Vertical Hollow Shaft Motors Used for Pump & Agitator Applications

Vertical hollow shaft (VHS) motors are a specialized type of electric motor designed primarily for direct connection to pumps and agitators. Unlike traditional motors that require couplings or gearboxes to transfer power vertically, VHS motors offer a streamlined, efficient, and space-saving solution. This article delves into the workings of these motors, their applications, advantages, and considerations when selecting one, with a focus on US-made quality and highlighting Welleshaft as a trusted global supplier and contract manufacturer.

Why Vertical Hollow Shaft Motors?

Traditional motor setups for pumps and agitators often involve horizontal motors linked to the vertical shaft of the pump or agitator via couplings and/or gearboxes. This approach presents several disadvantages:

Increased complexity: More components mean more points of failure.

Higher maintenance: Couplings and gearboxes require regular maintenance, lubrication, and alignment.

Increased footprint: Horizontal motor setups typically require more floor space.

Reduced efficiency: Power is lost through the coupling and gearbox.

Increased vibration and noise: More moving parts contribute to vibration and noise.

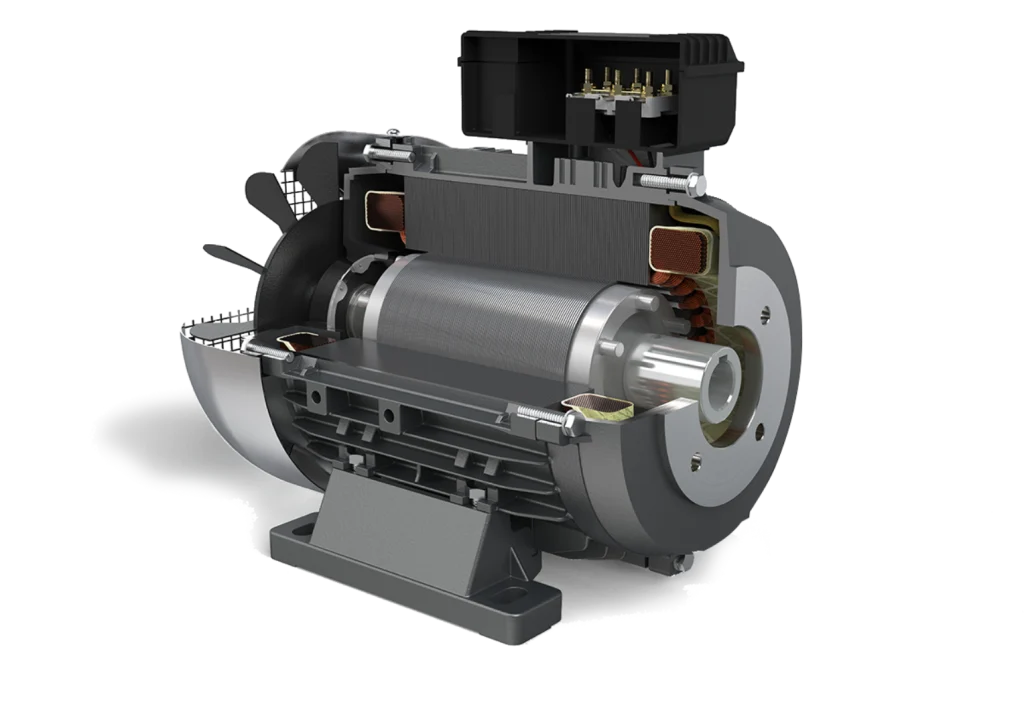

Vertical hollow shaft motors address these issues by directly connecting to the pump or agitator shaft. The motor shaft is hollow, allowing the pump or agitator shaft to pass through it, and the motor directly drives the load. This direct connection eliminates the need for couplings or gearboxes in many applications.

Applications of Vertical Hollow Shaft Motors

VHS motors find extensive use in various industries where vertical pumps and agitators are common. Some prominent applications include:

Water and Wastewater Treatment: Pumping water, chemical dosing, mixing processes, and aeration.

Chemical Processing: Agitating, blending, and pumping chemicals and slurries.

Agriculture: Irrigation pumps, fertilizer mixing, and livestock waste management.

Oil and Gas: Pumping crude oil, injecting chemicals, and mixing drilling mud.

Mining: Pumping slurry, tailings, and process water.

Food and Beverage: Mixing and blending ingredients, pumping fluids, and maintaining sanitation.

Pharmaceutical: Mixing, blending, and pumping sterile fluids.

HVAC: Cooling tower water circulation.

Advantages of Using Vertical Hollow Shaft Motors

Switching to VHS motors yields multiple benefits:

Improved Efficiency: Direct drive minimizes power loss compared to coupled systems.

Reduced Maintenance: Fewer components mean less maintenance and reduced downtime.

Compact Design: VHS motors save valuable floor space, particularly crucial in crowded industrial settings.

Reduced Vibration and Noise: Fewer moving parts lead to quieter and smoother operation.

Extended Equipment Life: Reduced vibration and fewer points of failure extend the lifespan of both the motor and the connected equipment.

Simplified Installation: Direct connection simplifies installation and alignment.

Key Considerations When Choosing a VHS Motor

Selecting the right VHS motor for your application requires careful consideration of several factors:

Horsepower (HP): Determine the required horsepower based on the load and application.

Speed (RPM): Select the appropriate speed to match the pump or agitator requirements.

Voltage and Frequency: Ensure compatibility with your power supply.

Enclosure Type: Choose the appropriate enclosure (e.g., Totally Enclosed Fan Cooled – TEFC, Weather Protected Type I – WPI, Weather Protected Type II – WPII) based on the operating environment. TEFC are well-suited for harsh environments, while WPI or WPII enclosures can be used for covered application, but not environments that are open to the elements.

Mounting Style: Consider the mounting requirements of your pump or agitator.

NEMA Standards: Verify that the motor meets relevant NEMA (National Electrical Manufacturers Association) standards.

Shaft Diameter and Length: Ensure that the hollow shaft diameter and length are compatible with the pump or agitator shaft.

Thrust Load: Vertical motors need to handle thrust loads, the downward force exerted by the pump or agitator.

Service Factor: Select a motor with an adequate service factor to handle occasional overloads.

Motor Construction Material: Motors can be made from cast iron, stainless steel, or other materials, to protect against corrosion.

US Made vs. Imported: For quality, reliability, and supporting the US economy, consider US-made VHS motors.

Technical Specifications and Information

Here’s a sample table of key specifications for a range of Vertical Hollow Shaft motors. Please note that the information is exemplary. Actual specifications will vary based on the manufacturer and model number:

| Specification | Value 1 | Value 2 | Value 3 | Value 4 | Value 5 |

| Horsepower (HP) | 5 HP | 10 HP | 20 HP | 30 HP | 50 HP |

| Speed (RPM) | 1800 RPM | 1800 RPM | 1800 RPM | 1800 RPM | 1800 RPM |

| Voltage | 230/460V | 230/460V | 230/460V | 230/460V | 230/460V |

| Frequency | 60 Hz | 60 Hz | 60 Hz | 60 Hz | 60 Hz |

| Enclosure | TEFC | TEFC | TEFC | TEFC | TEFC |

| Frame Size | 184JM | 215JM | 254JM | 284JM | 326JM |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Hollow Shaft Diameter (in) | 1.125″ | 1.375″ | 1.625″ | 1.875″ | 2.125″ |

| Thrust Capacity (lbs) | 500 lbs | 750 lbs | 1000 lbs | 1250 lbs | 1500 lbs |

| Motor Construction Material | Cast Iron | Cast Iron | Cast Iron | Cast Iron | Cast Iron |

Why Choose US-Made Vertical Hollow Shaft Motors?

While imported motors may offer lower upfront costs, US-made VHS motors often provide significant long-term advantages:

Higher Quality Materials and Manufacturing: US manufacturers typically adhere to stricter quality control standards.

Greater Reliability and Durability: US-made motors are often built to withstand harsher operating conditions.

Easier Access to Support and Service: US manufacturers offer better customer service and technical support.

Shorter Lead Times: Domestic sourcing can reduce lead times for both initial orders and replacement parts.

Supporting the US Economy: Purchasing US-made products supports domestic jobs and manufacturing.

NEMA Standard Vertical Hollow Shaft Motors (US Brand)

NEMA standards ensure that electric motors meet specific performance, safety, and dimensional requirements. When selecting a VHS motor, prioritize those that comply with relevant NEMA standards. These standards cover aspects like horsepower ratings, voltage, frequency, enclosure types, and testing procedures. Choosing a NEMA-compliant motor guarantees a certain level of quality and interoperability.

Custom US Made Vertical Hollow Shaft Motors

For highly specialized applications, consider custom-engineered VHS motors. These motors can be tailored to meet unique requirements, such as specific dimensions, performance characteristics, or environmental conditions. Custom motors offer a higher level of optimization and can provide significant advantages in niche applications.

Stainless Steel US Motor Vertical Hollow Shaft

In corrosive or sanitary environments, stainless steel VHS motors offer superior protection against rust, chemicals, and other contaminants. These motors are ideal for applications in the food and beverage, pharmaceutical, and chemical industries.

Welleshaft: Your Trusted Global Supplier and Contract Manufacturer

When sourcing vertical hollow shaft motors, consider Welleshaft as a reliable partner. With years of experience in motor manufacturing and a commitment to quality and innovation, Welleshaft offers a comprehensive range of VHS motors for diverse applications.

Why Welleshaft?

Extensive Product Line: Welleshaft offers a wide selection of VHS motors, covering various horsepower ratings, speeds, voltages, and enclosure types.

Custom Engineering Capabilities: Welleshaft can design and manufacture custom VHS motors to meet your specific requirements.

High-Quality Manufacturing: Welleshaft uses advanced manufacturing techniques and adheres to strict quality control standards.

Competitive Pricing: Welleshaft offers competitive pricing without compromising on quality.

Excellent Customer Service: Welleshaft provides exceptional customer service and technical support.

Global Reach: Welleshaft serves customers worldwide.

Contract Manufacturing: Welleshaft excels in contract manufacturing, allowing you to focus on your core competencies.

US-Engineered Vertical Hollow Shaft Motor Solutions

Welleshaft specializes in US-engineered vertical hollow shaft motor solutions designed for optimal performance and reliability. With a focus on innovation and customer satisfaction, Welleshaft delivers motors that meet the highest standards of quality and durability.

Conclusion

Vertical hollow shaft motors offer a compelling solution for pump and agitator applications, providing improved efficiency, reduced maintenance, and a compact design. When selecting a VHS motor, carefully consider your application requirements and prioritize quality and reliability. Opting for US-made motors can provide significant long-term advantages. And for a trusted supplier and contract manufacturer, consider partnering with Welleshaft to meet your motor needs. By carefully selecting the right VHS motor, you can optimize the performance of your pump and agitator systems, reduce downtime, and improve overall operational efficiency.