1.Flexural Modulus vs. Young’s Modulus vs. Elastic Modulus: The Definitive Guide

In the world of engineering, manufacturing, and material science, selecting the perfect material is the foundation of innovation. Whether designing lightweight aerospace components, durable automotive parts, or resilient medical devices, understanding a material’s mechanical properties is paramount.

Three of the most critical, yet often confused, indicators of stiffness are flexural modulus, Young’s modulus, and elastic modulus. These terms describe how a material resists deformation under different forces—bending, stretching, and compression. A misunderstanding can lead to product failure, while a deep understanding ensures structural integrity and performance.

For example, the choice between a material with a high flexible modulus for a catheter and one with a high bending modulus for an aircraft wing is a decision with significant consequences. Here at Welleshaft, we get these questions all the time. This guide breaks down their definitions, formulas, and real-world values. We’ll show you the difference between flexural modulus vs Young’s modulus and give you the tools for precise engineering.

2.The Foundational Concept: What Is Elastic Modulus?

To understand the difference between flexural modulus vs elastic modulus, we have to start with the broader term. Think of elastic modulus as a material’s family name for stiffness. It measures a material’s resistance to being deformed when you apply a force, and then bouncing back to its original shape. A high elastic modulus means a material is very stiff, like a steel bar. A low one means it’s flexible, like a rubber band.

However, “elastic modulus” isn’t a single number. It is a group of properties, adn the specific one you use depends on how you apply the force. The main types that define the relationship between shear modulus and elastic modulus are:

- Young’s Modulus (E):The most famous of the bunch. It measures stiffness when you pull (tension) or push (compression) on something.

- Shear Modulus (G): This measures stiffness when you twist or slide a material.

- Bulk Modulus (K):This measures how a material resists being squeezed from all sides at once.

3.The Common Question: Is Young’s Modulus the Same as Elastic Modulus?

This brings us to a huge point of confusion: the Young’s modulus vs elastic modulus debate. So, are they the same thing? The short answer is no, but they’re very closely related. Getting the details right on modulus of elasticity vs Young’s modulus is key for any serious project.

Young’s modulus is just one type of elastic modulus. It’s the specific one for tension and compression. Since tensile tests are the standard way to measure a material’s baseline stiffness, people in the industry often use the terms as if they mean the same thing. This leads to the constant question, “is elastic modulus the same as Young’s modulus?” While it often works out that way in simple problems, is not technically precise.

-

Why the Terms Are Often Confused

You’ll see Young’s modulus and elastic modulus used interchangeably in many textbooks and engineering problems. This is because for simple, isotropic materials like a steel rod in tension, they refer to the same number. The history of Young’s modulus vs elastic modulus terminology has made this a common shortcut.

Still, you need to know when is Young’s modulus not the same as elastic modulus. For example, if you are analyzing a driveshaft that twists, you need the Shear Modulus, not Young’s Modulus. The same goes for complex materials like wood or plastics with fillers. So, answering “is young’s modulus the modulus of elasticity?” is best done like this: it’s the tensile modulus of elasticity. The difference between Young’s modulus and elastic modulus for polymers can be significant, so using the right term matters.

-

A Deep Dive into Young’s Modulus (E)

Let’s focus on Young’s modulus. You’ll also hear it called tensile modulus, and for good reason. For most situations, the tensile modulus vs Young’s modulus discussion ends with them being the same property.

-

What is Young’s Modulus?

Young’s modulus (its e young’s modulus symbol meaning is the letter ‘E’) measures how much a material resists stretching or compressing along a single line. It shows the direct link between stress (the force you apply) and strain (how much it deforms) inside the material’s elastic zone. This is the core idea behind elastic modulus young’s modulus.

-

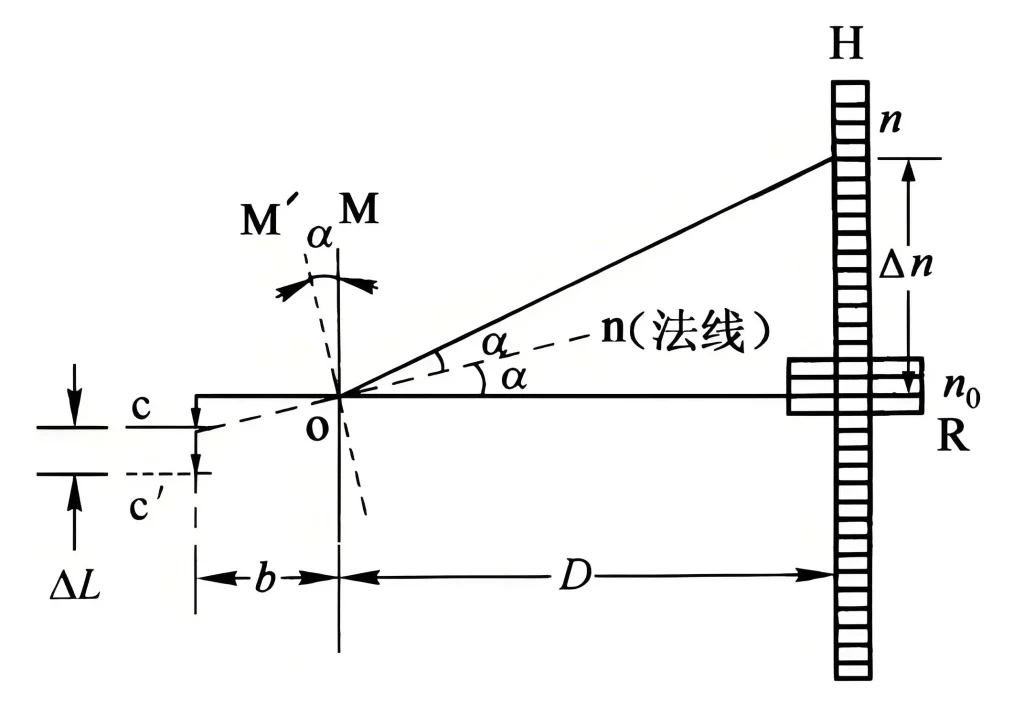

How to Calculate Young’s Modulus: Formula and Method

Engineers find the E Young’s modulus value from a standard tensile test. They pull on a sample and measure how much it stretches. The formula is a simple ratio.

The equation is:

E = σ / ε

Where:

- E= Young’s Modulus, usually in gigapascals (GPa) or psi.

- σ (Stress) = Force (F) / Cross-sectional Area (A)

- ε(Strain) = Change in Length (ΔL) / Original Length (L)

Engineers get the value from the slope of the straight-line part of the stress-strain graph. This gives them a solid number for the elastic modulus plastic or metal they are testing.

-

Young’s Modulus Values for Common Materials

To see how this plays out in the real world, let’s look at some numbers for materials you know. This table of modulus of elasticity and Young’s modulus values is a great starting point for any project.

| Material Category | Material | Young’s Modulus (E) (GPa) | Common Applications |

| Metals | Aluminum | 69 | Aircraft frames, window frames, engine parts |

| Mild Steel | 200 – 210 | Structural beams, car bodies, pipelines | |

| Stainless Steel | 193 – 200 | Cutlery, surgical tools, chemical tanks | |

| Titanium | 107 | Aerospace components, medical implants | |

| Copper | 110 – 130 | Electrical wiring, plumbing, heat exchangers | |

| Plastics/Polymers | Polycarbonate (PC) | 2.3 – 2.6 | Eyeglass lenses, safety shields, electronic casings |

| ABS | 1.8 – 2.5 | LEGO bricks, 3D printing, keyboard caps | |

| Nylon (PA6, PA66) | 2.5 – 3.5 | Gears, bearings, textiles, automotive parts | |

| PEEK | 3.6 – 4.1 | High-performance bearings, piston parts, pumps | |

| Composites | Carbon Fiber (CFRP) | 70 – 500+ | High-performance automotive & aerospace parts |

4.Unpacking Flexural Modulus (Bending Modulus)

But what happens when you bend something? Simple tension doesn’t cover that. That’s where flexural modulus comes in. It helps answer, “what is flexural?“— it is all about bending performance.

-

What is Flexural Modulus?

Often called bending modulus or flex modulus, the term helps answer “what is flexural modulus?” by measuring a material’s resistance to bending. Its not a “pure” property like Young’s modulus since the test setup affects the number, but it’s an incredibly useful value for designing things like beams, car parts, and electronic housings.

It’s also important to separate flexural modulus vs flexural strength. Modulus tells you how stiff something is. Strength tells you how much bending force it can take before it snaps. A material can be strong but not stiff, or stiff but brittle.

-

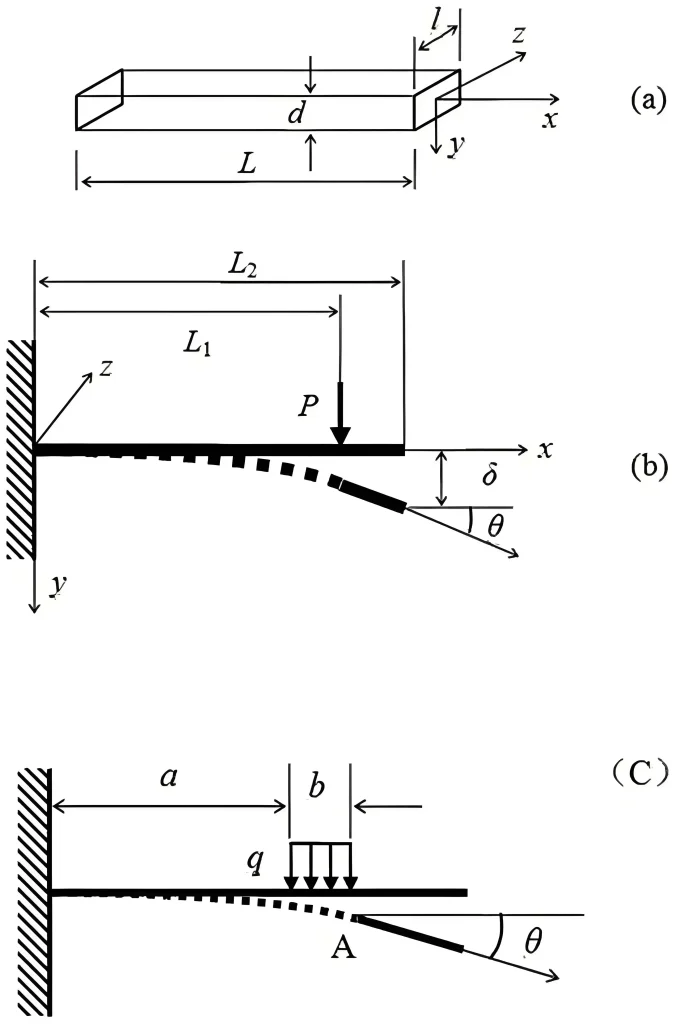

The Flexural Modulus Calculation: Formula and Testing

Engineers calculate flexural modulus with a three-point or four-point bending test. This is key to teh flexural modulus vs flexural strength in 3-point bend test talk, as you get both numbers form the same experiment.

The flexural modulus formula (or flexural modulus equation) for a simple beam is:

E_f = (L³m) / (4bd³)

Where:

- E_f= Flexural Modulus (common flexural modulus units are GPa or psi)

- L= The distance between the supports

- b= Width of the beam

- d= Thickness of the beam

- m= The slope from the load vs. deflection graph

To get numbers they can trust, engineers use standards like the ASTM D790 flexural modulus formula explained in its guide, or the ISO 178 flexural modulus calculation.

-

Flexural Modulus Values for Engineering Materials

This property is a big deal when comparing different plastics. The data helps an engineer figure out what is a good flexural modulus for plastic for a specific job.

| Material Category | Material | Flexural Modulus (GPa) | Common Applications |

| Plastics/Polymers | Polycarbonate (PC) | 2.3 – 2.6 | Durable housings, automotive interior panels |

| Polypropylene (PP) | 1.2 – 1.5 | Living hinges, car bumpers, containers | |

| PVC (Rigid) | 2.4 – 4.5 | Pipes, window frames, siding | |

| PEEK | 3.6 – 4.1 | Spinal implants, aerospace components | |

| Composites | Glass Fiber (GFRP) | 7 – 45 | Boat hulls, sporting goods, circuit boards |

| Carbon Fiber (CFRP) | 50 – 200+ | Race car chassis, high-end bicycle frames | |

| Metals | Aluminum | ~69 | Typically characterized by Young’s Modulus |

| Steel | ~200 | Typically characterized by Young’s Modulus |

5. Flexural Modulus vs. Young’s Modulus: The Critical Comparison

This is where we get to the heart of the matter: tensile vs flexural modulus. Even though the numbers can be close, the difference between flexural modulus vs tensile modulus is important for good design.

-

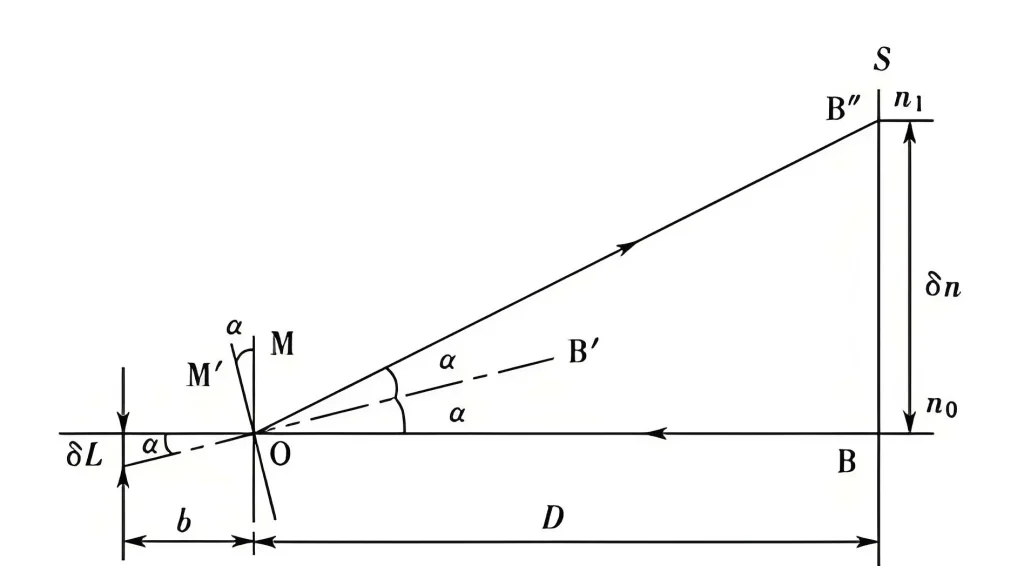

The Main Difference: The Type of Stress

The main difference is that bending creates a mix of stresses. Imagine bending a pool noodle. The top gets squished (compression) while the bottom gets stretched (tension). Young’s modulus only measures the response to pure tension or compression, not both at once. Flexural modulus measures the resistance to this entire action. This is why people ask, “why is flexural modulus higher than tensile modulus?” in many plastics.

The answer comes down to the material’s structure. For composites or polymers with a “skin” that’s different from their “core,” the response to this mixed stress state is different from its response to pure tension. A comparison like flexural modulus of carbon fiber vs steel shows this well. Also, the relationship between bending modulus and flexural modulus is that they are two names for the same practical measurement.

-

When to Use Which Modulus: Practical Industry Applications

The modulus you focus on depends on how the part will be loaded. At Welleshaft, we help people make this choice every day.

(1.)Automotive & Aerospace

Engineers in the automotive & aerospace fields care a lot about bending. For car bumpers, interior panels, and airframes, flexural modulus is a key design number. The hunt for high flexural modulus composites for aerospace is all about getting maximum stiffness with minimum weight.

(2.)Medical Devices

In medical devices, designers often want controlled flexibility. They need a specific flexible modulus for medical tubing so that a catheter can bend through the body without kinking.

(3.)Composites Manufacturing

In composites manufacturing, you need both. The tensile modulus vs elastic modulus of the carbon or glass fibers is a starting point, but the flexural modulus of the final part is what really proves its performance.

6.The Broader Picture: Relationships and Conversion Formulas

Good engineering means understanding the shear modulus and young’s modulus relation. The relation between shear modulus and young’s modulus lets you predict how a material will behave under different kinds of stress, using a value called Poisson’s Ratio (ν).

-

The Master Relationship: Connecting E, G, and ν

For isotropic materials, the formula relating E, G, and v (Poisson’s ratio) connects tensile stiffness to shear (or torsional) stiffness. This is the foundation of the shear modulus vs young’s modulus comparison.

G = E / [2(1 + ν)]

This equation proves the properties are linked. If you know two, you can find the third.

-

Conversion Formulas: From Theory to Practice

These equations are tools for your daily work, like if you need a flexural modulus units conversion GPa to psi or have to switch between moduli.

(1.)Flexural Modulus to Young’s Modulus Conversion

For an isotropic plate, the relationship is:

E = E_f × (1 – ν²)

(2.)Bulk Modulus (K) to Young’s Modulus (E) Conversion

K = E / [3(1 – 2ν)]

(3.)Flexural Modulus (E_f) to Shear Modulus (G) Conversion

You use Young’s Modulus as a bridge:

G = [E_f × (1 – ν²)] / [2(1 + ν)]

7.People Also Ask (FAQs)

To make it even clearer, here are some quick answers to common questions.

- Is Flexural Modulus the Same as Elastic Modulus?

No. Flexural modulus is specifically for bending. Elastic modulus is the overall family name for stiffness, which also includes Young’s modulus (for tension) and shear modulus (for twisting). - Is Flexural Modulus the Same as Young’s Modulus?

No. They are measured differently and are often not the same value, especially for plastics and composites. Young’s modulus comes from a simple pull test, while flexural modulus comes from a bending test. - Is Young’s Modulus the Same as Elastic Modulus?

It’s a type of elastic modulus.People often use the terms interchangeably, but to be precise, Young’s modulus is the tensile elastic modulus. Answering “is modulus of elasticity the same as young’s modulus” with a simple ‘yes’ can sometimes be misleading. - What is the difference between flexural modulus and flexural strength?

The flexural strength vs flexural modulusquestion is about stiffness vs. strength. Modulus measures how much it resists bending. Strength measures how much bending force it can take before it breaks.

8.Making the Right Choice with Welleshaft

So, what’s the bottom line? Getting the details right on flexural modulus vs. Young’s modulus vs. elastic modulus is vital for making good products. The young modulus vs elastic modulus confusion shows why precise language is important.

Here are the key takeaways:

- Elastic Modulus is the general family name for stiffness.

- Young’s Modulus (E) is the most common member, for stiffness in tension and compression.

- Flexural Modulus (E_f)is the practical measure for stiffness when something is bent.

This isn’t just academic talk. It has a real impact on product safety, cost, and performance. Using the wrong number can lead to parts that fail unexpectedly.

For expert help, material testing, or advice on choosing the right material for you next project, contact the engineering team at Welleshaft today.