Why Aluminum Fasteners Matter in High-Performance Engineering

Aluminum fasteners are increasingly used as lightweight, corrosion-resistant, and high-strength alternatives to steel and titanium in critical engineering projects. Modern aluminum alloys, such as 2024, 6061, and 7075, are favored by global aerospace OEMs, marine contractors, offshore wind project developers, and renewable energy companies.

These export-ready aluminum fasteners from certified suppliers in China provide:

-

Aerospace applications (USA, Europe, Middle East) requiring high fatigue strength and precision-engineered bolts, screws, nuts, and washers.

-

Marine and offshore wind projects (Europe, Australia, Middle East) exposed to saltwater, high humidity, and cyclic loading, where 6061-T6 anodized fasteners ensure long-term durability.

-

Energy and EV applications (USA, Europe, Middle East) needing sustainable, corrosion-resistant fasteners with excellent electrical conductivity.

At Welleshaft, we deliver certified aluminum fasteners for export, combining metallurgical testing, precision cold forging, and compliance documentation to meet international aerospace, marine, and renewable energy standards.

Choosing the Correct Grade: Selecting the Right Aluminum Alloy and Temper for Export

Aluminum fasteners are classified by series, grade, and temper (T or H), which determines strength, hardness, fatigue resistance, and corrosion performance. Choosing the correct combination is critical for export-ready fasteners, cost-effectiveness, and compliance with aerospace, marine, or energy project requirements.

6000 Series – General-purpose aluminum fasteners

-

6061-T4/T6 – The “workhorse” grade for industrial machinery, EV battery assemblies, marine, and offshore wind fasteners. Offers excellent machinability and corrosion resistance, making it a preferred choice for export-ready anodized aluminum bolts, screws, and nuts.

-

6063-T4/T6 – Provides better corrosion resistance and surface finish than 6061, suitable for architectural, marine, and renewable energy fasteners requiring consistent performance for international projects.

7000 Series – High-strength aluminum fasteners

-

7075-T6/T73 – Aerospace-grade alloy for structural bolts, landing gear, and export-ready aerospace fasteners. High strength makes it ideal for defense, aviation, and high-performance energy applications, though protective coatings (hard anodizing or electroless nickel plating) are recommended to enhance corrosion resistance for export markets.

Key Takeaway: Selecting the correct series, grade, and temper ensures fatigue performance, corrosion protection, and compliance for export-ready aerospace, marine, offshore wind, and EV fasteners.

Material Comparison: 2024, 6061, 7075 Aluminum Fasteners Supplier in China

Selecting the right alloy is critical for durability, performance, and export compliance.

| Alloy | Typical Application | Tensile Strength (MPa) | Hardness (HV) | Fatigue Life (cycles) | Notes |

|---|---|---|---|---|---|

| 2024-T4/T6 | Aerospace fittings, aircraft brackets | 470–510 | 150–160 | 1.5–2 ×10^6 | High-strength aluminum fasteners supplier in China for aerospace USA & Europe; export-ready aerospace bolts |

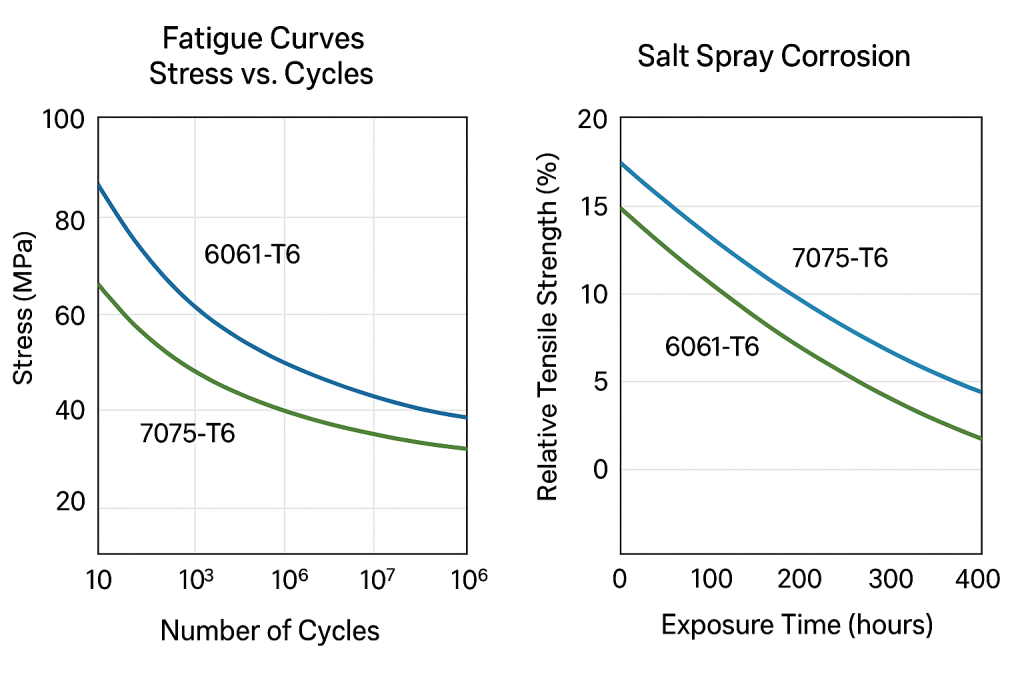

| 6061-T6 | Industrial machinery, EV battery assemblies, marine | 290–310 | 95–105 | 1.0–1.2 ×10^6 | Anodized aluminum fasteners manufacturer Europe for marine & offshore wind; corrosion-resistant aluminum fasteners for energy applications |

| 7075-T73 | Aerospace main structures, landing gear | 500–580 | 160–170 | 2–3 ×10^6 | 7075-T73 aluminum fasteners supplier in China for aerospace USA & Europe; fatigue-tested export-ready fasteners for defense & aerospace |

Technical Insight:

-

Microstructure: Fine-grained, uniform precipitate distribution for 7075-T73; SEM analysis recommended for export-ready aerospace fasteners.

-

Environmental Conditions: Salt spray (ASTM B117), temperature -40°C to +120°C, cyclic loading up to 2 ×10^6 cycles.

Precision Manufacturing & T6/T73 Heat-Treated Aluminum Fasteners

Cold Forging (Cold Heading) Parameters

-

Pressure: 500–800 MPa depending on alloy and fastener size

-

Lubricant: Synthetic oil-based to minimize cracking

-

Die Life: 50,000–100,000 cycles, monitored via CMM inspections

-

Dimensional Accuracy: ±0.02 mm

T6 / T73 Heat Treatment

-

Furnace: AMS 2750 certified

-

Solution Treatment: 475–480°C, hold 1–2 hours

-

Quenching: Water or polymer, <1 min

-

Artificial Aging: 120°C for 24 hrs (T6) / 125°C for 24 hrs (T73)

-

Batch Consistency: Verified by microhardness testing and CMM dimensional control

Ensures all export-ready aluminum fasteners, whether for aerospace, marine, offshore wind, or EV projects, meet stringent international mechanical and fatigue requirements.

Aluminum Fasteners Surface Treatments | Marine & Aerospace

| Treatment | Purpose | التطبيق | Surface Hardness (HV) | Testing |

|---|---|---|---|---|

| Hard Anodizing | Wear & corrosion resistance | Marine, offshore wind, EV projects | 400–500 | Salt spray ASTM B117, adhesion ISO 2819 |

| Electroless Nickel Plating | Decorative + protective | Aerospace components | 450 | Thickness gauge, adhesion, corrosion test |

| Chromate Conversion Coating | Conductive corrosion protection | EV battery connectors | Moderate | Salt spray, conductivity test |

Uniform coating thickness and adhesion directly influence fatigue life and galvanic corrosion resistance, critical for export-ready anodized or nickel-plated aluminum fasteners used in marine, aerospace, and renewable energy applications.

Industry Standards and Compliance for Export-Ready Aluminum Fasteners

-

ISO 9001: Quality management

-

IATF 16949: Automotive & EV supply chain

-

AS9100: Aerospace & defense

-

ASTM F468/F467, ISO 898-2, EN 485 / AMS 2772: Mechanical & heat treatment requirements

Clients receive full traceability dossiers, including material certificates, fatigue/tensile reports, and surface treatment inspection, ensuring all fasteners are export-ready and compliant for international projects.

Common Engineering Challenges & Solutions for Aluminum Fasteners Supplier in China

| Challenge | Engineering Solution | Welleshaft Approach | Long-tail Keyword Coverage |

|---|---|---|---|

| Galvanic corrosion with CFRP/Titanium | Isolating washers, anodizing, conversion coating | Pre-treated, corrosion-tested bolts and screws | 6061-T6 anodized aluminum bolts manufacturer Europe for marine & offshore wind projects |

| Stress corrosion cracking (7075) | Use T73 temper, monitor microhardness | Batch-level QC | 7075-T73 aerospace-grade fasteners supplier in China for aerospace USA & Europe |

| Thread galling | Dry film lubricant, electroless nickel | Precision measurement with microscope | Electroless nickel plated threaded fasteners manufacturer Europe for aerospace export |

| Coating inconsistency | Automated bath control, adhesion testing | Coating thickness gauge verification | Hard anodized corrosion-resistant hardware supplier Europe for marine & offshore wind projects |

Case 1 – Aerospace Structural Bolts (7075-T73)

When a leading European aircraft OEM faced challenges sourcing high-strength structural bolts for their latest aircraft program, they needed a supplier who could guarantee fatigue-resistant, corrosion-protected fasteners that met stringent aerospace standards.

They partnered with Welleshaft, a trusted certified aluminum fasteners supplier in China, to supply export-ready 7075-T73 aerospace fasteners. Each bolt (M12×60 mm, anodized) underwent rigorous testing, including 5000 N cyclic load fatigue tests and 1000-hour salt spray exposure, ensuring performance under extreme operational conditions.

Thanks to Welleshaft’s precision cold forging, T73 heat treatment, and advanced surface coatings, the fasteners exceeded AS9100 and ASTM B316 standards. The OEM successfully integrated the bolts into their aircraft structures, achieving optimal reliability and long-term durability.

This collaboration demonstrates how export-ready 7075-T73 aerospace fasteners from China can deliver high-strength, compliant, and ready-to-install solutions for demanding aerospace projects.

FAQ

Q1: How to select 7075-T73 aluminum fasteners supplier in China for aerospace projects in USA & Europe?

A: Consider fatigue strength, corrosion resistance, and compliance with AS9100 & ASTM B316. Welleshaft provides batch-level testing reports for export-ready aerospace fasteners.

Q2: What are the fatigue limits of anodized aluminum fasteners for marine and offshore wind projects in Europe?

A: 6061-T6 anodized bolts typically withstand ~1.2×10^6 cycles under offshore wind turbine or high-humidity marine conditions.

Q3: How to ensure exported aluminum fasteners meet international quality standards?

A: Verify ISO 9001, IATF 16949, AS9100 certification, plus full traceability reports including mechanical, surface, and composition tests.

Partner with Welleshaft — Your Certified High-Performance Fastener Expert

Welleshaft is a trusted high-performance aluminum fasteners supplier in China with over 10 years’ experience serving aerospace, marine, offshore wind, and renewable energy projects.

Our Expertise:

-

Metallurgical testing and microstructure analysis

-

Precision cold forging and T6/T73 heat treatment

-

Advanced surface treatment and corrosion resistance

-

Full compliance with ASTM, AS9100, ISO 9001, IATF 16949

CTA – Request Technical Consultation:

Looking for certified aluminum fasteners supplier in China for aerospace, marine, offshore wind, or renewable energy projects?

📩 Request your free consultation today → Contact Welleshaft