Top Quality Stud Rods – Reliable & Durable Solutions

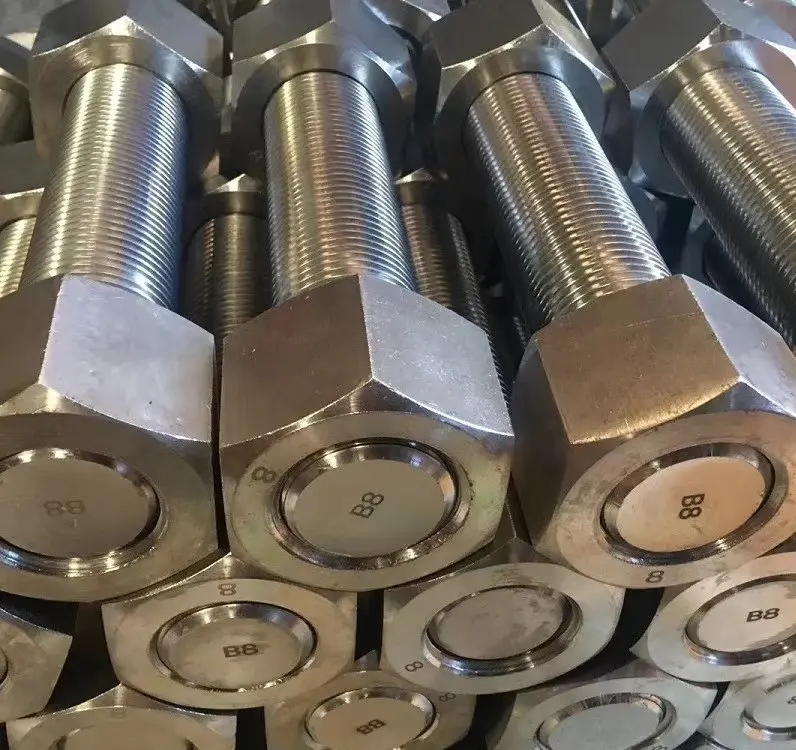

When it comes to choosing the right components for industrial and construction applications, the quality of stud rods cannot be compromised. Stud rods, also known as threaded rods or stud threaded rods, are essential for creating secure and reliable connections in a variety of settings. In this article, we will explore the key features of top-quality stud rods, their applications, and why Welleshaft is your trusted global supplier and contract manufacturer for these high-performance products.

What Are Stud Rods?

Stud rods are long, cylindrical rods with threads running along their entire length. They are used to create strong, durable connections between components in machinery, construction, and other applications. The primary difference between stud rods and standard bolts is that stud rods are fully threaded, which allows them to be used in a wider range of applications.

Types of Stud Rods

Fully Threaded Studs

Fully threaded studs, also known as all thread studs, have threads running the entire length of the rod. This design makes them versatile and suitable for various applications where the length of the rod needs to be adjustable. Fully threaded studs are commonly used in construction and heavy machinery.

Partially Threaded Rods

Partially threaded rods have threads only along a portion of their length. These are typically used in applications where one end of the rod needs to be unthreaded for easier installation or to accommodate specific components. Partially threaded rods are often employed in automotive and structural applications.

Internally Threaded Rods & Studs

Internally threaded rods and studs have threads on the inside of the rod, which allows them to be used in conjunction with external bolts or screws. These are often used in applications where a secure connection is required without the need for additional fasteners.

Stud Thread Rods & Studs

Stud thread rods are fully threaded rods used in various applications, providing strong and secure fastening. They are available in different sizes and materials, making them suitable for a wide range of uses.

For more information on high-quality Stud Rods and to find the perfect solution for your application, please contact us.

Jinan Welle Metal Products Co., Ltd (Welleshaft)

Website: www.welleshaft.com

Email: [email protected]

Phone: +86-156-5017-9596

Explore our range of durable and reliable Threaded&Stud Rods today!

Key Specifications and Features

Threaded Rod Sizes

Stud rods come in various sizes and lengths to meet the needs of different applications. Common sizes include M10, 12mm, and 1m lengths. The choice of size depends on the specific requirements of your project.

Threaded Rod Sizes Chart

| Size (Metric) | Size (Inch) | Diameter (mm) | Diameter (inches) | Length (mm) | Length (inches) | Thread Pitch (mm) | Common Uses |

| M6 | 1/4″ | 6 | 0.236 | 100 | 3.94 | 1.0 | Light-duty applications, small machinery |

| M8 | 5/16″ | 8 | 0.315 | 200 | 7.87 | 1.25 | Medium-duty applications, automotive components |

| M10 | 3/8″ | 10 | 0.394 | 300 | 11.81 | 1.5 | Heavy-duty applications, construction |

| M12 | 1/2″ | 12 | 0.472 | 400 | 15.75 | 1.75 | Structural supports, industrial machinery |

| M16 | 5/8″ | 16 | 0.63 | 500 | 19.69 | 2.0 | Large machinery, construction frameworks |

| M20 | 3/4″ | 20 | 0.787 | 600 | 23.62 | 2.5 | Heavy-duty structural components |

| M24 | 1″ | 24 | 0.945 | 700 | 27.56 | 3.0 | Industrial machinery, large structures |

| M30 | 1 1/4″ | 30 | 1.181 | 1000 | 39.37 | 3.5 | High-strength applications, construction |

| M36 | 1 1/2″ | 36 | 1.417 | 1200 | 47.24 | 4.0 | Heavy-duty industrial applications |

| M42 | 1 5/8″ | 42 | 1.654 | 1500 | 59.06 | 4.5 | Large-scale construction, structural supports |

Thread Pitch

1.0 mm: Fine thread pitch for small and medium rods.

1.25 mm: Standard pitch for most general applications.

1.5 mm: Coarse pitch for larger rods and heavy-duty applications.

1.75 mm: Coarse pitch for high-strength and large-diameter rods.

2.0 mm: Very coarse pitch for large and heavy-duty applications.

2.5 mm: Coarse pitch for larger threaded rods.

3.0 mm – 4.5 mm: Very coarse pitch, typically used for heavy-duty industrial applications.

Thread Specifications

UNC (Unified National Coarse): Commonly used for general-purpose fastening.

UNF (Unified National Fine): Provides better tensile strength and thread engagement.

Metric Coarse: Standard metric threading for various applications.<br>

Metric Fine: Similar to UNF, used for applications requiring fine adjustments.

Standards

ASTM: American Society for Testing and Materials.<br>

DIN: German Institute for Standardization.<br>

ISO: International Organization for Standardization.<br>

BS: British Standards.<br>

JIS: Japanese Industrial Standards.

Threaded Rod Length

The length of the stud rod is a crucial factor to consider. Standard lengths range from short rods used in compact applications to longer rods that can be cut to size as needed. Custom lengths are also available to suit specific requirements.

Length Variations

100 mm (3.94 in): Short lengths for small applications.

200 mm (7.87 in): Medium lengths for standard applications.

300 mm (11.81 in): Longer lengths for larger assemblies.

400 mm (15.75 in): Extended lengths for structural supports.

500 mm (19.69 in): Extra-long for extensive applications.

600 mm (23.62 in): Used for very large assemblies.

700 mm (27.56 in): Very long for high-strength applications.

1000 mm (39.37 in): Custom lengths for specialized applications.

1200 mm (47.24 in): Longest standard lengths for heavy-duty needs.

1500 mm (59.06 in): Extra-long for large-scale projects.

Material and Durability

High-quality stud rods are typically made from materials like stainless steel, brass, and carbon steel. Each material offers different benefits, such as corrosion resistance or high tensile strength. Choosing the right material ensures durability and longevity in harsh environments.

Threaded Rod Material & Tensile Strength Chart

| Material | Grade/Specification | Tensile Strength (MPa) | Tensile Strength (psi) | Typical Applications |

| Carbon Steel | ASTM A307 | 240 – 415 MPa | 35,000 – 60,000 psi | General-purpose, structural components |

| Medium Carbon Steel | ASTM A36 | 400 – 550 MPa | 58,000 – 80,000 psi | Construction, bridges, machinery |

| High Carbon Steel | ASTM A1044 | 700 – 1,000 MPa | 101,000 – 145,000 psi | Heavy-duty applications, automotive |

| Alloy Steel | ASTM A193 B7 | 825 – 1,035 MPa | 120,000 – 150,000 psi | High-pressure and high-temperature applications |

| Stainless Steel | A2 (304) | 520 – 750 MPa | 75,000 – 110,000 psi | Corrosion-resistant applications, food industry |

| Stainless Steel | A4 (316) | 500 – 750 MPa | 73,000 – 110,000 psi | Marine environments, chemical processing |

| Brass | ASTM B16 | 300 – 550 MPa | 43,000 – 80,000 psi | Decorative applications, low-strength fittings |

| Aluminum | 6061-T6 | 310 – 350 MPa | 45,000 – 50,000 psi | Lightweight applications, aerospace |

| Titanium | Grade 5 | 900 – 1,200 MPa | 130,000 – 175,000 psi | High-performance applications, aerospace |

Tensile Strength Values

Carbon Steel:

ASTM A307: 240 – 415 MPa (35,000 – 60,000 psi)

Medium Carbon Steel:

ASTM A36: 400 – 550 MPa (58,000 – 80,000 psi)

High Carbon Steel:

ASTM A1044: 700 – 1,000 MPa (101,000 – 145,000 psi)

Alloy Steel:

ASTM A193 B7: 825 – 1,035 MPa (120,000 – 150,000 psi)

Stainless Steel:

A2 (304): 520 – 750 MPa (75,000 – 110,000 psi)

A4 (316): 500 – 750 MPa (73,000 – 110,000 psi)

Brass:

ASTM B16: 300 – 550 MPa (43,000 – 80,000 psi)

Aluminum:

6061-T6: 310 – 350 MPa (45,000 – 50,000 psi)

Titanium:

Grade 5: 900 – 1,200 MPa (130,000 – 175,000 psi)

Typical Applications

Carbon Steel: Suitable for general-purpose applications and structural components.

Medium Carbon Steel: Ideal for construction, bridges, and machinery.

High Carbon Steel: Used in heavy-duty applications and automotive components.

Alloy Steel: Common in high-pressure and high-temperature environments.

Stainless Steel: Perfect for corrosion resistance in food, marine, and chemical industries.

Brass: Used in decorative and low-strength fittings.

Aluminum: Applied in lightweight and aerospace projects.

Titanium: Best for high-performance needs and aerospace applications.

Coatings

Zinc Plated: Corrosion resistance, commonly used for indoor applications.

Hot-Dip Galvanized: Superior corrosion resistance, suitable for outdoor and marine environments.

Black Oxide: Mild corrosion resistance, improves appearance and lubricity.

Plain: No coating, used in controlled environments.

Nickel Plated: Enhanced corrosion resistance and aesthetic appeal.

Applications of Stud Rods

Construction

In construction, stud rods are used to connect structural elements, such as beams and columns. They provide a strong, stable connection that can support heavy loads and withstand various environmental conditions.

Machinery

In machinery, stud rods are used to secure components and maintain precise alignment. Their ability to handle high stress and vibration makes them ideal for use in engines, conveyors, and other mechanical systems.

Automotive

Stud rods are commonly used in automotive applications for securing engine parts, suspension systems, and other critical components. Their durability and strength are essential for maintaining vehicle performance and safety.

For more information on high-quality Stud Rods and to find the perfect solution for your application, please contact us.

Jinan Welle Metal Products Co., Ltd (Welleshaft)

Website: www.welleshaft.com

Email: [email protected]

Phone: +86-156-5017-9596

Explore our range of durable and reliable Threaded&Stud Rods today!

Stud Rods vs. Threaded Rods

The terms “stud rod” and “threaded rod” are often used interchangeably, but there are some distinctions. Stud rods typically refer to rods with threads running along their entire length, while threaded rods can also include partially threaded options. Understanding these differences helps in selecting the right type for your application.

Stud Rod Price and Availability

The price of stud rods varies depending on factors such as material, size, and quantity. For bulk purchases and customized orders, it’s essential to contact a reliable supplier to get the best rates. Welleshaft offers competitive pricing and excellent value for high-quality stud rods.

Why Choose Welleshaft?

Welleshaft is a trusted global supplier and contract manufacturer specializing in high-quality stud rods and other essential components. With years of experience and a commitment to excellence, Welleshaft ensures that all products meet the highest standards of quality and performance. Whether you need fully threaded studs, partially threaded rods, or custom solutions, Welleshaft provides reliable and durable options for all your needs.

High-Quality Materials

At Welleshaft, we use only the finest materials to manufacture our stud rods, ensuring superior performance and longevity.

Customization Options

We offer a wide range of customization options, allowing you to choose the perfect stud rod for your specific needs.

Global Supply Chain

With a robust global supply chain, we can deliver stud rods to customers worldwide, ensuring timely delivery and excellent service.

Expertise and Experience

With 13 years of experience in the industry, Welleshaft has the expertise to provide high-quality stud rods that meet the exacting standards of our clients.

Frequently Asked Questions

What is a Stud Rod?

A stud rod is a long rod with threads running along its length, used for fastening and securing objects in construction, manufacturing, and engineering applications.

What is the Difference Between a Stud and a Thread?

A stud typically has threads on the ends, while a thread refers to the helical structure that allows for fastening. Studs can be partially or fully threaded.

What is a Stud Bolt Used For?

A stud bolt is used to fasten two objects together, providing a strong and secure connection.

What is the Difference Between a Rod and a Bolt?

A rod is a long, straight bar, while a bolt is a threaded fastener with a head, used in conjunction with a nut.

What Does a Stud Mean?

In the context of fasteners, a stud is a rod with threads used to secure objects together.

What Does Stud Mean in Metal?

In metalworking, a stud refers to a threaded rod used for fastening.

Is a Stud a Screw?

No, a stud is not a screw. A stud is a rod with threads, while a screw is a fastener with a helical thread and a head.

Is a Stud the Same as a Bolt?

No, a stud is different from a bolt. A bolt has a head and is used with a nut, while a stud is a rod with threads.

How Do I Identify a Stud?

A stud can be identified by its threaded ends and smooth middle section, depending on the type of stud.

What is the Purpose of a Stud Weld?

A stud weld is used to attach a stud to a metal surface, providing a strong and secure connection.

Why is a Horse Called a Stud?

In animal breeding, a stud refers to a male animal used for breeding purposes.

What is a Stud and Why is it Important?

A stud is a threaded rod used for fastening objects together, providing strength and stability in various applications.

What is the Difference Between a Bolt and a Stud?

A bolt has a head and is used with a nut, while a stud is a rod with threads and no head, used for fastening objects together.

Conclusion

Selecting the right stud rods is crucial for ensuring the reliability and durability of your projects. Whether you need fully threaded studs for construction, partially threaded rods for automotive applications, or custom solutions, Welleshaft is the trusted partner you can count on. With a wide range of products, competitive pricing, and exceptional quality, Welleshaft stands out as the global leader in stud rod manufacturing.

For more information on top-quality stud rods and to place your order, contact Welleshaft today. Discover how our reliable solutions can boost the performance and longevity of your applications.