Stainless Steel Injection Molding | Precision Components for Every Industry

Stainless steel injection molding is a cutting-edge manufacturing process that combines the versatility of plastic injection molding with the durability and strength of stainless steel. This technique is becoming increasingly popular across various industries due to its ability to produce complex, high-precision components that meet stringent performance requirements. In this article, we’ll explore the benefits of stainless steel injection molding, its applications, and why Welleshaft is your trusted global supplier and contract manufacturer for these high-quality components.

Section 1: What is Stainless Steel Injection Molding?

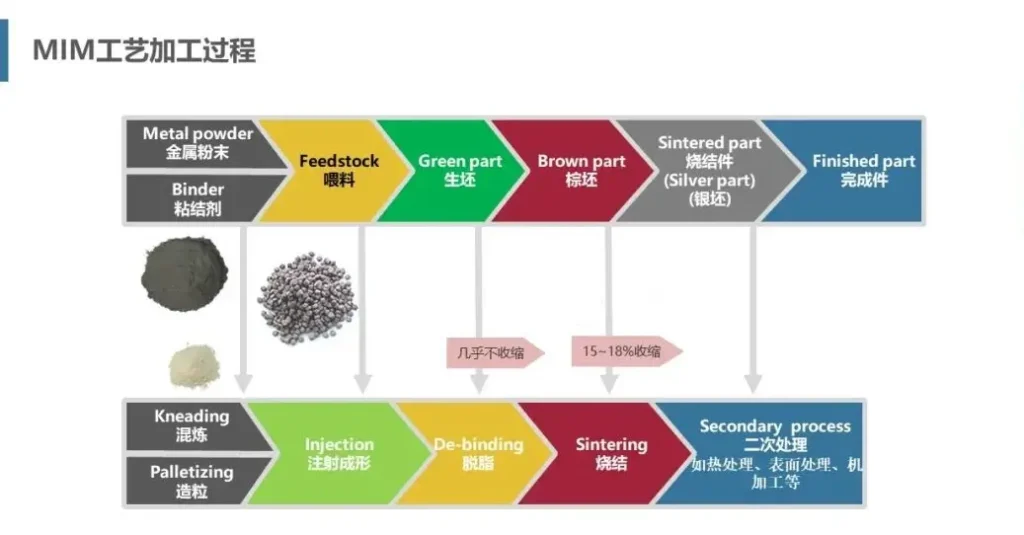

Stainless steel injection molding, also known as Metal Injection Molding (MIM) for stainless steel, is a process that involves mixing finely powdered stainless steel with a binder material to create a feedstock. This feedstock is then injected into a mold cavity using an injection molding machine, forming intricate shapes with high precision. Once molded, the binder is removed, and the stainless steel part is sintered at high temperatures to achieve its final density and mechanical properties.

Section 2: The Process of Stainless Steel Injection Molding

Feedstock Preparation: The process begins by blending stainless steel powder with a binder to create a homogeneous mixture, known as feedstock.

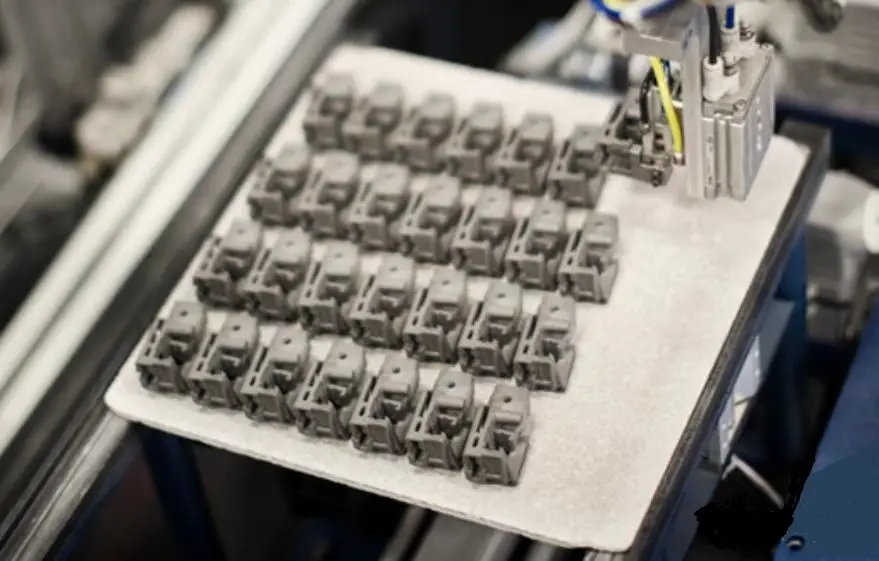

Injection Molding: The feedstock is then heated and injected into a mold cavity using an injection molding machine, forming the desired shape.

Debinding: The molded part undergoes a debinding process to remove the binder material, leaving behind a “green part” made of stainless steel powder.

Sintering: The green part is sintered at high temperatures, causing the stainless steel particles to fuse together, resulting in a dense and strong final component.

Post-Processing: Depending on the application, additional processes such as machining, polishing, or coating may be applied to achieve the desired finish.

Section 3: Advantages of Stainless Steel Injection Molding

1. Complex Geometries

One of the primary advantages of stainless steel injection molding is its ability to produce complex shapes that would be difficult or impossible to achieve with traditional manufacturing methods. The MIM process allows for the creation of intricate components with fine details, thin walls, and undercuts.

2. High Precision and Consistency

Stainless steel injection molding offers exceptional dimensional accuracy and repeatability, making it ideal for producing large volumes of parts with consistent quality. This is particularly important in industries where precision is critical, such as medical devices, aerospace, and automotive.

3. Material Strength and Durability

Stainless steel is known for its excellent mechanical properties, including high tensile strength, corrosion resistance, and wear resistance. Components produced through stainless steel injection molding inherit these properties, making them suitable for demanding applications.

4. Cost-Effectiveness

While the initial tooling costs for stainless steel injection molding can be high, the process becomes cost-effective when producing large quantities of parts. The ability to produce complex components in a single step reduces the need for additional machining or assembly, resulting in lower overall production costs.

5. Material Versatility

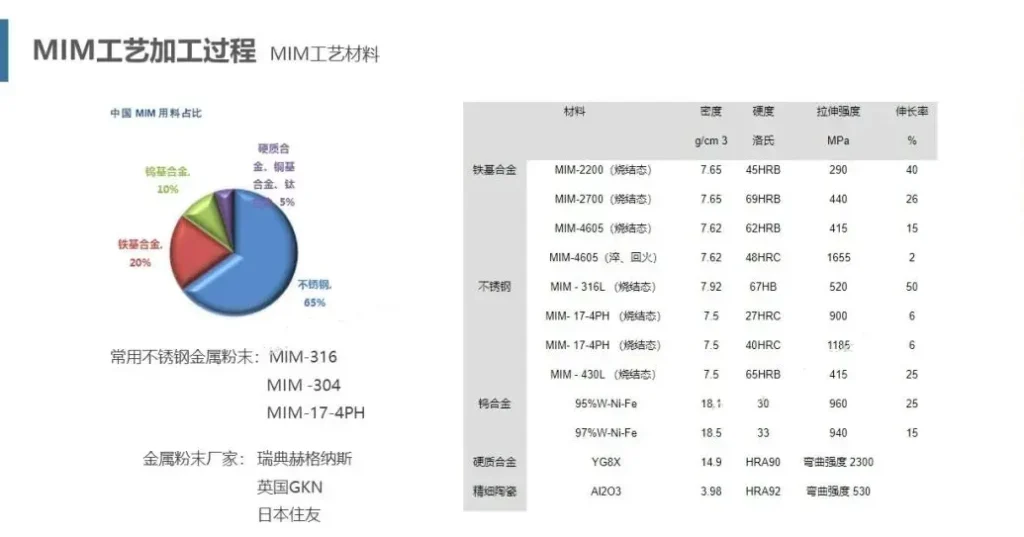

Stainless steel injection molding can be used with various grades of stainless steel, allowing manufacturers to select the best material for the specific application. Common grades include 316L, 17-4PH, and 304, each offering different properties such as corrosion resistance, hardness, and machinability.

For more information on high-quality Stainless steel MIM Manufacturer and to find the perfect solution for your application, please contact us.

Jinan Welle Metal Products Co., Ltd (Welleshaft)

Website: www.welleshaft.com

Email: [email protected]

Phone: +86-156-5017-9596

Explore our range of durable and reliable Stainless steel MIM Parts today!

Section 4: Applications of Stainless Steel Injection Molding

Stainless steel injection molding is utilized across a wide range of industries due to its versatility and the high-quality components it produces. Key applications include:

1. Medical Devices

MIM stainless steel is commonly used in the medical industry to manufacture surgical instruments, orthopedic implants, and dental devices. The process allows for the production of biocompatible, high-precision components that meet strict regulatory standards.

2. Automotive Industry

In the automotive sector, stainless steel injection molding is used to produce complex parts such as fuel injector components, turbocharger assemblies, and sensor housings. The process enables the creation of lightweight, durable parts that contribute to overall vehicle performance.

3. Aerospace Industry

Aerospace applications require components that can withstand extreme conditions, and stainless steel injection molding is ideal for producing parts such as turbine blades, fasteners, and structural components. The high strength and corrosion resistance of stainless steel ensure long-lasting performance in challenging environments.

4. Consumer Electronics

The miniaturization of electronic devices demands precise, durable components, making stainless steel injection molding a preferred choice for manufacturing connectors, housings, and other intricate parts in consumer electronics.

5. Industrial and Defense Applications

Stainless steel injection molding is also used in industrial and defense applications to produce components like valves, fittings, and firearm parts. The process offers the ability to produce high-strength, corrosion-resistant parts with complex geometries.

Section 6: Why Choose Welleshaft for Stainless Steel Injection Molding?

1. Trusted Global Supplier

Welleshaft is a leading global supplier and contract manufacturer of stainless steel injection molding components. With a strong presence in key markets worldwide, including the USA, Europe, China, and India, we provide our clients with top-quality products and reliable service.

2. Expertise and Experience

Our team of skilled engineers and technicians has extensive experience in stainless steel injection molding. We leverage advanced MIM technology and state-of-the-art equipment to deliver high-precision components that meet the most demanding specifications.

3. Comprehensive Services

At Welleshaft, we offer a full range of services, from design and prototyping to full-scale production and post-processing. Our commitment to quality and customer satisfaction ensures that we deliver components that exceed expectations.

4. Cost-Effective Solutions

We understand the importance of cost efficiency in manufacturing. Our stainless steel injection molding process is designed to minimize waste, reduce production costs, and deliver high-quality components at competitive prices.

5. Global Support

With manufacturing facilities and support teams in major regions worldwide, Welleshaft provides localized service and expertise to meet the needs of our global clients. Whether you require components for the USA, Europe, China, or India, we have the resources to deliver.

Conclusion

Stainless steel injection molding is an innovative and efficient method for producing high-precision components across various industries. With its ability to create complex shapes, maintain material integrity, and deliver cost-effective solutions, this process is becoming the go-to choice for manufacturers worldwide.

Welleshaft stands out as a trusted global supplier and contract manufacturer, offering exceptional expertise, advanced technology, and a commitment to quality. Whether you need components for medical devices, automotive, aerospace, or consumer electronics, Welleshaft is your partner for stainless steel injection molding solutions.

For more information or to discuss your specific requirements, visit Welleshaft or contact us directly. We look forward to partnering with you on your next project.