When working in environments where sparks pose significant safety risks, choosing the right materials becomes critical. The Brass ACME Threaded Rod offers an ideal solution for such conditions, thanks to its non-sparking properties and excellent durability. In this article, we’ll explore the key benefits of the Brass ACME Threaded Rod, its common applications in hazardous environments, and why Welleshaft stands out as the premier global supplier of these essential components.

Can you explain what an ACME threaded rod is?

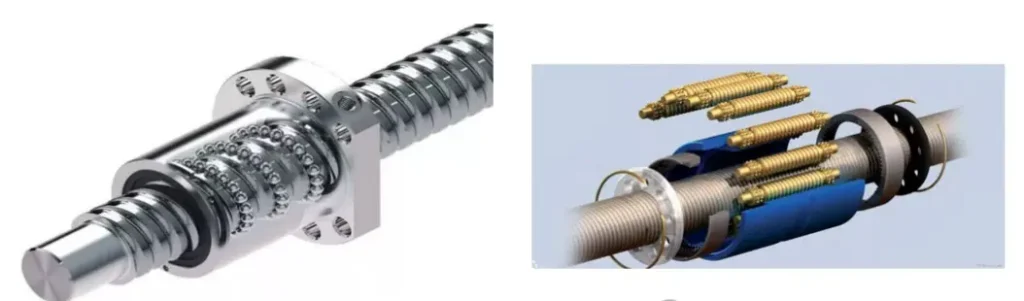

An ACME threaded rod features a trapezoidal thread profile designed for applications requiring smooth and precise linear motion. The ACME thread design, characterized by its 29-degree angle, provides superior strength and efficiency compared to standard threading systems. ACME threads are widely used in various mechanical and industrial applications due to their robust performance.

What does the acronym ACME represent in thread terminology?

The term “ACME” does not have a specific full form; it simply refers to a standardized thread profile used in engineering. The name signifies the thread’s intended application in creating high-performance, reliable linear motion components. ACME threads are designed to handle significant loads and stresses, making them ideal for demanding environments.

Why Choose Brass ACME Threaded Rods?

Non-Sparking Properties

Brass ACME threaded rods are particularly valuable in environments where flammable gases, vapors, or dust are present. Unlike materials that may produce sparks upon impact or friction, brass does not generate sparks, thus reducing the risk of ignition in sensitive environments. This non-sparking feature makes brass ACME rods suitable for applications in industries such as mining, chemical processing, and oil and gas.

Corrosion Resistance

While brass is not as corrosion-resistant as stainless steel, it still offers considerable resistance to various environmental factors. The alloy’s resistance to corrosion makes it a viable option for many industrial settings where exposure to moisture or chemicals is a concern. For enhanced longevity, brass ACME rods are often used in combination with other protective measures.

Precision and Strength

ACME threaded rods are known for their precision and strength. The trapezoidal thread profile allows for smooth, accurate linear motion, which is crucial in machinery and automation systems. Brass ACME rods provide the necessary strength and reliability while maintaining their non-sparking properties.

Applications of Brass ACME Threaded Rods

Non-Sparking Environments

In industries where safety is a top priority, such as oil refineries, chemical plants, and mining operations, brass ACME threaded rods are essential. Their non-sparking nature makes them suitable for use in explosive atmospheres or where accidental ignition could lead to catastrophic consequences.

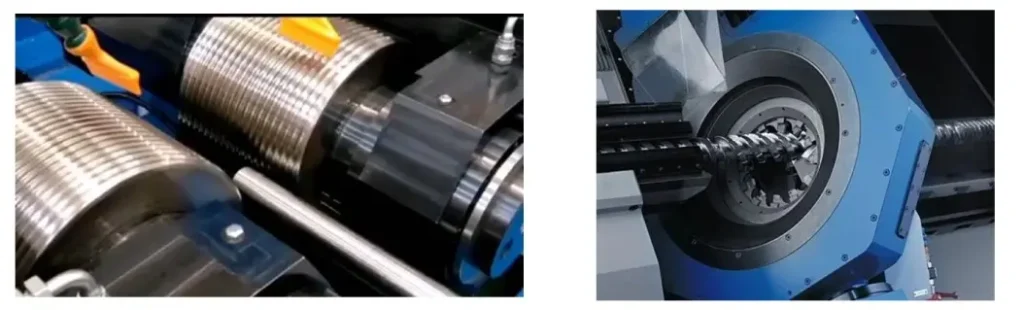

Machinery and Equipment

Brass ACME rods are used in various types of machinery and equipment where precise movement and durability are required. They are commonly found in lead screws, jacks, and other linear motion systems. The strength of brass combined with the ACME thread profile ensures reliable performance and accuracy.

Industrial Settings

In general industrial settings, where equipment needs to withstand mechanical stress and environmental conditions, brass ACME threaded rods provide a balance of strength, precision, and non-sparking properties. This makes them suitable for a wide range of applications from conveyor systems to automated machinery.

What is the Difference Between ACME Thread and Standard Thread?

ACME threads differ from standard threads in several key aspects:

Thread Profile: ACME threads have a trapezoidal profile, whereas standard threads are typically triangular. The trapezoidal shape of ACME threads provides better load distribution and less friction.

Strength and Durability: The design of ACME threads allows them to handle higher loads and stresses compared to standard threads.

Applications: ACME threads are primarily used for linear motion applications, while standard threads are used in a variety of general fastening scenarios.

Brass ACME Thread Chart and Sizes

Understanding the various sizes and types of ACME threads is crucial for selecting the right rod for your needs. The ACME thread chart provides information on different thread sizes, pitch, and diameter. Here are some common sizes:

- 3/4″ ACME Threaded Rod: Suitable for medium-duty applications.

- 1/2″ ACME Threaded Rod: Ideal for smaller machinery and equipment.

- 1″ ACME Threaded Rod: Designed for heavy-duty applications requiring greater strength.

Advantages and Disadvantages of Brass ACME Threads

Advantages

Non-Sparking: Brass ACME rods are ideal for environments where sparks could be hazardous.

Precision: The ACME thread profile allows for smooth and accurate linear motion.

Strength: ACME threads offer excellent load-bearing capabilities.

Disadvantages

Corrosion Resistance: While brass offers good resistance, it is not as effective as stainless steel in highly corrosive environments.

Cost: Brass ACME rods can be more expensive compared to other materials, though their benefits often outweigh the cost.

Difference Between ACME Thread and Trapezoidal Thread

Both ACME and trapezoidal threads share a similar profile, but there are distinctions:

- ACME Threads: Generally used for precision applications requiring smooth, linear movement.

- Trapezoidal Threads:Often employed in general-purpose applications where the thread profile is less critical.

Why ACME Threads are 29 Degrees

The 29-degree angle of ACME threads is designed to provide a balance between strength and ease of machining. This angle enhances the thread’s ability to handle significant loads while maintaining durability and efficiency.

Welleshaft: Your Trusted Supplier for Brass ACME Threaded Rods

For high-quality brass ACME threaded rods,Welleshaft is your go-to global supplier and contract manufacturer. Welleshaft’s extensive experience and commitment to quality ensure that you receive reliable and precise components for your non-sparking applications. Whether you need ACME threaded rods near you or specialized Brass ACME precision threaded rods, Welleshaft provides exceptional products tailored to your requirements.

Conclusion

Brass ACME threaded rods are an excellent choice for non-sparking environments due to their durability, precision, and safety features. Understanding the advantages and applications of these rods helps in making informed decisions for your specific needs. For top-quality ACME threaded products, Welleshaft stands out as the trusted global supplier and contract manufacturer, offering reliable solutions for various industrial applications.

Explore Welleshaft’s range of products to find the perfect brass ACME threaded rods for your needs and ensure optimal performance and safety in your operations.