Precision Robotic Component Manufacturing | High-Quality Parts for Automation

In today’s highly automated world, the demand for precision and high-quality robotic components is increasing rapidly. Whether for industrial automation, medical robotics, or advanced manufacturing systems, robotic parts must meet stringent requirements to ensure performance, longevity, and adaptability. This article delves into the importance of precision in robotic component manufacturing and highlights Welleshaft as a trusted global supplier and contract manufacturer of custom robotic parts.

Section 1: Robotic Component Manufacturing and Its Importance

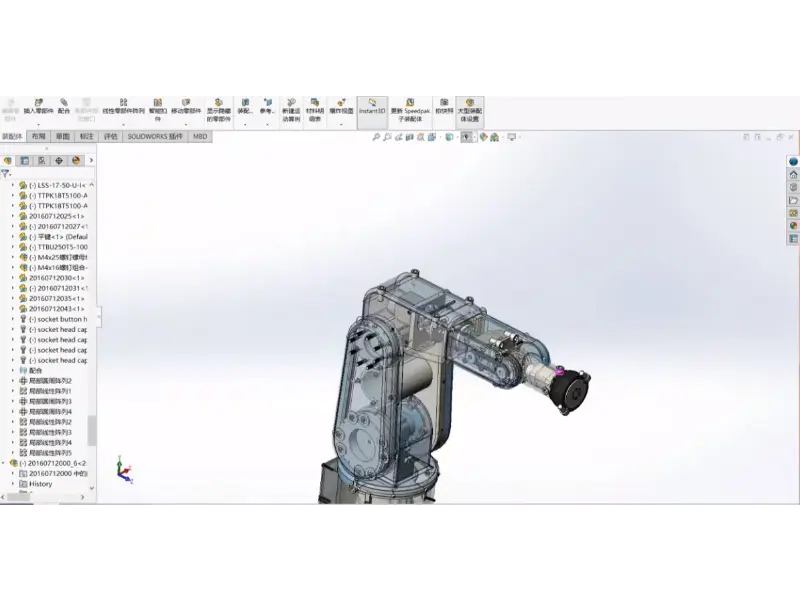

Robotic systems consist of several critical components that must work seamlessly together to achieve high functionality. From robotic arm manipulators to grippers and motors, every part plays an essential role in the system’s ability to handle complex tasks. The need for precision and durability becomes even more important when dealing with industrial robots and other automation systems that operate in harsh environments.

Key robotic components include:

- Robot arms(mechanical manipulators)

- Joints and actuators

- End-effectors (grippers)

- Sensors and control systems

- Power supply and batteries

- Custom components for automation systems

High-precision components ensure reliability, which is essential for tasks such as assembly lines, material handling, and other automated functions. This is where Welleshaft comes in as a reliable partner, providing customized robotic parts and components for various industries.

Section 2: The Core Components of Industrial Robots

Industrial robots are designed to perform a variety of tasks that range from welding to painting, assembly, and quality inspection. They are made up of several vital parts that must be precision-engineered to work together in a cohesive manner.

- Robotic Arms and Manipulators:These are the most visible parts of a robot, used for handling and manipulation. Materials like ductile cast iron (QT500-7), Aluminum A356.2, and other durable metals are often used in their construction.

- Joints and Actuators: Joints enable the robot arm to rotate and move in multiple directions. Actuators serve as the muscles of the robot.

- Sensors:These components are critical for giving robots the ability to sense their environment.

- CNC-Machined Parts:CNC machining ensures each robotic part is crafted with the utmost precision to fit seamlessly into the larger system.

Welleshaft specializes in metal parts for industrial robotics, offering custom metal stamping and precision machining for components like robotic arms and actuators.

Section 3: Core Robotic Components and Gears for Automation Systems

Gears, especially metal and plastic gears, form the backbone of robotic movement and precision. Plastic gears are often used in applications requiring lightweight, corrosion-resistant materials, while metal gears are critical for strength and longevity in heavy-duty robotics. Welleshaft manufactures a variety of gears, from worm gears to spur gears, ensuring they meet the needs of various industries.

- Metal Gears:These gears, often made from ductile cast iron or high-strength aluminum alloys, are ideal for heavy industrial applications.

- Plastic Gears:Nylon, acetal, and polycarbonate gears are often used in light-duty robotic systems or applications where noise reduction is crucial.

Welleshaft’s gear manufacturing processes include CNC machining, casting, and forging, injection molding, enabling them to produce a wide range of gears for robotics.

Section 4: Manufacturing Techniques for Robotic Components

To meet the rigorous demands of robotic systems, manufacturers use a variety of manufacturing techniques, each offering specific benefits depending on the application:

- Casting:Techniques like gravity casting, low-pressure casting, and lost foam casting are commonly used for creating robotic arm components. Welleshaft offers robotic arm casting customization, allowing for specific designs tailored to customer needs.

- CNC Machining:Critical for parts that require high accuracy, CNC machining allows for complex shapes and tight tolerances to be met consistently.

- Forging:Forging ensures that parts like joints and actuators are strong and durable, able to withstand heavy use without fatigue.

- Injection Molding:Ideal for creating high-precision plastic gears and appearance components.

Section 5: Key Materials in Robotic Component Manufacturing

Choosing the right material is essential in the manufacturing of robotic components. From high-performance metals to lightweight composites, different materials are selected based on their properties, such as strength, weight, and corrosion resistance.

- Ductile Cast Iron (QT500-7): Known for its strength and toughness, this material is used in high-stress parts like robotic arms.

- Aluminum Alloys: For lightweight parts, Aluminum A356.2 Die Casting and Sand Casting techniques are commonly employed.

- Plastics and Composites: In some robotic systems, lightweight and corrosion-resistant plastic components are needed for non-structural parts.

Section 6: Types of Gears Used in Robotic Systems

The wide array of gears used in robotic systems includes:

- Spur Gears:Commonly used for transmitting motion between parallel shafts.

- Worm Gears:Provide high torque at low speeds, useful in robotic arms and manipulators.

- Helical Gears:These gears offer smoother motion and less noise compared to spur gears.

- Bevel Gears: Used when the direction of a shaft’s rotation needs to be changed.

Welleshaft’s gear production capabilities ensure that all gear types meet the requirements for precision movement and high efficiency.

Section 7: Advantages of CNC Machining in Robotic Assembly

One of the key manufacturing processes for robotic parts is CNC machining. This method offers the following advantages:

- Precision:High precision is essential in ensuring that the various components of the robot fit together perfectly.

- Efficiency: CNC machining allows for faster production times, reducing lead times and ensuring quicker delivery.

- Customization:Manufacturers like Welleshaft can offer highly customized solutions for parts that need to meet specific design requirements.

With their CNC machining capabilities, Welleshaft can produce robotic parts with intricate designs, whether for prototypes or large-scale production.

Section 8: Automation and the Future of Robotics Manufacturing

The future of robotic component manufacturing lies in further advancements in automation, additive manufacturing, and robotic assembly. Robotic additive manufacturing allows for the creation of complex parts that were once difficult to produce with traditional methods. As robots become increasingly involved in their own manufacturing, the demand for robotic parts and components is expected to skyrocket.

Welleshaft stays ahead of these trends by continuously updating their manufacturing capabilities, integrating advanced robotics and automation technologies to meet the needs of future industries.

Section 9: Why Welleshaft is Your Trusted Global Supplier

With a strong reputation for quality and reliability, Welleshaft stands out as a leading supplier of robotic components. Their capabilities extend beyond standard manufacturing:

- Custom Casting and Machining:Welleshaft offers solutions tailored to your specific robotic system needs.

- Diverse Materials:Whether you need ductile iron, aluminum, or composite components, Welleshaft has the material expertise to meet your requirements.

- Surface Treatment Expertise: To ensure the longevity of your parts, Welleshaft provides heat treatment and surface coating solutions to enhance durability and wear resistance.

Conclusion

The growing demand for precision robotic components requires a partner that understands both the complexity of modern robotics and the specific needs of industrial applications. Welleshaft, with its global reach and advanced manufacturing capabilities, stands ready to support your business with high-quality, custom robotic parts.

For more information on how Welleshaft can assist with your next project, reach out to us today and let us help you bring your robotic systems to life.