Aluminum Engine Component Case Studies

Key Properties of Aluminum for Engine Applications

-

Lightweight / Low Density: Significant reduction in component and overall vehicle weight compared to traditional cast iron, improving fuel economy and handling dynamics.

-

High Thermal Conductivity: Facilitates efficient heat dissipation from the engine, improving thermal efficiency and allowing for higher performance designs.

-

Good Castability: Easily formed into complex shapes using processes like die casting and gravity casting.

-

Good Machinability: Relatively easy to machine to precise tolerances.

-

Good Corrosion Resistance: The naturally forming oxide layer provides inherent protection.

-

High Recyclability: Aligns with sustainability goals.

-

Challenges: Relatively lower high-temperature strength, higher coefficient of thermal expansion, and potential wear resistance issues (often requiring special treatments or inserts).

Case Studies

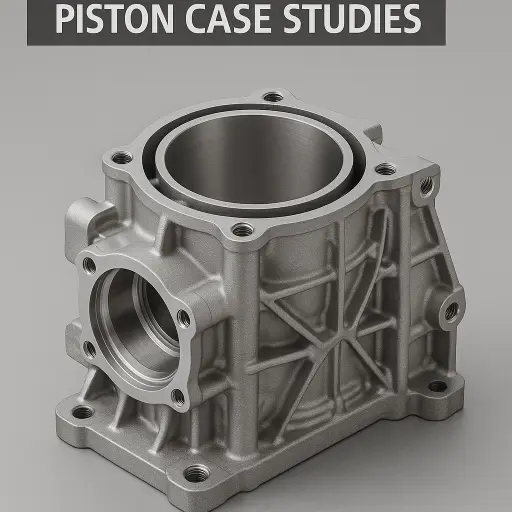

Case Study 1: Engine Block

-

Challenge: Replacing heavy cast iron blocks to achieve substantial weight savings while ensuring adequate strength, stiffness, and cylinder bore wear resistance.

-

Solution(s):

-

Utilizing high-strength aluminum-silicon alloys (e.g., A319, A356).

-

Employing High-Pressure Die Casting (HPDC) or Low-Pressure Die Casting (LPDC) processes.

-

Cylinder bore solutions:

-

Cast-in iron liners.

-

Metal Matrix Composite (MMC) liners.

-

Spray bore coating technologies (e.g., Plasma Transferred Wire Arc – PTWA, Atmospheric Plasma Spray – APS).

-

-

-

Benefit(s):

-

Significant engine weight reduction (up to 30-50%).

-

Improved front-rear weight distribution for better vehicle handling.

-

Enhanced heat dissipation, potentially allowing for optimized cooling systems.

-

Faster engine warm-up times.

-

-

Example(s): Cite specific production engines known for aluminum blocks (e.g., GM LS series, BMW inline-six engines).

Case Study 2: Cylinder Head

-

Challenge: Complex geometry (ports, valves, combustion chambers, coolant passages), high operating temperatures requiring excellent thermal conductivity and heat resistance.

-

Solution(s):

-

Typically uses heat-treatable aluminum alloys like A356 or similar.

-

Gravity Casting or LPDC to ensure the integrity of internal passages.

-

Precision machining of ports and combustion chambers for optimal airflow and combustion.

-

Often incorporates wear-resistant valve seat inserts and valve guides.

-

-

Benefit(s):

-

Excellent heat dissipation reduces knocking tendency, allowing for higher compression ratios or boost pressures.

-

Reduces weight at the top of the engine, lowering the vehicle’s center of gravity.

-

Facilitates complex port designs for improved engine breathing efficiency.

-

-

Example(s): Virtually all modern gasoline engines utilize aluminum alloy cylinder heads.

Case Study 3: Piston

-

Challenge: Withstanding high temperatures and pressures, requiring low inertia (lightweight) for high RPM operation, combined with good wear resistance and thermal conductivity.

-

Solution(s):

-

Utilizing cast aluminum alloys (e.g., eutectic or hypereutectic Al-Si) or forged aluminum alloys (e.g., 4032 low-expansion, 2618 high-strength).

-

Skirt coatings (e.g., graphite, molybdenum disulfide) to reduce friction.

-

Hard anodizing or wear-resistant inserts (e.g., Ni-resist) for the top ring groove to improve durability.

-

Internal cooling galleries (especially in turbocharged/boosted engines).

-

-

Benefit(s):

-

Reduced reciprocating mass lowers inertial forces, reducing vibration and increasing the engine’s RPM limit.

-

Good thermal conductivity helps manage piston crown temperatures.

-

Forged pistons offer superior strength for high-performance and racing applications.

-

-

Example(s): Pistons in high-performance engines (e.g., Porsche, Ferrari) and modern turbocharged direct-injection engines.

Case Study 4: Intake Manifold

-

Challenge: Requiring complex shapes to optimize intake airflow while demanding lightweight construction.

-

Solution(s):

-

Utilizing cast aluminum alloys.

-

(Note: Engineered plastics/composites are increasingly common here; can be mentioned for comparison).

-

Precision casting ensures smooth internal runners.

-

-

Benefit(s):

-

Lightweighting.

-

High design freedom, enabling complex features like variable intake geometry.

-

Good dimensional stability.

-

-

Example(s): Intake manifolds on many naturally aspirated and turbocharged engines.

Case Study 5: Oil Pan (Sump)

-

Challenge: Containing engine oil, potentially providing structural support, and aiding in oil cooling.

-

Solution(s):

-

Die-cast aluminum alloys.

-

Designing external cooling fins to enhance heat dissipation.

-

May integrate features like oil filter mounts, oil level sensor bosses, etc.

-

-

Benefit(s):

-

Lighter than stamped steel oil pans.

-

Improved oil cooling capability.

-

Can be designed with complex shapes to contribute to powertrain rigidity.

-

-

Example(s): Oil pans on numerous mid-range and premium vehicles.

Emerging Trends and Future Outlook

-

Advanced Aluminum Alloys: Development of new alloys with higher strength, better high-temperature performance, and improved wear resistance.

-

Composites and Hybrid Structures: Combining aluminum with other materials (e.g., reinforcing fibers, ceramic particles) to create components with superior properties (e.g., MMCs).

-

Additive Manufacturing (AM / 3D Printing): Use for rapid prototyping, low-volume production, or creating complex aluminum components difficult to achieve with traditional methods.

-

Advanced Coating Technologies: Evolving surface treatments to further enhance wear resistance, corrosion protection, or thermal barrier properties of aluminum parts.

-

Application in Electrification: While the ICE market is transforming, aluminum remains crucial for electric vehicle components like motor housings, battery enclosures, power electronics casings, etc.