

-

What is the difference between investment casting and sand casting?

The main difference lies in the mold material and resulting precision. Investment casting vs sand casting shows that investment casting uses a ceramic shell created around a wax pattern, allowing for much finer detail, We achieve smoother surface finishes and tighter tolerances in investment casting, making it ideal for complex precision metal casting. In sand casting, we use a sand mold, which suits larger, less intricate parts better.

-

What materials are used in the investment casting process?

The investment casting process is incredibly versatile. We routinely work with a vast range of casting alloys, including 300 series stainless steel (austenitic) and 400 series stainless (martensitic), aluminum casting alloys like A356, alloy steel investment castings, brass investment casting, copper castings, and high-performance cast nickel alloys.

-

How does Welleshaft ensure quality for aerospace or defense castings?

We combine our standard rigorous inspection with industry-specific requirements. This includes NADCAP certified aerospace NDT services, complete material traceability, adherence to AMS specifications (e.g., AMS 5837), and a quality management system certified to AS9100 standards.

-

What is the difference between austenitic and martensitic stainless steel?

Austenitic stainless steel (like the 300 series stainless) has a specific crystal structure, is non-magnetic, and offers excellent corrosion resistance and formability. We heat-treat martensitic stainless steel (like 410 stainless steel or 420 SS) to achieve very high hardness and strength, making it ideal for applications requiring wear resistance, but it remains magnetic.

7.Quality Metal Castings by Welleshaft

Welleshaft is more than an investment casting manufacturer; We act as your strategic partner in producing high-performance, reliable components. From custom investment cast parts to high-volume production runs, we remain committed to quality. We examine, inspect, and approve every investment cast part we ship to ensure it meets the highest industry standards.

Contact us today to learn more about our metal casting inspection methods or to request a quote for your project. Let us show you how our proven casting quality can elevate your products.