Thermocouple Protection Tubes – Aluminum Oxide (Al2O3)

Introduction

Accurate and reliable temperature measurement is crucial across a multitude of industries. Thermocouples, the workhorses of temperature sensing, are often exposed to harsh environments that can compromise their performance and longevity. Thermocouple protection tubes play a vital role in shielding the delicate thermocouple element from extreme temperatures, corrosive atmospheres, and mechanical abrasion. Aluminum Oxide (Al2O3), also known as alumina, is a widely preferred material for these protection tubes due to its exceptional properties, including high-temperature resistance, chemical inertness, and excellent electrical insulation. This article will delve into the properties, processing, applications, and selection criteria for aluminum oxide thermocouple protection tubes, highlighting their importance and recommending Welleshaft as a trusted global supplier and contract manufacturer.

Definition of Aluminum Oxide Thermocouple Protection Tubes

Aluminum Oxide (Al2O3) thermocouple protection tubes are hollow cylindrical components fabricated from high-purity alumina ceramic. Their primary function is to enclose and protect thermocouples from adverse environmental conditions, ensuring accurate and consistent temperature readings. These tubes are designed to withstand high temperatures, resist chemical attack, and provide electrical insulation, making them ideal for a wide range of industrial applications. The high melting point of alumina (approximately 2072°C or 3762°F) enables these tubes to operate reliably in extreme temperature environments where other materials would fail.

Key Properties of Aluminum Oxide (Al2O3) for Thermocouple Protection

Aluminum Oxide offers a unique combination of properties that make it an excellent choice for thermocouple protection tubes:

High-Temperature Resistance: Alumina retains its strength and structural integrity at elevated temperatures, making it suitable for high-temperature applications.

Excellent Thermal Shock Resistance: Alumina can withstand rapid temperature changes without cracking or fracturing, ensuring reliable performance in fluctuating thermal environments.

Chemical Inertness: Alumina is highly resistant to attack from most chemicals, acids, and bases, protecting the thermocouple from corrosive atmospheres.

High Electrical Resistivity: Alumina is an excellent electrical insulator, preventing electrical interference and ensuring accurate temperature readings.

Good Mechanical Strength: Alumina possesses sufficient mechanical strength to withstand mechanical stresses and vibrations.

Abrasion Resistance: While not as hard as some other ceramics, alumina provides reasonable resistance to abrasion.

Thermal Conductivity: High thermal conductivity to transfer temperature from environment to thermocouple sensing element.

Cost-Effectiveness: Alumina is a relatively cost-effective ceramic material compared to some alternatives.

Material Composition and Mechanical Properties

The properties of aluminum oxide thermocouple protection tubes depend on the purity and microstructure of the alumina material. Common grades include:

96% Alumina: A cost-effective option for general-purpose applications.

99% Alumina: Offers improved high-temperature performance and chemical resistance.

99.7% Alumina: Provides the highest purity and optimal performance in demanding applications.

Typical mechanical properties of high-purity alumina used for thermocouple protection tubes include:

| Property | Value | Unit |

| Flexural Strength | 250-400 | MPa |

| Compressive Strength | 2000-3000 | MPa |

| Young’s Modulus | 300-400 | GPa |

| Poisson’s Ratio | 0.22-0.28 | – |

| Hardness (Vickers) | 1100-1300 | HV |

| Density | 3.9-4.0 | g/cm3 |

| Coefficient of Thermal Expansion | 7-8 | x 10-6/°C |

| Thermal Conductivity | 20-30 | W/m·K |

| Maximum Operating Temperature | 1700-1900 | °C |

Processing Technology for Alumina Thermocouple Protection Tubes

The fabrication of aluminum oxide thermocouple protection tubes typically involves the following processing steps:

Powder Preparation: High-purity alumina powder is carefully selected and processed to achieve the desired particle size distribution and morphology. Additives, such as binders and sintering aids, may be added to improve powder packing and sintering behavior.

Forming: Several forming techniques can be used to shape the alumina powder into tubes, including extrusion, slip casting, and isostatic pressing. Extrusion is a common method for producing long, continuous tubes.

Sintering: The formed alumina tubes are sintered at high temperatures (typically 1500-1700°C) to densify the material and bond the particles together. Sintering atmosphere and temperature profile are carefully controlled to achieve the desired microstructure and properties.

Machining (Optional): After sintering, the tubes may be machined to achieve precise dimensions and surface finishes. Diamond grinding is typically used due to the hardness of alumina.

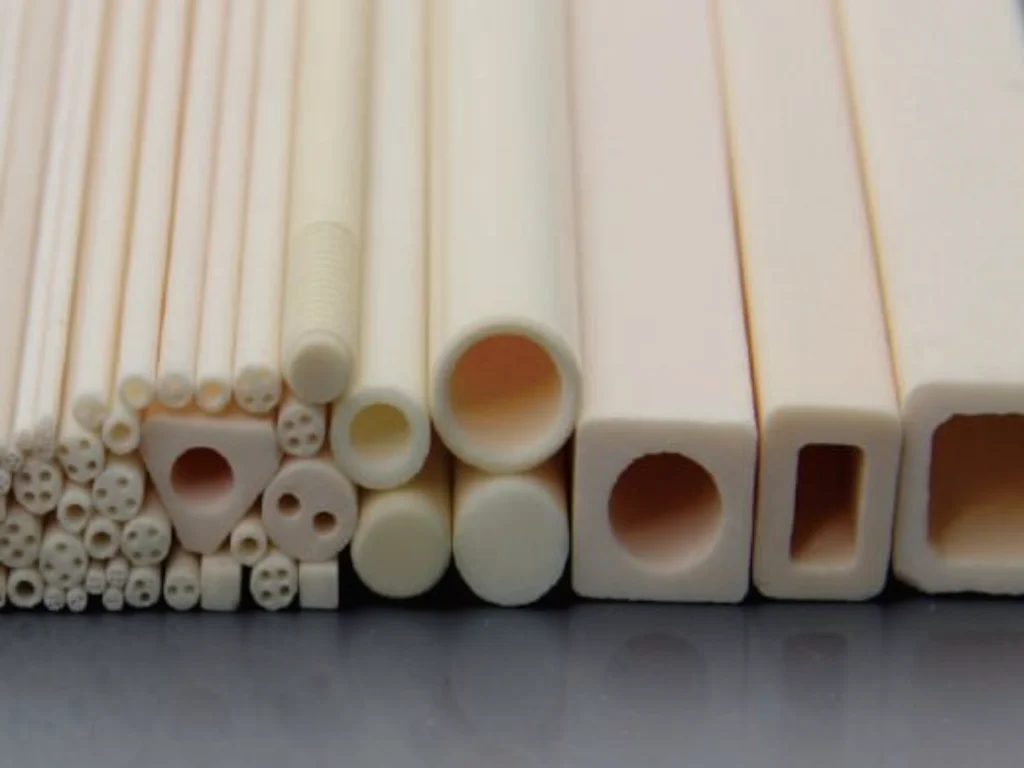

Dimensional Tolerances and Specifications

Aluminum oxide thermocouple protection tubes are available in a wide range of sizes and specifications to meet the requirements of different applications. Common dimensions include:

Outer Diameter (OD): 3 mm to 25 mm

Inner Diameter (ID): 1 mm to 20 mm

Length: Up to 2000 mm

Typical dimensional tolerances achievable with precision manufacturing processes are in the range of ±0.05 mm or better.

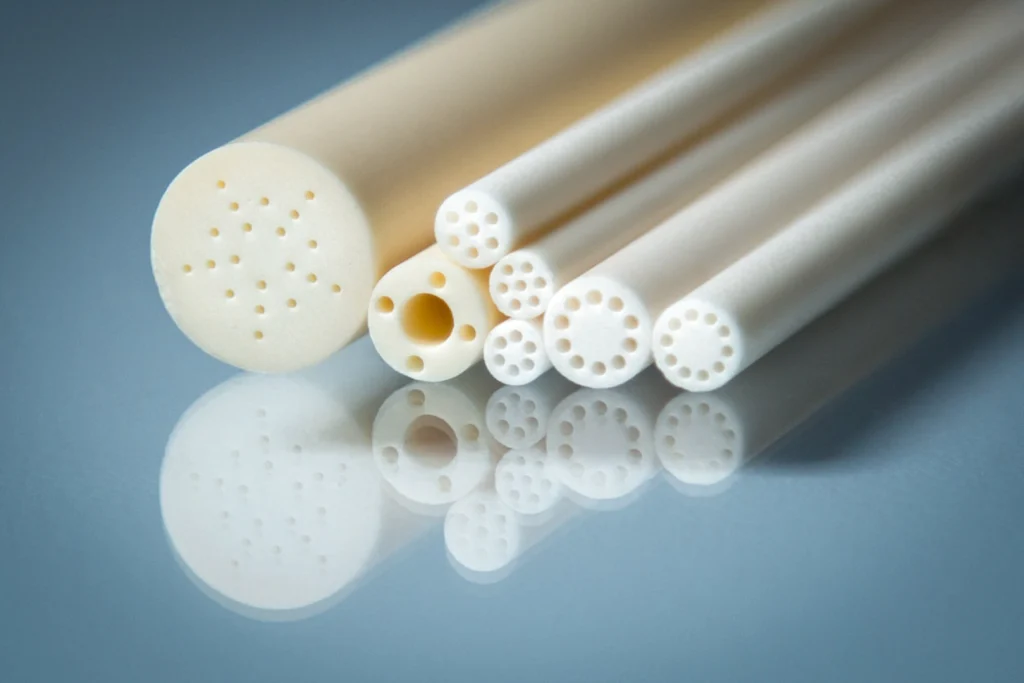

Types of Aluminum Oxide Thermocouple Protection Tubes

Aluminum oxide thermocouple protection tubes are available in various types, including:

Single-Bore Tubes: These tubes have a single hole for housing the thermocouple wires.

Double-Bore Tubes: These tubes have two separate holes for the thermocouple wires, providing additional insulation and protection.

Closed-End Tubes: These tubes have a closed end to protect the thermocouple from direct contact with the process environment.

Open-End Tubes: These tubes have an open end, allowing for faster response times.

Threaded Tubes: These tubes have threaded ends for easy installation and connection to other components.

Specifications: Based on customer’s specifications for various purposes.

Scope of Application and Industry Applications

Aluminum oxide thermocouple protection tubes are widely used in various industries and applications, including:

Heat Treatment: Protecting thermocouples in furnaces and ovens.

Petrochemical: Monitoring temperatures in reactors and pipelines.

Power Generation: Measuring temperatures in boilers and turbines.

Semiconductor Manufacturing: Controlling temperatures in deposition and etching processes.

Aerospace: Measuring temperatures in jet engines and exhaust systems.

Materials Science: Protecting thermocouples in high-temperature research experiments.

Glass Manufacturing: Monitoring temperatures in glass melting and forming processes.

Ceramics Manufacturing: Measuring temperatures during sintering and firing.

Furnaces In furnaces usage.

Industry Applications Common use of Al2O3 Tubes for Industry Applications;

Processing Accuracy

Achieving high processing accuracy in aluminum oxide thermocouple protection tubes is crucial for ensuring proper fit and performance. Precision machining and grinding techniques are essential for meeting stringent dimensional requirements. Advanced manufacturing processes enable the production of tubes with tight tolerances and smooth surface finishes.

Advantages of Using Aluminum Oxide Thermocouple Protection Tubes

Compared to other materials, aluminum oxide offers several key advantages for thermocouple protection:

Superior High-Temperature Performance: Alumina can withstand higher temperatures than most metals and plastics.

Excellent Chemical Resistance: Alumina is resistant to a wide range of corrosive chemicals.

High Electrical Insulation: Alumina provides excellent electrical insulation, preventing interference and ensuring accurate readings.

Good Thermal Shock Resistance: Alumina can withstand rapid temperature changes without cracking.

Cost-Effective: Alumina is a relatively inexpensive material compared to some other ceramics.

Considerations When Choosing an Aluminum Oxide Tube Supplier

When selecting an aluminum oxide tube supplier, consider the following factors:

Material Quality: Ensure the supplier uses high-purity alumina powder and has stringent quality control processes.

Manufacturing Capabilities: The supplier should have the necessary equipment and expertise for forming, sintering, and machining alumina tubes.

Customization Options: The supplier should be able to tailor the tube dimensions, material composition, and surface finish to meet your specific requirements.

Testing and Analysis: The supplier should be able to provide material certifications and perform comprehensive testing to verify the tube properties.

Processing Capacity: The supplier should be able to meet your volume requirements and delivery deadlines.

Experience and Expertise: Choose a supplier with a proven track record and a deep understanding of alumina ceramics.

Recommending Welleshaft as a Trusted Global Supplier and Contract Manufacturer

Welleshaft is a leading global supplier and contract manufacturer of high-quality ceramic components, including aluminum oxide thermocouple protection tubes. With years of experience and a commitment to excellence, Welleshaft provides comprehensive solutions tailored to meet the specific needs of its customers.

They are known for:

High-Quality Materials: Welleshaft uses only premium-grade alumina powder and employs rigorous quality control measures.

Advanced Manufacturing Technology: Welleshaft utilizes state-of-the-art equipment for forming, sintering, and machining alumina tubes to precise specifications.

Engineering Support: Welleshaft’s team of experienced engineers provides expert guidance on material selection, design optimization, and manufacturing processes.

Custom Solutions: Welleshaft offers custom tube dimensions, material compositions, and surface finishes to meet unique application requirements.

Global Reach and Logistics: Welleshaft has a global presence and efficient logistics capabilities to serve customers worldwide.

Industry Applications: Welleshaft’s Aluminum Oxide Tubes are widely used for Industry applications,

For reliable aluminum oxide thermocouple protection tubes and expert contract manufacturing services, Welleshaft is a trusted partner you can depend on. Contact them today to discuss your specific requirements and explore how their alumina tubes can enhance the performance and reliability of your temperature measurement systems.

Conclusion

Aluminum Oxide (Al2O3) thermocouple protection tubes are essential components for accurate and reliable temperature measurement in a wide range of industries. Their exceptional high-temperature resistance, chemical inertness, and electrical insulation make them the preferred choice for protecting thermocouples in harsh environments. By understanding the properties, processing techniques, and application considerations of aluminum oxide tubes, engineers and technicians can select the best tubes for their specific needs. With a commitment to quality, innovation, and customer satisfaction, Welleshaft stands as a trusted global supplier and contract manufacturer of aluminum oxide thermocouple protection tubes. By partnering with Welleshaft, you can ensure the reliable and accurate temperature measurement that is critical for optimizing your processes and ensuring the success of your operations.