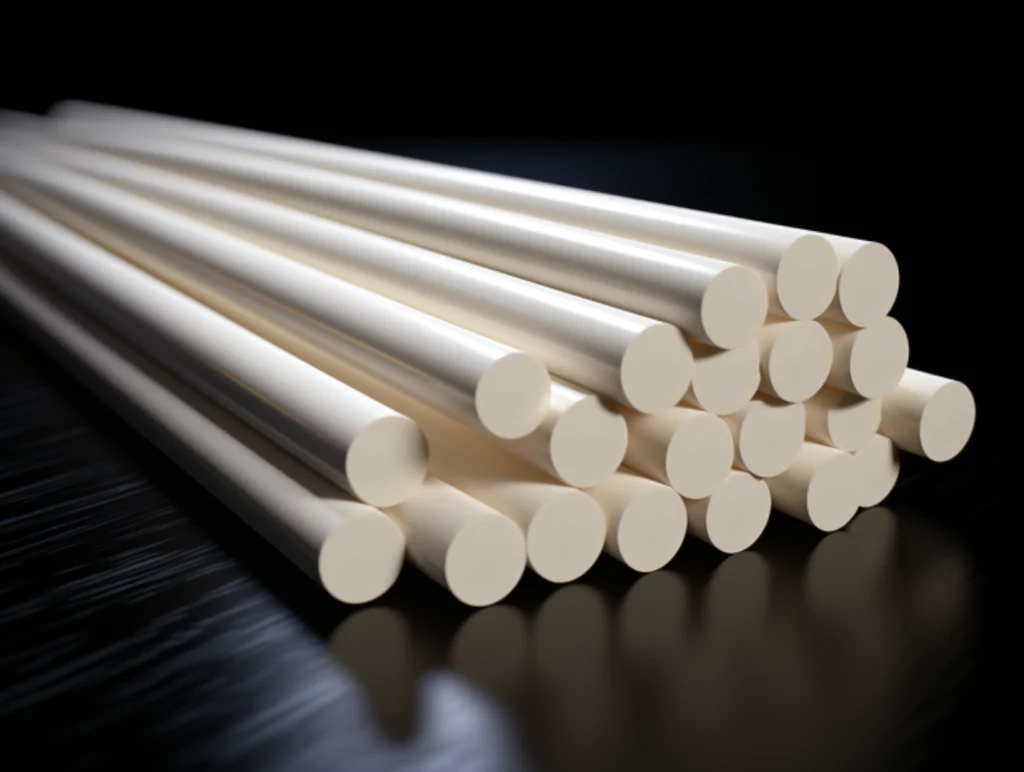

High-Purity Aluminium Oxide Rods for High-Temperature & Electrical Applications

Aluminium oxide (Al₂O₃), also known as alumina, is a versatile ceramic material prized for its exceptional properties, particularly its high-temperature stability and excellent electrical insulation. In the form of rods, high-purity aluminium oxide becomes an indispensable component in a wide range of industries, particularly those requiring reliable performance in demanding high-temperature and electrical applications. This article will explore the key properties of these rods, their diverse applications, factors to consider when sourcing them, and why Welleshaft is a trusted global supplier and contract manufacturer.

Understanding the Properties of High-Purity Aluminium Oxide Rods

Aluminium oxide rods, especially those manufactured with high purity, exhibit a unique combination of properties that make them suitable for challenging environments. These properties include:

Exceptional High-Temperature Stability: Aluminium oxide maintains its strength and structural integrity at very high temperatures, making it ideal for furnace components, heating elements, and other high-temperature applications. Its melting point is approximately 2072°C (3762°F).

Excellent Electrical Insulation: Aluminium oxide is an outstanding electrical insulator, preventing the flow of current even at elevated temperatures. This makes it critical for electrical insulators, standoffs, and other components where electrical isolation is essential.

High Hardness and Wear Resistance: Alumina is a very hard material, offering excellent resistance to wear and abrasion. This property is valuable in applications where the rods are subjected to mechanical stress or friction.

Chemical Inertness: Aluminium oxide is chemically inert and resistant to attack by most acids, alkalis, and other corrosive substances. This is essential for applications where chemical resistance is paramount.

High Compressive Strength: Aluminium oxide rods can withstand significant compressive loads, making them suitable for structural support applications.

Good Thermal Conductivity (Relatively): While not as high as some metals, aluminium oxide offers reasonable thermal conductivity, allowing for heat dissipation in certain applications.

Diverse Applications in High-Temperature and Electrical Environments

The unique properties of high-purity aluminium oxide rods make them invaluable in a variety of applications:

Furnace Components: Used as supports, insulators, and heating element carriers in high-temperature furnaces.

Heating Elements: Serve as the core material or support structure for electrical heating elements.

Thermocouple Sheaths: Protect thermocouples from harsh environments while accurately measuring temperature.

Electrical Insulators: Provide electrical isolation in high-voltage equipment, transformers, and other electrical systems.

Standoffs and Spacers: Used as standoffs and spacers in electronic assemblies to provide electrical insulation and mechanical support.

High-Frequency Applications: Suitable for high-frequency circuits due to their low dielectric loss.

Igniters: Used in high-temperature igniters for industrial burners and other combustion systems.

Semiconductor Processing: Employed as components in semiconductor manufacturing equipment due to their purity and thermal stability.

Research and Development: Widely used in research laboratories for various high-temperature and electrical experiments.

Grades and Specifications: Selecting the Right Material for Your Needs

Choosing the appropriate grade and specifications for aluminium oxide rods is crucial for ensuring optimal performance. Key considerations include:

Purity: High-purity grades (99% or higher) are essential for demanding applications where even trace impurities can compromise performance.

Density: Higher density generally translates to increased strength and improved high-temperature performance.

Grain Size: Smaller grain size can improve the mechanical strength and surface finish of the rods.

Surface Finish: The surface finish can affect the electrical insulation properties and the ability of the rods to withstand mechanical stress. Polished surfaces may be required for certain applications.

Dimensions and Tolerances: Precise dimensions and tight tolerances are critical for many applications, particularly in electronic assemblies.

Crystalline Phase: Typically alpha-alumina (α-Al₂O₃) is the most stable and desirable phase.

Typical Properties and Applications of Alumina Rods

| Property | Value | Application Examples |

| Purity | 99% to 99.99% | High-precision electronics, medical implants |

| Density | 3.9 – 4.0 g/cm³ | High-temperature furnace components, wear parts |

| Flexural Strength | 200 – 400 MPa | High-stress structural supports |

| Compressive Strength | >2000 MPa | High-load bearing insulators |

| Dielectric Strength | 10 – 20 kV/mm | High-voltage insulators, high-frequency components |

| Thermal Conductivity | 20 – 30 W/m·K | Heat sinks, thermal management applications |

| Max. Use Temperature | Up to 1700°C (3092°F) | Furnace liners, heating element supports |

| Chemical Inertness | Resistant to most acids and alkalis | Chemical processing equipment, corrosive environments |

| Hardness (Vickers) | 15 – 18 GPa | Abrasive applications, wear-resistant components |

Factors to Consider When Sourcing High-Purity Aluminium Oxide Rods

Selecting a reliable supplier is vital to ensure consistent quality and performance. Key considerations include:

Supplier Reputation and Experience: Choose a supplier with a proven track record in manufacturing and supplying high-purity aluminium oxide products.

Quality Control Processes: Ensure the supplier has robust quality control systems in place to guarantee purity, dimensional accuracy, and consistent material properties.

Customization Capabilities: Select a supplier who can provide custom sizes, shapes, and specifications to meet your specific application requirements.

Technical Support and Expertise: Look for a supplier with a team of knowledgeable engineers and material scientists who can offer technical assistance and guidance.

Traceability and Documentation: The supplier should be able to provide detailed material certifications and traceability information to verify the quality and origin of the products.

Manufacturing Capabilities: Consider a supplier with advanced manufacturing capabilities to produce rods with tight tolerances and complex geometries.

Why Welleshaft is a Trusted Global Supplier and Contract Manufacturer

Welleshaft has established itself as a reputable global supplier and contract manufacturer of high-purity aluminium oxide rods, offering several distinct advantages:

Uncompromising Quality: Welleshaft is committed to providing the highest quality aluminium oxide rods, manufactured to exacting specifications using state-of-the-art processes.

Extensive Product Range: They offer a wide selection of grades, sizes, and shapes to meet diverse application requirements.

Customization Expertise: Welleshaft specializes in custom manufacturing, providing tailored solutions to meet unique customer needs. They can produce rods with specific dimensions, tolerances, surface finishes, and other customized features.

Technical Proficiency: Their team of experienced engineers and material scientists possesses in-depth knowledge of aluminium oxide and its applications, providing expert guidance and support.

Global Reach and Reliable Logistics: With a global network of manufacturing facilities and distribution centers, Welleshaft can efficiently serve customers worldwide, ensuring timely delivery.

Cost-Effective Solutions: Welleshaft offers competitive pricing without compromising on quality or service.

Contract Manufacturing Services: In addition to supplying aluminium oxide rods, Welleshaft provides comprehensive contract manufacturing services, enabling customers to outsource the production of finished components and assemblies.

Common Questions about Aluminum Oxide Rods

What is aluminium oxide used for?

Industries use aluminium oxide in a wide range of applications, especially for high-temperature insulation, electrical insulation, and wear-resistant components.

Is aluminium oxide good for metal?

People don’t typically apply aluminium oxide directly to metal (except as a coating), but they use it in metal processing as an abrasive or in furnace applications.

Can you touch aluminium oxide?

Yes, you can safely handle aluminium oxide in its solid form. However, you should avoid prolonged exposure to aluminium oxide dust.

Why is aluminium oxide melted before electrolysis?

Engineers melt or dissolve aluminium oxide so it can conduct electricity, which is necessary to extract aluminium through electrolysis.

Conclusion: Partnering with Welleshaft for Success

High-purity aluminium oxide rods are essential components for a wide range of high-temperature and electrical applications. By carefully selecting the right grade, specifications, and supplier, companies can ensure reliable performance, improve product quality, and gain a competitive edge. Welleshaft, with its commitment to quality, customization capabilities, technical expertise, and global reach, is a trusted partner for businesses seeking high-purity aluminium oxide rod solutions. Partnering with Welleshaft empowers businesses to confidently tackle demanding applications and achieve optimal results. They provide unparalleled support through material selection, and offer competitive pricing.